Welding Brass Brazing Rod For HVAC System

Definition

Brass brazing alloy is a welding material with copper (Cu) as the basic component and an appropriate amount of zinc (Zn) added to form a brass body. In some specific brass brazing alloy formulas, it may also contain a small amount of other auxiliary elements, such as tin (Sn), lead (Pb), aluminum (Al), etc. The addition of these elements can further optimize the various properties of the alloy to better meet the needs of different brazing scenarios.

Material

Cu、Zn、Sn、Pb、Al

Advantages

① Moderate melting point and excellent fluidity: It can quickly fill the weld gap to ensure that the weld joint is dense and defect-free; at the same time, the alloy layer formed after welding has excellent tensile strength and corrosion resistance, and is suitable for dissimilar material connections of various metals such as copper, steel, and cast iron.

② Easy to operate: Efficient operation can be achieved by cooperating with conventional brazing process, and the workpiece surface is smooth after welding without complicated post-processing.

③ Good strength and hardness: After brazing, it can ensure that the connected parts have a certain ability to withstand external forces, which is convenient for processing during the brazing operation and can ensure that the joints after welding have sufficient wear resistance.

④ Good corrosion resistance: The parts brazed together can maintain good performance under different environmental conditions and extend their service life.

⑤ High Cost - effectiveness: The brass brazing rod is affordably priced. While ensuring welding quality, it effectively controls costs.

Application Scope

In the field of mechanical manufacturing, it is often used to connect various mechanical parts to ensure the stability of the overall structure of mechanical equipment;

In the electronic equipment manufacturing industry, it can be used to connect some precision electronic components to ensure the stability of circuit connections;

In the field of architectural decoration, it is also used to connect some metal decorative components, etc., to achieve beautiful and firm connections.

Product Paramenters

|

Standard |

Item |

Alloy |

Chemical Composition |

|

ISO24373 |

Cu4641 |

CuZn40SnSi |

Cu:58.0~62.0 Al:0.01 Fe:0.2 Mn:0.3 Ni:~ P~ Pb:0.03 Si:0.1~0.5 Sn:1.0 Zn:bal. Other:0.2 |

|

GB/T9460 |

SCu6810A |

CuZn40SnSi |

Cu:58.0~62.0 Al:max 0.01 Fe:max 0.2 Mn:max 0.3 Ni:~ P~ Pb:max0.03 Si:0.1~0.5 Sn:max 1.0 Zn:bal. Other:max 0.2 |

|

BS EN14640 |

SCu6810 |

CuZn40SnSi |

Cu:58.0~62.0 Al:0.01 Fe:0.2 Mn:0.3 Ni:~ P~ Pb:0.03 Si:0.1~0.5 Sn:1.0 Zn:bal. Other:0.2 |

|

DIN 1733 |

2.0366 |

SG-CuZn40SnSi |

Cu:58.0~62.0 Al:max 0.01 Fe:max 0.2 Mn:max 0.3 Ni:~ P~ Pb:max 0.03 Si:0.1~0.5 Sn:max 1.0 Zn:bal. Other:max 0.2 |

Product Size

| Brass Brazing Rods Size |

|

1.5mm(0.059”) |

|

2.0mm(0.079”) |

|

2.5mm(0.098”) |

|

3.0mm(0.118”) |

|

4.0mm(0.157”) |

|

5.0mm(0.197”) |

|

6.0mm(0.236”) |

|

8.0mm(0.315”) |

Note: All sizes are Taojun standard, other sizes can be produced according to customer requirements.

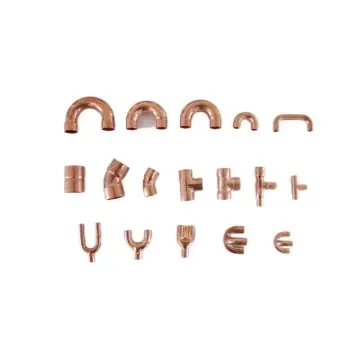

Photos

In general, brass brazing alloy is such an alloy material with diverse composition, excellent performance, good brazing characteristics and wide application, playing an indispensable role in the connection process of many industries.

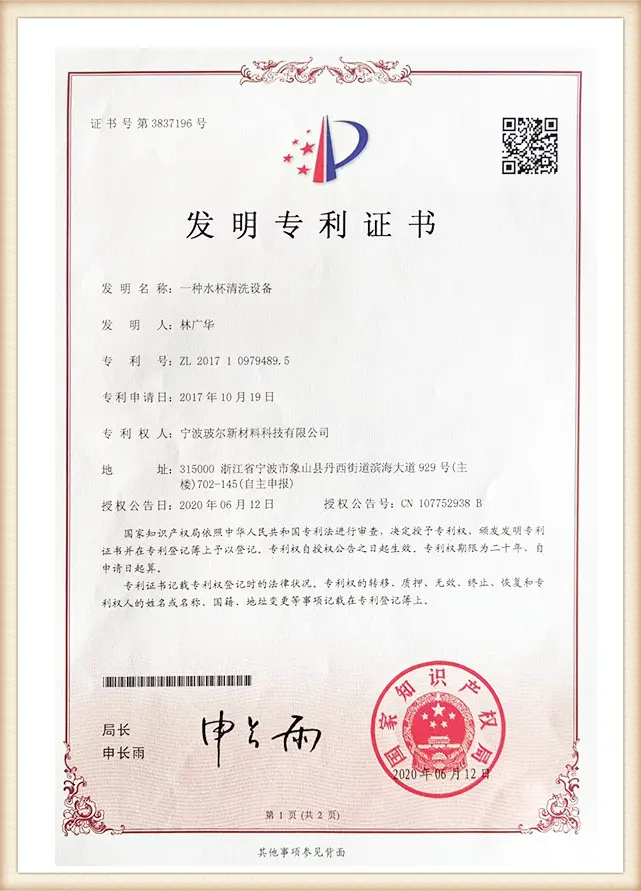

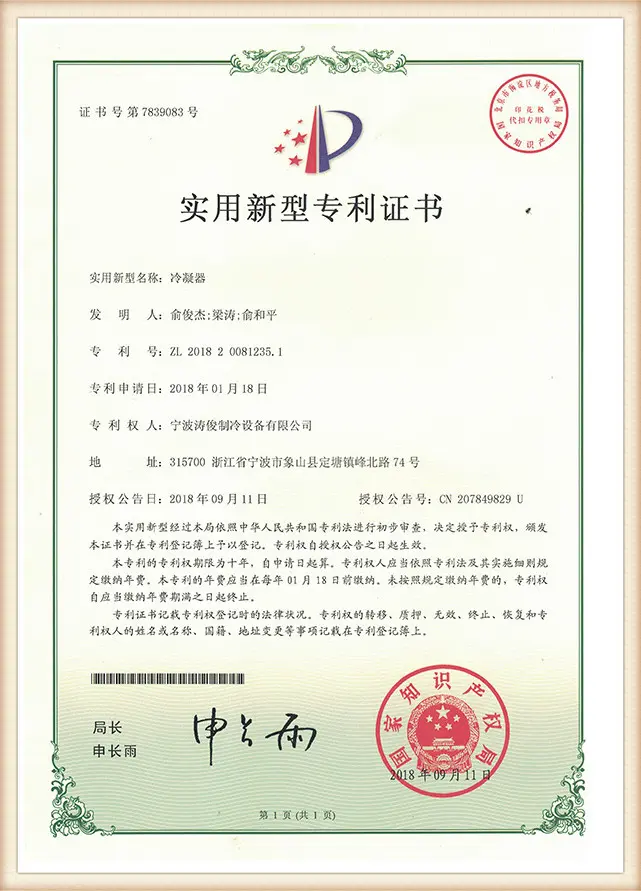

Certificates