Wholesale Liquid Line Filter Driers for Refrigeration Systems - Reliable Supplier Factory

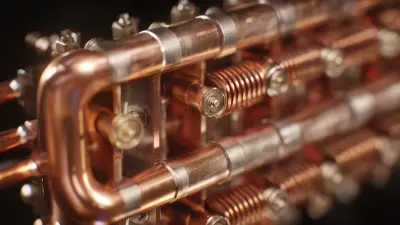

Maintaining optimal performance in refrigeration systems is crucial, and our Liquide Line Filter Drier plays a vital role. Engineered to effectively eliminate contaminants and moisture, this filter drier ensures your systems operate efficiently and dependably. As a wholesaler, we are committed to providing high-quality products from reputable manufacturers, guaranteeing excellent value for your investment. Our dedication to customer satisfaction sets us apart from the competition. Through our partnership with Ningbo Taojun Refrigeration Equipment Co., Ltd., we ensure exceptional quality backed by extensive industry experience. Our filter driers are designed for durability and performance, making them an ideal choice for B2B purchasers in need of trustworthy suppliers.7 Key Tips To Refrigeration Systems Liquid Line Filter Drier Service Backed by Expertise Your Trusted OEM Partner

Efficient refrigeration systems are vital for preserving food and sensitive products across various industries. A key component in these systems is the liquid line filter drier. Proper maintenance and servicing of this component can significantly enhance the overall performance and longevity of your refrigeration system. Here are seven essential tips to guide you through effective liquid line filter drier service, ensuring optimal efficiency and reliability. First, regularly inspect your filter drier for any signs of wear, damage, or clogging. A compromised filter can lead to increased pressure drops and adversely affect the refrigeration cycle. Additionally, it’s crucial to replace the filter drier during routine maintenance or when major repairs are undertaken. Choose quality products that meet industry standards, ensuring you’re backed by a trusted OEM partner with expertise in refrigeration solutions. Moreover, keep an eye on the system's refrigerant levels. Insufficient refrigerant can overburden the filter drier, leading to premature failure. Implementing a proactive maintenance schedule, including regular refrigerant checks, allows you to ensure consistent performance. Lastly, never overlook the importance of professional servicing and support. Consulting with experts in refrigeration systems can provide invaluable insights tailored to your specific needs, ensuring your system operates at peak efficiency.

7 Key Tips To Refrigeration Systems Liquid Line Filter Drier Service Backed by Expertise Your Trusted OEM Partner

| Tip # | Tip Description | Recommended Frequency | Expert Insights |

|---|---|---|---|

| 1 | Inspect for leaks and corrosion. | Quarterly | Preventive maintenance reduces the risk of system failure. |

| 2 | Check filter drier condition. | Biannually | A clogged filter can decrease efficiency and increase operating costs. |

| 3 | Replace filter drier as needed. | Every 2-3 years | Always use OEM replacement parts for optimal performance. |

| 4 | Monitor refrigerant levels. | Monthly | Low refrigerant can indicate leaks, check regularly. |

| 5 | Ensure proper airflow through the system. | Monthly | Obstructed airflow can strain the system, leading to failures. |

| 6 | Regularly clean condenser and evaporator coils. | Annually | Dirty coils can reduce system efficiency by up to 30%. |

| 7 | Train staff on system operation and maintenance. | Annually | Knowledgeable staff can prevent many common issues. |

Expert Choice of Refrigeration Systems Liquid Line Filter Drier Manufacturer From Concept to Delivery

J

Jessica Green

Wonderful purchase experience! Their knowledgeable staff really helped me understand the product better.

20 June 2025

D

David Campbell

I am very pleased with my purchase! Their support was knowledgeable and efficient.

06 June 2025

A

Angela Parker

Great quality and amazing after-sales support! The team really knows their stuff.

20 May 2025

N

Natalie Lee

Outstanding service! The quality of the product is first-rate.

28 May 2025

A

Alexander Gray

Top-notch product! The professionalism of the after-sales service really stands out.

15 May 2025

R

Ryan Long

Top-tier quality! The customer service was prompt and went above expectations.

06 June 2025