Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

Why Your Refrigeration System Needs a High-Efficiency Finned Tube Condenser

High-efficiency finned tube condensers play a critical role in optimizing refrigeration system components. Their advanced designs enhance heat transfer rates by up to 15%, improving energy efficiency and reducing operational costs. Systems using these condensers demonstrate evaporation heat transfer coefficients that are 111–207% higher than traditional smooth tubes, showcasing their superior performance. By minimizing energy waste and stabilizing operations, these condensers help refrigeration systems achieve consistent cooling while cutting long-term expenses. Their innovative engineering ensures better reliability and a reduced environmental footprint, making them an essential upgrade for modern refrigeration systems.

Key Takeaways

- Finned tube condensers move heat better, saving up to 15% energy.

- They use less power, cutting electricity costs by up to 30%.

- Strong materials make them last longer and need less fixing.

- These condensers lower harmful gases, helping the planet stay healthy.

- They make refrigeration systems last longer, so fewer replacements are needed.

- Spending money on these condensers saves more over time than they cost.

- Picking a condenser means checking how it works, its strength, and if it fits.

- Taking care of condensers keeps them working well and lasting longer.

Understanding Refrigeration System Components

Role of Condensers in Refrigeration Systems

Condensers are vital components in refrigeration systems. They are responsible for releasing heat absorbed during the cooling process, ensuring the system maintains optimal performance. By converting high-pressure refrigerant vapor into liquid, condensers facilitate efficient heat exchange. This process prevents overheating and ensures consistent cooling across various applications, from commercial refrigeration to industrial systems.

The efficiency of a condenser directly impacts the overall performance of refrigeration system components. For instance, the coefficient of performance (COP) increases by 8.9% when using advanced refrigerant mixtures compared to traditional options like R134a. Additionally, systems with high-efficiency condensers demonstrate a 26.8% reduction in total equivalent warming impact (TEWI), highlighting their role in minimizing environmental harm. Daily energy consumption also decreases by 5.9%, showcasing the energy-saving potential of modern condensers.

To better understand performance benchmarks, the table below outlines industry standards for various refrigeration components:

| Component Type | Standard Reference | Description |

|---|---|---|

| Self-Contained/Remote Display Units | ANSI/AHRI 1200 (I-P)-2013 | Performance Rating of Commercial Refrigerated Display Merchandisers and Storage Cabinets |

| Transport Refrigeration | ANSI/AHRI 1110 (I-P)-2013 | Performance Rating of Mechanical Transport Refrigeration Units |

| Unit Coolers | AHRI Standard 420 (I-P)-2016 | Performance Rating of Forced-Circulation Free-Delivery Unit Coolers for Refrigeration |

| Walk-in Coolers/Freezers | ANSI/AHRI 1250 (I-P)-2014 | Performance Rating of Walk-in Coolers and Freezers |

| Condensing Units | AHRI 450-2007 | Performance Rating of Water-cooled Refrigerant Condensers, Remote Type |

Importance of High-Efficiency Components

High-efficiency components are essential for modern refrigeration systems. They reduce energy consumption, improve system reliability, and lower operational costs. For example, the Power Usage Effectiveness (PUE) metric demonstrates the importance of efficiency. While the average PUE for data centers is around 1.8, high-efficiency systems achieve values as low as 1.2. The National Renewable Energy Laboratory (NREL) has achieved an impressive PUE of 1.036, showcasing the potential of advanced components to optimize energy use.

In refrigeration systems, high-efficiency components like finned tube condensers enhance heat transfer and reduce energy waste. These components also contribute to environmental sustainability by lowering greenhouse gas emissions. Systems equipped with advanced condensers operate more consistently, ensuring reliable performance over time. Furthermore, they require less maintenance, reducing downtime and repair costs.

Tip: Investing in high-efficiency refrigeration system components not only improves performance but also delivers long-term savings. Businesses can achieve significant reductions in energy bills and maintenance expenses by upgrading to advanced technologies.

By integrating high-efficiency components, refrigeration systems can meet modern performance demands while minimizing their environmental footprint. This makes them an indispensable choice for businesses seeking sustainable and cost-effective solutions.

What is a High-Efficiency Finned Tube Condenser?

Definition and Core Features

A high-efficiency finned tube condenser is an advanced heat exchange device designed to optimize the performance of refrigeration systems. It uses a combination of tubes and fins to maximize the surface area available for heat transfer. This design ensures that heat dissipates more effectively, improving the overall efficiency of the system. These condensers are engineered to handle higher thermal loads while maintaining compact dimensions, making them suitable for both commercial and industrial applications.

Key features of high-efficiency finned tube condensers include enhanced heat transfer coefficients, reduced pressure drops, and improved energy efficiency. Their innovative design minimizes thermal resistance, allowing refrigeration systems to operate at peak performance. Additionally, these condensers are built to withstand varying environmental conditions, ensuring durability and consistent operation over time.

Note: The integration of high-efficiency finned tube condensers into refrigeration system components significantly enhances cooling performance and reduces energy consumption.

Materials Used in Finned Tube Condensers

The materials used in finned tube condensers play a crucial role in determining their efficiency and durability. Copper and aluminum are the most commonly used materials due to their excellent thermal conductivity and corrosion resistance. Copper offers superior thermal conductivity and slightly higher fin efficiency compared to aluminum. However, aluminum is more cost-effective and lightweight, making it a popular choice for large-scale applications.

- Copper exhibits better thermal conductivity and slightly higher fin efficiency than aluminum.

- The difference in fin efficiency between copper and aluminum is minimal under identical conditions.

- Aluminum tubes have 4%-12% lower heat transfer and 7%-9% lower heat transfer coefficients compared to copper tubes.

- Aluminum-aluminum exchangers achieve 67% higher heat transfer than copper-aluminum exchangers at only 8% of the cost.

The choice of material depends on the specific requirements of the refrigeration system, such as cost constraints, thermal performance, and environmental conditions. Both copper and aluminum offer unique advantages, allowing manufacturers to tailor condensers to meet diverse application needs.

Comparison with Traditional Condensers

High-efficiency finned tube condensers outperform traditional condensers in several key areas. Their advanced design reduces energy consumption and enhances heat transfer, making them a superior choice for modern refrigeration systems. The table below highlights the comparative performance metrics between high-efficiency finned tube condensers and their traditional counterparts:

| Metric | High-Efficiency Finned Tube | Traditional Counterpart | Difference (%) |

|---|---|---|---|

| Heat Transfer Coefficient | Decreased by 19% | Baseline | -19 |

| Pressure Drop | Decreased by 36% | Baseline | -36 |

These improvements translate to significant energy savings and reduced operational costs. High-efficiency condensers also exhibit lower pressure drops, which minimizes the workload on compressors and extends the lifespan of refrigeration system components. By upgrading to these advanced condensers, businesses can achieve better performance, lower maintenance requirements, and a reduced environmental footprint.

Benefits of High-Efficiency Finned Tube Condensers

Energy Savings and Efficiency

High-efficiency finned tube condensers significantly reduce energy consumption in refrigeration systems. Their advanced design minimizes thermal resistance, allowing systems to operate with less energy while maintaining optimal cooling performance. By improving the heat exchange process, these condensers reduce the workload on compressors, which are among the most energy-intensive refrigeration system components. This leads to lower electricity bills and a smaller carbon footprint.

The energy savings achieved by these condensers are particularly beneficial for businesses with high refrigeration demands. For example, commercial facilities that upgrade to high-efficiency condensers often report noticeable reductions in their monthly energy expenses. These savings not only offset the initial investment but also contribute to long-term operational cost reductions.

Tip: Businesses aiming to improve energy efficiency should consider integrating high-efficiency finned tube condensers into their refrigeration systems. This upgrade offers both financial and environmental benefits.

Enhanced Heat Transfer

The innovative design of high-efficiency finned tube condensers enhances heat transfer performance, making them a superior choice for modern refrigeration systems. Their unique fin structures, such as discontinuous, staggered, and vortex-generator types, increase the surface area available for heat exchange. This results in improved thermal conductivity and faster cooling cycles.

The table below highlights the quantified improvements in heat transfer associated with different fin structures:

| Type of Fin Structure | Average Nusselt Number Increase | Average Friction Factor Increase |

|---|---|---|

| Discontinuous Type | 11.29% | 3.23% |

| Staggered Type | 28.61% | 66.26% |

| Vortex-Generator Type | 56.46% | 48.58% |

These enhancements are further supported by technical evaluations of advanced designs like Vipertex EHT tubes. These tubes demonstrate performance gains exceeding 100% compared to traditional smooth tubes. The improvements stem from increased fluid turbulence, secondary flow generation, boundary layer disruption, and additional heat transfer surface area. Moreover, the Vipertex design minimizes fouling effects, ensuring consistent heat transfer efficiency over time.

By adopting high-efficiency finned tube condensers, refrigeration systems achieve superior cooling performance, even under demanding conditions. This makes them an ideal solution for industries requiring precise temperature control.

Reduced Maintenance Costs

High-efficiency finned tube condensers not only improve performance but also reduce maintenance costs. Their robust construction and advanced materials, such as corrosion-resistant copper and aluminum, ensure durability and longevity. These features minimize the likelihood of system failures and the need for frequent repairs.

The reduced pressure drops in these condensers also play a crucial role in lowering maintenance expenses. By decreasing the strain on compressors and other refrigeration system components, these condensers extend the lifespan of the entire system. This translates to fewer breakdowns and less downtime, allowing businesses to maintain uninterrupted operations.

Additionally, the innovative designs of these condensers resist fouling and scaling, which are common issues in traditional systems. This resistance reduces the frequency of cleaning and maintenance, further cutting costs. Over time, the savings from reduced maintenance contribute to the overall cost-effectiveness of high-efficiency finned tube condensers.

Note: Investing in high-efficiency condensers not only enhances system performance but also provides long-term financial benefits by reducing repair and maintenance needs.

Environmental Impact

High-efficiency finned tube condensers play a pivotal role in reducing the environmental footprint of refrigeration systems. Their advanced design and superior performance contribute to sustainability in several key ways.

1. Lower Greenhouse Gas Emissions

Refrigeration systems equipped with high-efficiency finned tube condensers consume less energy. This reduction in energy usage directly translates to lower greenhouse gas (GHG) emissions. Since electricity generation often relies on fossil fuels, minimizing energy consumption helps decrease carbon dioxide (CO₂) and other harmful emissions.

- Key Statistics:

- Systems with high-efficiency condensers can reduce energy consumption by up to 30%.

- A 10% improvement in energy efficiency can lower CO₂ emissions by approximately 1.5 million metric tons annually in the commercial refrigeration sector alone.

Did You Know? The International Energy Agency (IEA) estimates that improving energy efficiency in cooling systems could prevent the release of 460 billion metric tons of CO₂ by 2050.

2. Reduced Refrigerant Leakage

High-efficiency finned tube condensers are designed with robust materials like copper and aluminum, which enhance durability and minimize the risk of refrigerant leaks. Refrigerants, such as hydrofluorocarbons (HFCs), have a high global warming potential (GWP). Even small leaks can significantly impact the environment.

- Environmental Benefits:

- Reduced refrigerant leakage lowers the system's total equivalent warming impact (TEWI).

- Advanced condensers support the transition to low-GWP refrigerants, aligning with global climate goals.

3. Support for Renewable Energy Integration

The energy efficiency of these condensers complements renewable energy sources like solar and wind. By reducing the overall energy demand, refrigeration systems can operate more effectively on renewable energy grids. This synergy accelerates the shift toward cleaner energy solutions.

Tip: Businesses adopting high-efficiency condensers can achieve dual benefits—lower operational costs and alignment with sustainability initiatives.

4. Waste Reduction and Longevity

The durable construction of high-efficiency finned tube condensers extends their lifespan, reducing the frequency of replacements. This longevity minimizes waste generation and conserves resources used in manufacturing.

| Aspect | Traditional Condensers | High-Efficiency Condensers |

|---|---|---|

| Average Lifespan | 8-10 years | 12-15 years |

| Material Recyclability | Moderate | High |

| Replacement Frequency | Higher | Lower |

5. Contribution to Global Sustainability Goals

The adoption of high-efficiency finned tube condensers aligns with international efforts to combat climate change. Initiatives like the Kigali Amendment to the Montreal Protocol emphasize the importance of reducing HFC usage and improving energy efficiency in cooling systems. These condensers support such goals by offering a practical solution for sustainable refrigeration.

Call to Action: Upgrading to high-efficiency finned tube condensers is not just a financial decision—it is an investment in a greener future. Businesses and industries can lead the way in environmental stewardship by embracing this innovative technology.

By integrating high-efficiency finned tube condensers, refrigeration systems can achieve superior performance while significantly reducing their environmental impact. This makes them an essential component for businesses striving to balance operational efficiency with sustainability.

Performance Improvements in Refrigeration Systems

Optimized Cooling Efficiency

High-efficiency finned tube condensers significantly enhance the cooling performance of refrigeration systems. Their advanced design optimizes heat transfer by increasing the surface area available for thermal exchange. This improvement reduces thermal resistance, enabling refrigeration systems to maintain consistent cooling even under demanding conditions. For instance, the coefficient of performance (COP) can increase by 7%, resulting in substantial energy savings without additional costs. Additionally, systems with these condensers achieve cost reductions of up to 33% when maintaining a constant COP.

The impact of airflow conditions on cooling efficiency further highlights the importance of these condensers. Under low or moderate nonuniform airflow, effectiveness deteriorates by only 5% to 10%, while pressure drop increases by 10% to 20%. In contrast, severely nonuniform airflow can cause up to a 30% reduction in effectiveness and a 90% increase in pressure drop. These metrics underscore the reliability of high-efficiency finned tube condensers in maintaining optimal performance across various operating conditions.

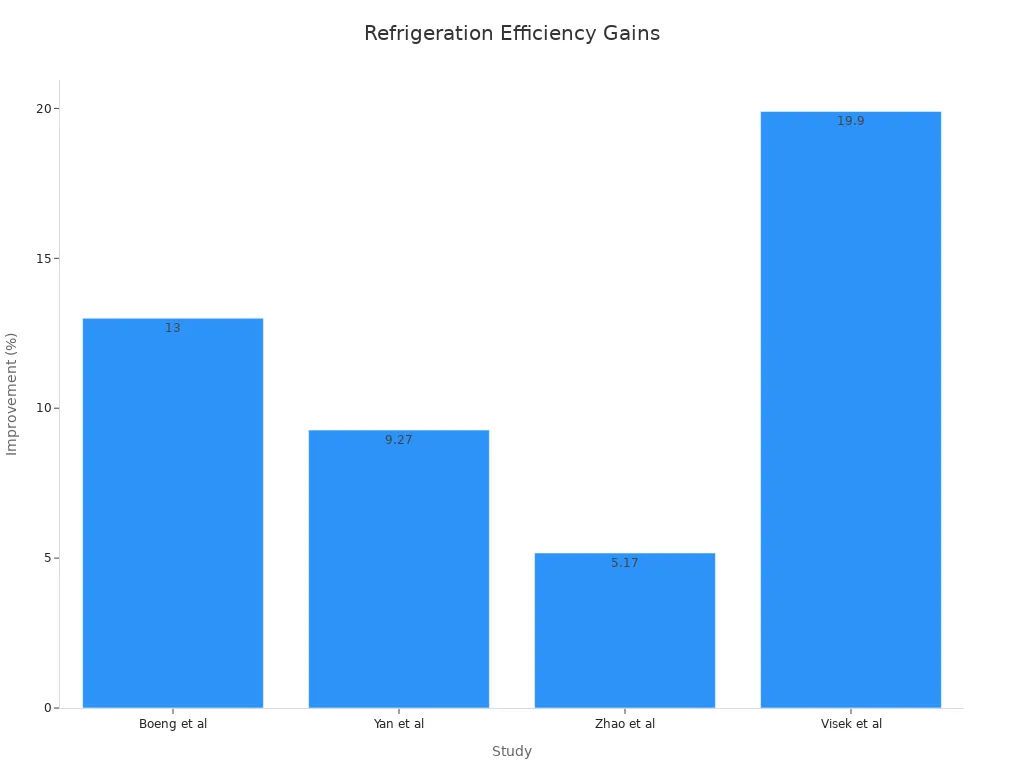

The table below summarizes documented improvements in energy efficiency achieved through high-efficiency components:

| Study | Improvement in Energy Efficiency | Year |

|---|---|---|

| Boeng et al. | Up to 13% reduction in energy consumption | 2020 |

| Yan et al. | 9.27% energy reduction | 2020 |

| Fang et al. | 30.4% improvement in COP and exergy efficiency | 2019 |

| Visek et al. | 19.9% reduction in energy consumption | 2014 |

These findings demonstrate the transformative potential of high-efficiency finned tube condensers in optimizing cooling efficiency.

Prolonged System Lifespan

Refrigeration systems equipped with high-efficiency finned tube condensers benefit from extended operational lifespans. The use of corrosion-resistant coatings and durable materials, such as copper and aluminum, enhances the reliability of these condensers. This durability reduces the likelihood of component failure, minimizing maintenance costs and system downtime. Enhanced heat transfer surfaces also contribute to superior thermal performance, ensuring that the system operates efficiently over a longer period.

The compact and cost-effective design of these condensers further supports longevity. By reducing the strain on compressors and other refrigeration system components, they prevent premature wear and tear. This not only extends the lifespan of individual components but also improves the overall reliability of the system.

Consistent and Reliable Operation

High-efficiency finned tube condensers ensure consistent and reliable operation by maintaining stable performance metrics. Key reliability indicators, such as the coefficient of performance (COP) and energy efficiency ratio (EER), demonstrate the effectiveness of these condensers in delivering consistent cooling. For example, systems with high-efficiency condensers exhibit higher refrigeration capacity and lower compressor discharge temperatures, preventing overheating and ensuring smooth operation.

The table below highlights critical reliability metrics for refrigeration systems:

| Metric | Description |

|---|---|

| Coefficient of Performance (COP) | Compares refrigeration effect produced to energy consumed; higher values indicate efficiency. |

| Energy Efficiency Ratio (EER) | Measures cooling capacity relative to power input; higher values signify better efficiency. |

| Refrigeration Capacity | Indicates the system's ability to remove heat; essential for meeting cooling loads. |

| Compressor Discharge Temperature | Monitored to prevent overheating; indicates inefficiencies or malfunctions. |

| Mean Time Between Failure (MTBF) | Average time between system failures; assesses reliability. |

By maintaining optimal suction pressure, temperature, and superheat levels, these condensers ensure that refrigeration systems operate without interruptions. This reliability minimizes downtime, enhances productivity, and reduces the risk of costly repairs.

Cost and Long-Term Savings

Initial Investment vs. Long-Term Benefits

High-efficiency finned tube condensers require a higher initial investment compared to traditional options. Their advanced design and use of premium materials, such as copper and aluminum, contribute to the upfront cost. However, this initial expense is offset by substantial long-term savings. These condensers deliver enhanced energy efficiency, reducing operational costs over time. Businesses often find that the return on investment (ROI) justifies the initial expenditure.

The table below highlights the cost dynamics of high-efficiency finned tube condensers:

| Aspect | Details |

|---|---|

| Initial Investment | Higher initial costs for high-efficiency finned tube condensers. |

| Long-term Savings | Significant savings due to reduced energy consumption and lower maintenance costs. |

| Energy Efficiency | Enhanced heat transfer efficiency leads to lower utility bills. |

| Maintenance Costs | Generally lower due to durable design and resistance to fouling. |

| Return on Investment (ROI) | Substantial energy efficiency returns provide compelling ROI over time. |

| Economic Benefits | Long-term economic benefits make finned tubes a viable option for optimizing heat exchange. |

Tip: Businesses should evaluate the total cost of ownership rather than focusing solely on initial expenses. This approach ensures a clearer understanding of long-term financial benefits.

Energy Cost Reduction

Energy efficiency is one of the most significant advantages of high-efficiency finned tube condensers. Their innovative design minimizes thermal resistance, allowing refrigeration systems to consume less energy. This reduction directly translates to lower utility bills. For businesses with high refrigeration demands, such as supermarkets or industrial facilities, these savings can be substantial.

For example, systems equipped with these condensers often report energy consumption reductions of up to 30%. This improvement not only lowers operational costs but also aligns with sustainability goals by reducing greenhouse gas emissions. Over time, the cumulative energy savings can far exceed the initial investment, making these condensers a cost-effective choice.

Did You Know? A 10% improvement in energy efficiency can save businesses thousands of dollars annually, depending on the scale of their refrigeration systems.

Lower Repair and Maintenance Expenses

The durable construction of high-efficiency finned tube condensers reduces the need for frequent repairs. Materials like copper and aluminum resist corrosion and fouling, common issues in traditional systems. This durability minimizes wear and tear, extending the lifespan of the condenser and other system components.

Additionally, these condensers experience lower pressure drops, which reduces the strain on compressors. This feature not only enhances system reliability but also decreases the likelihood of costly breakdowns. Businesses benefit from fewer maintenance interruptions, ensuring smoother operations and lower repair expenses.

By investing in high-efficiency condensers, businesses can achieve a balance between performance and cost-effectiveness. The reduced maintenance requirements further enhance their appeal as a long-term solution for refrigeration systems.

Call to Action: Upgrading to high-efficiency finned tube condensers is a strategic decision that delivers financial and operational benefits. Businesses should consider this investment to optimize their refrigeration systems and reduce long-term costs.

Selecting the Right Finned Tube Condenser

Factors to Consider

Choosing the right finned tube condenser requires careful evaluation of several critical factors. These considerations ensure optimal performance, energy efficiency, and long-term reliability. Businesses should focus on the following:

- Thermal Performance: The condenser's ability to transfer heat efficiently is paramount. Features like slit fins with longitudinal vortices or vortex generators can significantly enhance heat transfer. For example, slit fins improve the JF-factor by 15.8%, while vortex generators increase heat transfer by 8.74%.

- Material Durability: Copper and aluminum are common materials due to their excellent thermal conductivity and corrosion resistance. The choice between these materials depends on the system's environmental conditions and budget constraints.

- Airflow Distribution: Uniform airflow distribution is essential for consistent performance. Studies show that nonuniform airflow can reduce efficiency by 5%–10% and increase pressure drop by 10%–20%.

- Design Features: Advanced configurations, such as staggered arrangements or louvered folding fins, enhance cooling efficiency. Staggered arrangements, for instance, improve convective heat transfer coefficients by 20%–25%.

Tip: Businesses should prioritize condensers with optimized fin pitch and wave fins, as these designs improve performance by up to 34.2%.

Compatibility with System Requirements

A finned tube condenser must align with the specific requirements of the refrigeration system. Compatibility ensures seamless integration and maximizes operational efficiency. Key aspects to evaluate include:

- Refrigerant Type: The condenser must support the refrigerant used in the system. Research by Domanski and Yashar (2006) highlights that high-pressure refrigerants perform better with optimized heat exchangers.

- System Capacity: The condenser's capacity should match the cooling load of the system. Oversized or undersized condensers can lead to inefficiencies and increased energy consumption.

- Operating Conditions: Environmental factors, such as temperature and humidity, influence condenser performance. Systems operating in extreme conditions may require specialized designs with enhanced durability.

- Air and Fluid Distribution: Proper alignment of air and fluid distribution is critical for heat exchanger performance. Studies indicate that compatibility in these areas minimizes losses and ensures consistent cooling.

Note: Businesses should consult system specifications and performance benchmarks to ensure compatibility before making a selection.

Evaluating Quality and Efficiency

Assessing the quality and efficiency of a finned tube condenser involves examining performance benchmarks and adherence to industry standards. The following metrics provide valuable insights:

| Benchmark/Standard | Description |

|---|---|

| Friction Power Ratio (FPR) | Measures friction power reduction between two heat exchangers with equal heat flux. |

| Penalty Factor (PF) | Accounts for saturation temperature drop and driving temperature difference. |

| Minimum Entropy Generation (Ns) | Indicates losses in the condenser based on thermodynamic principles. |

High-quality condensers often feature advanced designs, such as internal fins, which enhance radial heat uniformity and waste heat recovery. Additionally, airflow velocity and distribution play a crucial role. Uniform airflow ensures consistent performance, while excessive velocity may increase the risk of freezing.

Call to Action: Businesses should prioritize condensers that meet these benchmarks and incorporate innovative features to achieve superior efficiency and reliability.

By considering these factors, businesses can select a finned tube condenser that aligns with their operational needs, enhances system performance, and delivers long-term value.

High-efficiency finned tube condensers offer transformative benefits for refrigeration systems. They enhance energy efficiency, with the coefficient of performance (COP) increasing by up to 29% and sub-cooling improving by 24%. These condensers also deliver significant cost savings, as demonstrated by a 12.48% peak life cycle payback ratio.

| Case | Daily Energy Saving Ratio (DESR) | Hybrid Power Source Savings |

|---|---|---|

| 3 | 9.3% | 17.5% |

| 9 | 5.4% | 11.4% |

Upgrading to these advanced components ensures better performance, reduced costs, and environmental sustainability. Businesses should evaluate their systems and embrace this innovative solution to achieve long-term success.

FAQ

1. What is the primary purpose of a finned tube condenser?

A finned tube condenser enhances heat transfer by increasing the surface area for thermal exchange. This design improves cooling efficiency and reduces energy consumption in refrigeration systems.

2. How does a high-efficiency finned tube condenser save energy?

Its advanced design minimizes thermal resistance and optimizes heat transfer. This reduces the workload on compressors, leading to lower energy consumption and operational costs.

3. What materials are commonly used in finned tube condensers?

Manufacturers typically use copper and aluminum. Copper offers superior thermal conductivity, while aluminum is lightweight and cost-effective, making both suitable for various applications.

4. Are high-efficiency finned tube condensers environmentally friendly?

Yes, they reduce energy usage and greenhouse gas emissions. Their durable construction also minimizes waste and supports the use of low-GWP refrigerants, aligning with sustainability goals.

5. How do these condensers improve system reliability?

Their robust materials and innovative designs resist corrosion, fouling, and pressure drops. This durability extends the lifespan of refrigeration systems and ensures consistent performance.

6. What industries benefit most from high-efficiency finned tube condensers?

Industries with high refrigeration demands, such as food storage, pharmaceuticals, and manufacturing, benefit significantly. These condensers ensure precise temperature control and cost savings.

7. How do I choose the right finned tube condenser for my system?

Consider factors like thermal performance, material durability, refrigerant compatibility, and system capacity. Consulting with experts ensures the best match for specific operational needs.

8. What is the lifespan of a high-efficiency finned tube condenser?

These condensers typically last 12-15 years, depending on usage and maintenance. Their durable construction reduces the need for frequent replacements, offering long-term value.

Tip: Regular maintenance maximizes the lifespan and efficiency of your condenser.