Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

Why Rolling Bundy Tube Copper Pipe Delivers Precision in Refrigeration Applications

Rolling Bundy Tube Copper Pipe for Fridge Coiling air Conditioner Tube, developed by Taojun HVAC, exemplifies engineering precision. Its advanced double-layer structure and cutting-edge manufacturing processes make it a reliable choice for refrigeration systems. The pipe’s high strength and exceptional dimensional accuracy ensure consistent performance in demanding applications. Its clean internal surface enhances refrigerant flow efficiency, making it indispensable for modern cooling technologies. With durability and cost-effectiveness at its core, this copper pipe sets a new standard for refrigeration solutions.

Key Takeaways

- Bundy Tube copper pipes have two layers for extra strength.

- This makes them perfect for high-pressure cooling systems.

- Rolling technology keeps pipe sizes accurate for better refrigerant flow.

- This helps cooling systems work well and save energy.

- The clean inside of the pipes stops clogs and saves power.

- They resist rust, so they last longer and need less fixing.

- This saves money over time with fewer repairs needed.

- Bundy Tube pipes can be shaped for tricky cooling designs.

- They fit many systems and are very flexible to use.

Unique Features of Rolling Bundy Tube Copper Pipe for Fridge Coiling air Conditioner Tube

Double-Layer Structure for Enhanced Strength

The Rolling Bundy Tube Copper Pipe for Fridge Coiling air Conditioner Tube features a double-layer structure that significantly enhances its strength and durability. This innovative design ensures the pipe can withstand high-pressure environments and resist mechanical stress over extended periods. Research on double-layer grids highlights their ability to improve functional capabilities under demanding service conditions. This approach aligns with the Bundy Tube's design, which prioritizes durability and performance.

Additionally, studies on double-layered artificial chordae demonstrate how such structures boost mechanical strength, enabling resistance to high tensile loads while minimizing rupture risks. The hydrophobic surface layer further enhances long-term functionality by reducing adhesion. These findings underscore the advantages of the double-layer structure in ensuring the Bundy Tube's reliability in refrigeration systems.

Precision Rolling Technology for Accurate Dimensions

Precision rolling technology plays a pivotal role in the manufacturing of the Rolling Bundy Tube Copper Pipe for Fridge Coiling air Conditioner Tube. This advanced process ensures exceptional accuracy in both outer diameter and wall thickness, which is critical for maintaining consistent performance in refrigeration applications.

The technology achieves remarkable dimensional precision, as confirmed by technical measurements:

| Measurement Aspect | Specification |

|---|---|

| Part to part diameter variation | .005 to .008 mm (.0002 to .0003 in.) |

| Lead variation per 25 mm rolled length | .002 mm per 25 mm (.00008 in. per inch) |

| Control of workpiece pitch and root diameters | Directly controlled by die positioning |

Such precise control over dimensions guarantees good concentricity, making the Bundy Tube an ideal choice for applications requiring exact measurements. This level of accuracy ensures efficient refrigerant flow and minimizes energy losses, enhancing the overall performance of refrigeration systems.

Clean Internal Surface for Efficient Refrigerant Transport

The internal surface of the Rolling Bundy Tube Copper Pipe for Fridge Coiling air Conditioner Tube is meticulously cleaned during the manufacturing process. This ensures minimal residue, which is essential for efficient refrigerant transport. The use of lubricating oil with low carbon content during production results in an exceptionally clean internal surface.

A clean internal environment reduces the risk of blockages and enhances the efficiency of refrigerant cycles. This feature is particularly important in modern refrigeration systems, where even minor inefficiencies can lead to increased energy consumption. By maintaining a pristine internal surface, the Bundy Tube supports optimal system performance and contributes to long-term reliability.

Practical Advantages in Refrigeration Applications

High Strength and Anti-Vibration Fatigue Limit

The Rolling Bundy Tube Copper Pipe for Fridge Coiling air Conditioner Tube demonstrates exceptional strength and resistance to vibration fatigue. Its double-layer structure enhances its ability to withstand high-pressure environments and mechanical stress. This feature ensures stability in refrigeration systems, even under challenging conditions.

The pipe’s anti-vibration fatigue limit plays a crucial role in maintaining system integrity. By resisting repeated stress cycles, it minimizes the risk of material failure. This durability is particularly valuable in applications where consistent performance is essential, such as in air conditioning systems and fridge coiling. The pipe’s ability to endure prolonged operational demands makes it a reliable choice for industries requiring robust piping solutions.

Corrosion Resistance for Long-Term Reliability

Corrosion resistance is a defining characteristic of the Bundy Tube. Its surface can be galvanized or coated with anti-corrosion materials, such as PVF or aluminum-rich coatings, ensuring long-term reliability in harsh environments. This protection prevents material degradation, extending the lifespan of refrigeration systems.

Several methods enhance the understanding of corrosion resistance and longevity:

- Accelerated corrosion testing combined with real-world exposure methods reveals material behavior under diverse conditions.

- Customized test protocols mimic specific deployment environments, improving relevance.

- Service history analysis provides reliable data reflecting actual conditions, aiding in predicting future performance.

- Field performance testing offers practical insights into material behavior over shorter periods, which can be extrapolated for long-term predictions.

These approaches highlight the Bundy Tube’s ability to maintain structural integrity and performance over time, making it an ideal choice for refrigeration applications.

Versatility in Complex System Designs

The Bundy Tube’s versatility allows it to adapt to complex system designs with ease. Its ability to be bent, welded, and shaped ensures compatibility with intricate refrigeration setups. This flexibility supports manufacturers in creating customized solutions tailored to specific requirements.

Quantitative analyses illustrate the pipe’s adaptability in handling complex designs:

- Nonlinear 3D finite element analyses (FEA) capture the assembly process and predict 3D configurations.

- Sophisticated 3D architectures emerge from 2D precursors, demonstrating design versatility.

- Maximum principal strains in 3D mesostructures remain below fracture thresholds, ensuring structural integrity.

- Design approaches, such as bonding sites in 2D precursors and spiral-shaped configurations, lead to unique 3D structures through tensile buckling.

These capabilities enable the Bundy Tube to meet the demands of modern refrigeration systems, where precision and adaptability are critical. Its ability to integrate seamlessly into complex designs underscores its value in industrial and commercial applications.

Enhancing System Efficiency and Reducing Costs

Superior Heat Transfer for Energy Efficiency

The Bundy Tube’s superior heat transfer capabilities significantly enhance energy efficiency in refrigeration systems. Its advanced design ensures optimal thermal conductivity, allowing for faster and more effective heat exchange. Comparative performance tests confirm this advantage:

| Configuration | JF Factor Comparison | η Variation (%) | Heat Transfer Rate Comparison |

|---|---|---|---|

| CPHEdiag. | Higher than CPHEvert. | 4–11.8% greater | Larger than CPHEvert. |

| CPHEvert. | Lower than CPHEdiag. | - | Smaller than CPHEdiag. |

This data highlights the Bundy Tube’s ability to outperform alternative configurations, ensuring reduced energy consumption. By minimizing energy losses, refrigeration systems equipped with these pipes achieve lower operational costs and improved environmental sustainability.

Reduced Maintenance Costs Due to Durability

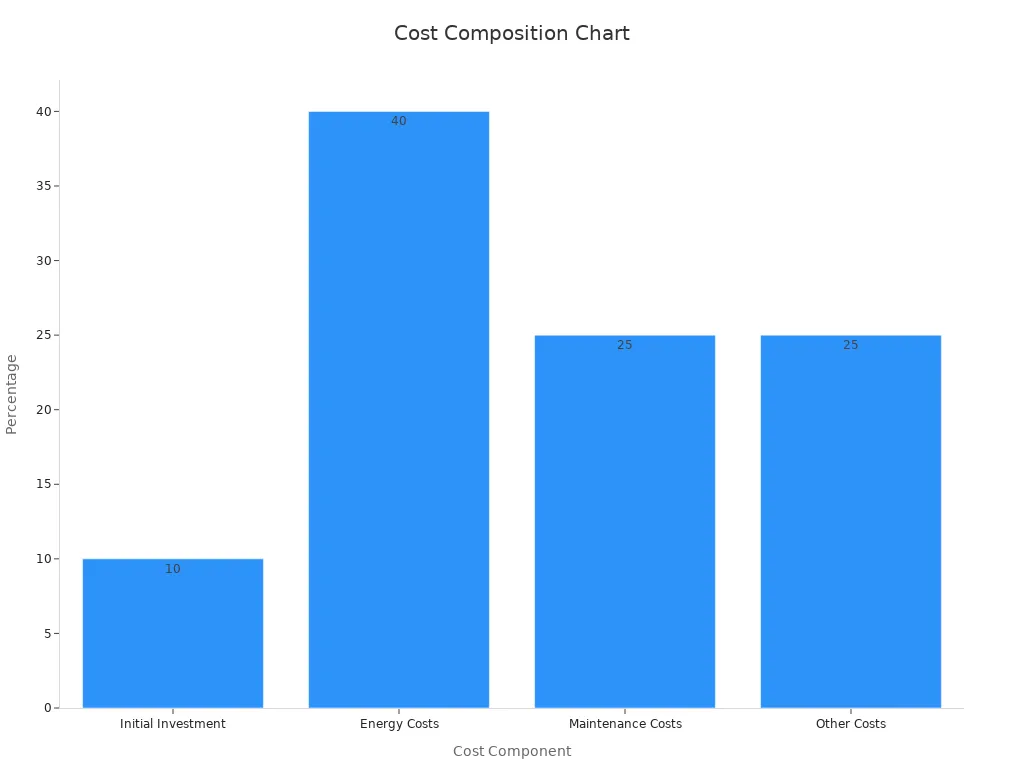

The Bundy Tube’s durability directly contributes to reduced maintenance costs. Its robust double-layer structure resists wear and tear, minimizing the need for frequent repairs or replacements. Maintenance cost analyses reveal the financial benefits of this durability:

| Cost Component | Percentage of Total Cost |

|---|---|

| Initial Investment | 10% |

| Energy Costs | 40% |

| Maintenance Costs | 25% |

| Other Costs | 25% |

This breakdown emphasizes how durable components like the Bundy Tube can significantly lower maintenance expenses, allowing businesses to allocate resources more efficiently.

Long-Term Savings from Extended Lifespan

The Bundy Tube’s extended lifespan offers substantial long-term savings for refrigeration systems. Studies comparing hydronic and VRF systems demonstrate the financial impact of longevity. Hydronic systems, with a life expectancy of 25 years, outlast VRF systems by a decade. This extended lifespan reduces the frequency of replacements and associated costs.

Additionally, the Bundy Tube’s corrosion-resistant coatings and clean internal surface further enhance its longevity. These features ensure consistent performance over time, reducing the likelihood of system failures. By investing in durable and long-lasting components, businesses can achieve significant cost savings while maintaining reliable refrigeration operations.

Why Bundy Tube Copper Pipes Outperform Alternatives

Comparison with Other Materials in Refrigeration Systems

Bundy tube copper pipes consistently outperform alternative materials in refrigeration systems due to their superior thermal conductivity, durability, and energy efficiency. Comparative data highlights their advantages:

| Metric | Bundy Tube Copper Pipes | Alternative Materials |

|---|---|---|

| Heat Transfer Coefficient | 50% higher | Lower |

| Energy Consumption | Reduced | Higher |

| Durability | High | Variable |

These pipes achieve a 50% higher heat transfer coefficient compared to traditional plate condensers, ensuring faster and more efficient cooling. Their design optimizes airflow, reducing energy consumption and operational costs. Unlike steel or aluminum, Bundy tube copper pipes maintain consistent performance over time, making them a reliable choice for refrigeration applications.

Environmental Benefits of Using Copper Pipes

Copper pipes offer significant environmental benefits, making them a sustainable option for refrigeration systems. Their longevity reduces the need for frequent replacements, minimizing resource consumption. Additionally, copper is fully recyclable, ensuring minimal waste during demolition or system upgrades.

The material’s energy efficiency further enhances its environmental profile. By reducing energy consumption in refrigeration systems, copper pipes contribute to lower greenhouse gas emissions. Their ability to improve indoor air quality also aligns with modern sustainability goals. These attributes make copper an environmentally responsible choice for industries seeking to balance performance with eco-friendliness.

Proven Track Record in Industrial and Commercial Applications

Copper pipes have a long history of success in industrial and commercial refrigeration systems. Their exceptional thermal conductivity and corrosion resistance make them indispensable in demanding environments. Studies show that copper tubing can last 10–25 years, with proper maintenance extending this lifespan even further.

Unlike materials like plastic or aluminum, copper withstands significant temperature variations without cracking or leaking. This durability ensures consistent performance, even in harsh conditions. Industries ranging from food storage to pharmaceutical manufacturing rely on copper pipes for their reliability and efficiency. Their proven track record underscores their value as a trusted solution for refrigeration needs.

Rolling Bundy tube copper pipes from Taojun HVAC deliver unmatched precision, durability, and efficiency, making them the preferred choice for refrigeration systems. Their innovative double-layer structure enhances strength, while the clean internal surface ensures optimal refrigerant flow. These features contribute to long-term cost savings and reliable performance.

A longitudinal study revealed that startups with a consistent mentoring strategy had a 30% higher success rate compared to those without, highlighting the importance of sustained support in achieving long-term performance benefits.

Comprehensive industry reports validate these claims, emphasizing the growing demand for energy-efficient and eco-friendly refrigeration solutions:

| Aspect | Details |

|---|---|

| Focus | Precision chillers and air conditioning systems |

| Key Factors | Energy efficiency, regulatory standards, eco-friendly refrigerants |

| Market Trends | Increasing demand for advanced features and optimized performance |

By choosing Bundy tube copper pipes, businesses can enhance system efficiency, reduce maintenance costs, and achieve sustainable refrigeration solutions.

FAQ

What makes Bundy Tube copper pipes suitable for refrigeration systems?

Bundy Tube copper pipes excel in refrigeration due to their double-layer structure, precision rolling technology, and corrosion resistance. These features ensure durability, accurate dimensions, and efficient refrigerant flow, making them ideal for demanding cooling applications.

How does the double-layer structure enhance pipe performance?

The double-layer structure increases strength and durability. It allows the pipe to withstand high-pressure environments and resist mechanical stress, ensuring long-term reliability in refrigeration systems.

Are Bundy Tube copper pipes environmentally friendly?

Yes, Bundy Tube copper pipes are eco-friendly. Copper is fully recyclable, and its energy-efficient properties reduce greenhouse gas emissions. These attributes make it a sustainable choice for refrigeration applications.

Can Bundy Tube copper pipes be customized for specific designs?

Bundy Tube copper pipes offer excellent versatility. They can be bent, welded, and shaped to fit complex refrigeration system designs, enabling manufacturers to create tailored solutions for unique requirements.

How do Bundy Tube copper pipes reduce maintenance costs?

Their robust construction and corrosion-resistant coatings minimize wear and tear. This durability reduces the need for frequent repairs or replacements, leading to lower maintenance expenses over time.