Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

Why Liquid Line Filter Driers Matter

HVAC and refrigeration systems rely on precision to operate effectively. Moisture and contaminants can disrupt this balance, leading to inefficiencies or even system breakdowns. A liquid line Filter Drier plays a critical role in preventing these issues. By removing harmful particles and excess moisture, it safeguards components and ensures smooth, long-term operation.

Key Takeaways

- Liquid line filter driers help remove water and dirt from refrigerants. This keeps HVAC and refrigeration systems working well.

- Checking and replacing filter driers on time avoids expensive fixes. It also helps the equipment last longer.

- Picking the correct filter drier for your system is important. It ensures the system works properly and stays dependable.

What is a Liquid Line Filter Drier?

Definition and Purpose

A liquid line filter drier is a critical component in HVAC and refrigeration systems. It is designed to remove moisture, acid, and solid contaminants from the refrigerant, ensuring the system operates efficiently and reliably. By preventing these impurities from circulating, the filter drier protects sensitive components like compressors and expansion valves from damage. This not only enhances system performance but also reduces the risk of costly repairs.

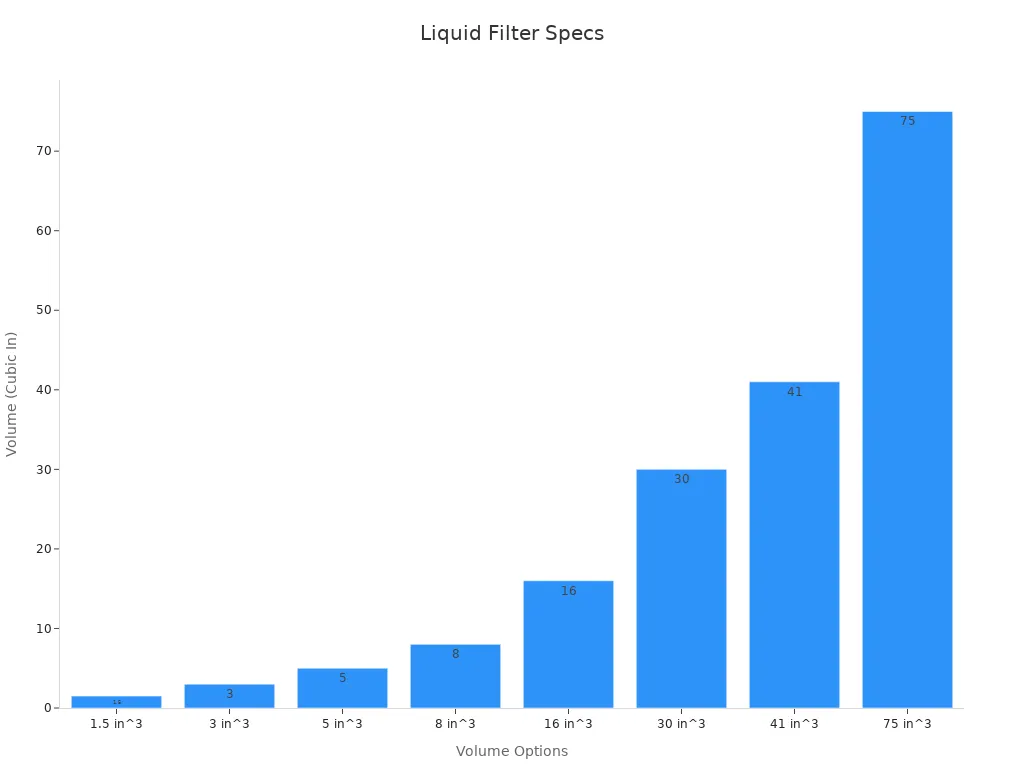

The technical specifications of a liquid line filter drier vary depending on the application. Key parameters include desiccant volume, connection sizes, and maximum working pressure. The table below highlights some common specifications:

| Specification Type | Details |

|---|---|

| Desiccant Volume | 1.5, 3, 5, 8, 16, 30, 41 & 75 Cubic Inch |

| Connection Sizes | 1/4″ to 1-1/8” (hermetic), 5/8” to 3-3/8” (semi hermetic) |

| Maximum Working Pressure | 653 psig (45 bar) |

| UL Listing | Yes, UL File number SA33181-20140331 |

These specifications ensure compatibility with a wide range of systems, making the liquid line filter drier a versatile solution for maintaining refrigerant purity.

Applications in HVAC and Refrigeration Systems

Liquid line filter driers are widely used across various sectors, including residential, commercial, and industrial applications. In HVAC systems, they play a vital role in maintaining optimal cooling and heating performance by preventing moisture and debris from clogging the system. In refrigeration systems, they ensure the refrigerant remains free of contaminants, which is essential for preserving food and other perishable items.

The market share of liquid line filter driers reflects their importance in different industries. The table below provides an overview of their application sectors:

| Application Sector | Market Share (%) | Growth Rate |

|---|---|---|

| Automobile | 45% | N/A |

| Mechanical | 25% | Fastest Growing in HVAC Systems |

The automobile sector accounts for the largest share, as air conditioning systems in vehicles rely heavily on liquid line filter driers. Meanwhile, the mechanical sector, particularly HVAC systems, is experiencing rapid growth due to increasing demand for energy-efficient cooling and heating solutions.

By addressing the unique needs of these applications, liquid line filter driers contribute to the reliability and longevity of HVAC and refrigeration systems.

How Does a Liquid Line Filter Drier Work?

Moisture Absorption Process

A liquid line filter drier operates by absorbing moisture from the refrigerant, ensuring the system remains dry and efficient. Moisture in refrigerants can lead to the formation of acids, which corrode internal components and reduce system performance. The filter drier uses desiccant granules, typically made of Molecular Sieves or activated alumina, to trap and retain moisture. These granules are strategically packed within the filter housing to maximize contact with the refrigerant.

Laboratory experiments have demonstrated the effectiveness of this moisture absorption process under varying conditions. The table below highlights key findings:

| Experimental Condition | Result | Observation |

|---|---|---|

| Gas flow rate: 600 L/min | ~90 min to reach equilibrium | Moisture content reduced to ~1.5 wt% |

| Gas flow rate: 850 L/min | ~60 min drying time | Faster drying rate observed |

| Moisture content change | 33 wt% to 10 wt% | Granules shrank, losing 26% of mass |

| Low moisture levels (5-1%) | Surface dried granules | Significant fines generated, increasing pressure drop across filters |

These results highlight the importance of selecting a filter drier with the appropriate desiccant volume and flow rate compatibility. Proper sizing ensures efficient moisture removal without compromising system pressure.

Contaminant Filtration Mechanism

In addition to moisture absorption, a liquid line filter drier plays a vital role in filtering out solid contaminants. These contaminants, such as dirt, metal particles, and sludge, can clog critical components like expansion valves and capillary tubes. The filter drier uses a fine mesh or porous material to trap these particles, preventing them from circulating through the system.

Performance tests have measured the filtration efficiency of liquid line filter driers under controlled conditions. Key insights include:

- The filtration efficiency and dirt retention test evaluates how much contamination a filter drier can remove while maintaining an acceptable pressure drop.

- ASHRAE Standard 63.2-2024 provides a benchmark for assessing filtration capabilities. It uses controlled-particle-size contaminants to ensure consistent comparisons across different filter driers.

These tests emphasize the importance of high-quality filter driers in maintaining system cleanliness and reliability. By effectively removing contaminants, the filter drier reduces wear on components and minimizes the risk of system failures.

Benefits of Using a Liquid Line Filter Drier

Enhanced System Efficiency

Liquid line filter driers improve system efficiency by maintaining refrigerant purity. Contaminants like moisture and particles can disrupt the flow of refrigerant, leading to reduced cooling or heating performance. By removing these impurities, the filter drier ensures smooth refrigerant circulation and optimal heat exchange. This process minimizes energy consumption and enhances the overall efficiency of HVAC and refrigeration systems.

Tip: Regular maintenance of the filter drier ensures consistent performance and prevents energy wastage.

Prolonged Equipment Lifespan

Installing a liquid line filter drier significantly extends the lifespan of HVAC and refrigeration equipment. Contaminants such as acids and moisture can corrode internal components, leading to premature wear and tear. The filter drier prevents these issues by keeping the refrigerant clean before it enters sensitive parts like expansion devices. This protection reduces the frequency of repairs and ensures long-term reliability.

| Impact of Filter Driers on Equipment Longevity | Details |

|---|---|

| Contaminant Removal | Prevents corrosion and freeze-ups |

| Enhanced Performance | Reduces strain on critical components |

| Lower Maintenance Costs | Minimizes repair frequency |

Prevention of System Failures

Liquid line filter driers play a crucial role in preventing system failures. Moisture and debris can cause blockages in expansion valves or capillary tubes, leading to operational disruptions. By filtering out these contaminants, the filter drier ensures uninterrupted system functionality. This proactive approach reduces the risk of costly downtime and protects the integrity of HVAC and refrigeration systems.

Note: High-quality filter driers, like those offered by Ningbo Taojun Refrigeration Equipment Co., Ltd., provide reliable protection against system failures.

When to Replace a Liquid Line Filter Drier

Signs of Reduced Performance

Over time, a liquid line filter drier may lose its effectiveness, leading to noticeable performance issues in HVAC and refrigeration systems. One of the most common indicators is a higher-than-normal compressor discharge temperature, which can signal restricted refrigerant flow. Other signs include low evaporator pressure, high superheats, and low condensing pressure. These conditions often result in reduced cooling or heating efficiency, impacting overall system performance.

Technicians can use diagnostic measurements to identify these issues. The table below outlines key values that may indicate reduced performance:

| Measured Values | Values |

|---|---|

| Compressor discharge temperature | 215°F |

| Condenser outlet temperature | 70°F |

| Evaporator outlet temperature | 30°F |

| Compressor in temperature | 60°F |

| Ambient temperature | 70°F |

| Box temperature | 30°F |

| Compressor volts | 230 |

| Compressor amps | Low |

| Low-side (evaporating) pressure | 1.8 psig (-10°F) |

| High-side (condensing) pressure | 95 psig (85°F) |

Calculated values, such as a condenser split of 15°F and an evaporator superheat of 40°F, further highlight potential inefficiencies. Regular monitoring of these parameters can help detect early signs of reduced performance, ensuring timely replacement of the filter drier.

Indicators of Wear or Blockage

Physical wear or blockages in a liquid line filter drier can also signal the need for replacement. Common symptoms include local cold spots or frost forming after the restriction point, which indicates trapped moisture or debris. Low amp draw and short cycling of the low-pressure control (LPC) are additional warning signs. These issues can lead to uneven refrigerant flow, causing strain on the system and increasing the risk of component failure.

Technicians should also inspect for dirt accumulation or corrosion on the filter drier's exterior. A clogged filter can result in low condenser splits and normal-to-high condenser subcooling, further reducing system efficiency. Replacing the filter drier at the first sign of wear or blockage prevents more severe damage and ensures the system continues to operate reliably.

Tip: Regular maintenance and timely diagnostics are essential for identifying wear or blockages early, minimizing costly repairs.

Choosing the Right Liquid Line Filter Drier

Factors to Consider

Selecting the right liquid line filter drier requires careful evaluation of several factors. The desiccant type plays a crucial role in moisture absorption. Molecular sieves are ideal for systems requiring high moisture removal, while activated alumina works well for acid removal. The size of the filter drier must match the system's refrigerant capacity to ensure optimal performance.

Pressure rating is another critical consideration. Systems operating at higher pressures demand filter driers with robust construction to withstand the load. Connection types and sizes should align with the system's piping to avoid installation challenges.

Tip: Always consult the manufacturer's specifications to ensure the filter drier meets the system's operational requirements.

Importance of System Compatibility

System compatibility is essential for achieving efficient and reliable operation. A liquid line filter drier designed for one refrigerant type may not perform effectively with another. For instance, systems using R-410A refrigerant require filter driers with specific desiccant blends to handle its unique properties.

Improper compatibility can lead to restricted refrigerant flow, increased energy consumption, and potential system failures. Technicians should verify that the filter drier matches the system's refrigerant type, pressure levels, and connection standards. This ensures seamless integration and long-term reliability.

Note: High-quality filter driers, like those from Ningbo Taojun Refrigeration Equipment Co., Ltd., offer a range of options tailored to diverse system needs.

Liquid line filter driers play a vital role in preserving the efficiency and reliability of HVAC and refrigeration systems. Regular inspections and timely replacements prevent costly breakdowns and extend equipment lifespan. Choosing a filter drier that aligns with system requirements ensures peak performance and long-term operational stability.

FAQ

What happens if a liquid line filter drier is not replaced on time?

Failure to replace it can lead to moisture buildup, acid formation, and clogged components, causing reduced efficiency and potential system failure.

Can a liquid line filter drier be reused after removal?

No, reusing a removed filter drier is not recommended. Once exposed, its desiccant loses effectiveness, compromising its ability to absorb moisture and contaminants.

How do I choose the correct size for my system?

Match the filter drier's capacity to your system's refrigerant volume and pressure requirements. Consult the manufacturer's specifications for accurate sizing.