Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

What Is the Role of Bundy Tube Wire Tube Condensers in Freezers and Coolers

Bundy Tube Wire tube condensers play a vital role in the cooling process of freezers and coolers. They efficiently transfer heat from inside the appliance to the surrounding air. Their specialized design allows for rapid heat removal, which helps food stay fresh and safe. Many manufacturers choose this type of condenser for its reliability and strong performance.

Key Takeaways

- Bundy Tube Wire tube condensers efficiently remove heat in freezers and coolers, helping keep food fresh and safe.

- Their unique wire and tube design increases surface area, boosting heat transfer and energy efficiency by up to 32.9%.

- These condensers are durable, easy to maintain, and cost-effective, reducing energy use and lowering appliance costs.

- They fit well in both home and commercial refrigeration systems, offering reliable cooling and quick temperature control.

- Manufacturers prefer them for their strong performance, simple production, and compatibility with eco-friendly refrigerants.

How Bundy Tube Wire Tube Condensers Work in Freezers and Coolers

Heat Exchange Mechanism

A Bundy Tube Wire tube condenser removes heat from the refrigerant as it cycles through the refrigeration system. The process begins when the hot, high-pressure refrigerant gas enters the condenser coils. As the gas flows through the Bundy tubes, it releases heat to the surrounding air. The wire structure attached to the tubes increases the surface area, which speeds up heat transfer. This rapid heat removal causes the refrigerant to condense into a liquid, ready for the next stage of cooling.

Experimental data shows that Bundy Tube Wire tube condensers deliver a 32.9% increase in heat transfer efficiencycompared to traditional copper tube condensers. The coefficient of performance (COP) rises by 17%, and evaporator capacity increases by 24%. These improvements mean that freezers and coolers can maintain low temperatures more efficiently, using less energy.

- Researchers have validated the heat exchange mechanism in several ways:

- They measured heat transfer coefficients for refrigerants like R134a and R290.

- Bundy tube-based condensers reduced compressor power consumption by 0.3 to 0.5 Amps.

- Modifications in tube geometry, such as elliptical shapes, further improved heat transfer rates and reduced pressure drop.

- Design optimizations and material choices, such as copper or aluminum, also influenced efficiency.

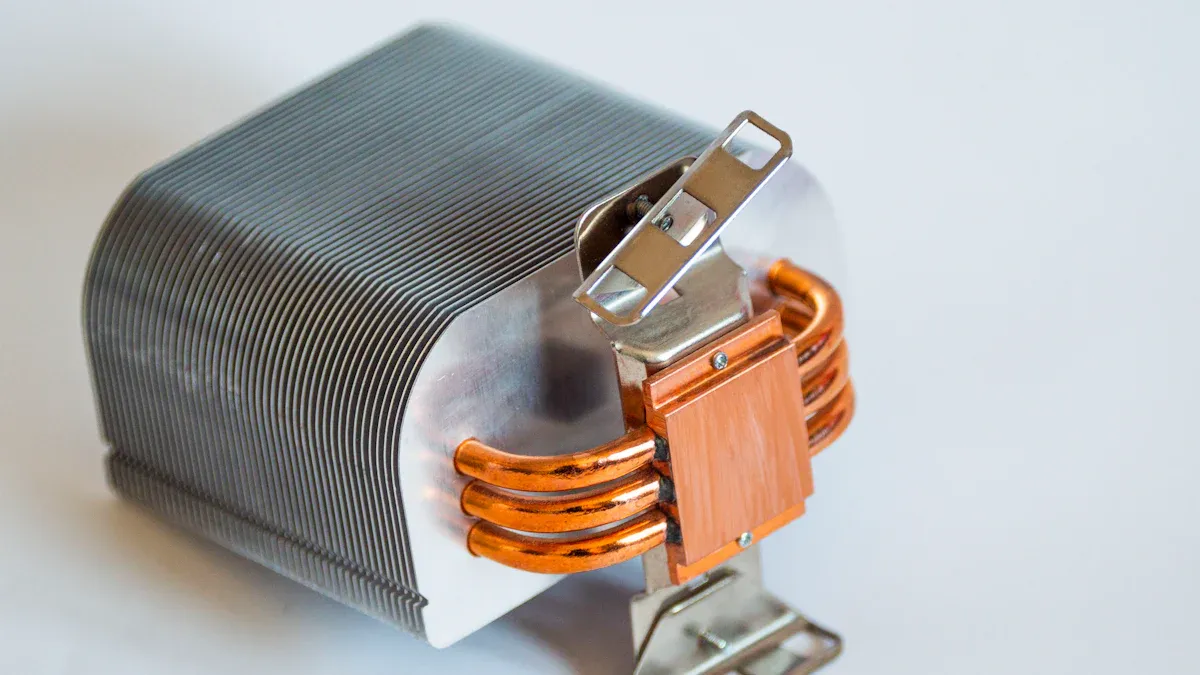

Structure and Materials of Bundy Tube Wire Tube Condensers

The Bundy Tube Wire tube condenser uses a unique construction. It consists of a steel or copper tube, often double-walled for added strength and corrosion resistance. Thin wires are welded or wrapped around the tube, forming a grid-like structure. This design increases the contact area between the tube and the air, which enhances heat dissipation.

Manufacturers select materials based on their thermal conductivity and durability. Copper and aluminum are common choices because they transfer heat quickly and resist corrosion. The double-walled tube design provides extra protection against leaks and extends the lifespan of the condenser. The wire grid not only improves heat transfer but also adds structural support, making the condenser more robust.

Note: The combination of high-quality materials and innovative design ensures that Bundy Tube Wire tube condensers deliver reliable performance in demanding refrigeration environments.

Integration with Refrigeration Systems

Bundy Tube Wire tube condensers integrate seamlessly into modern refrigeration systems. Engineers design these condensers to fit compactly within the appliance, often mounting them on the back or underneath the unit. The condenser connects directly to the compressor and evaporator, forming a closed-loop system that circulates refrigerant efficiently.

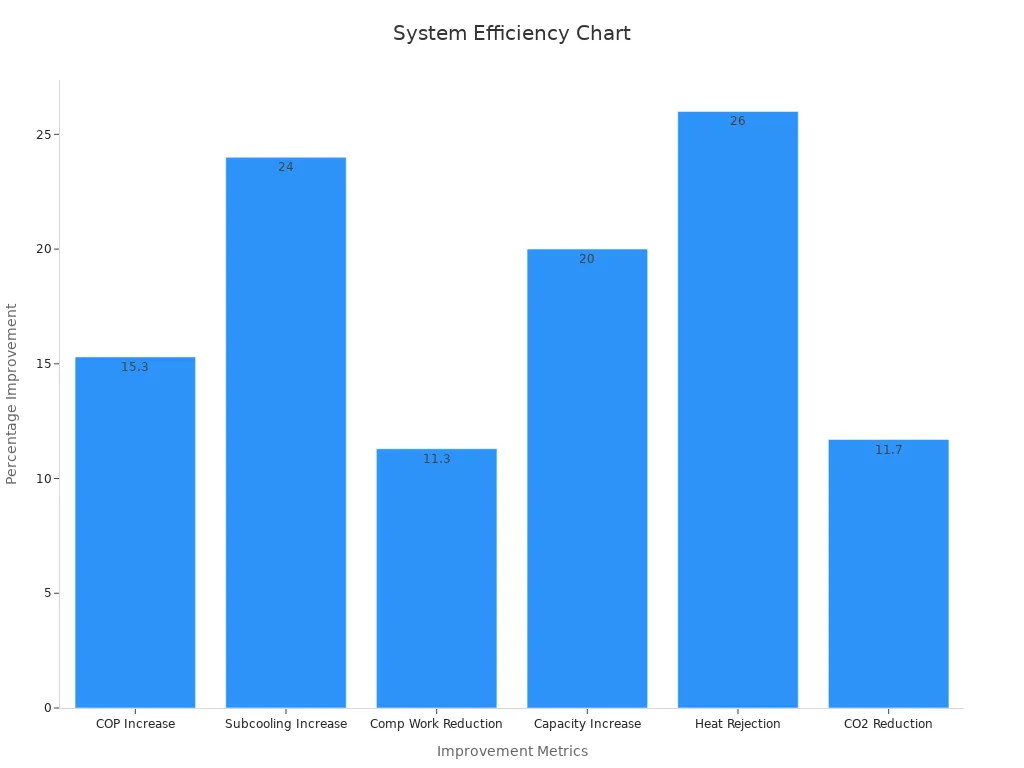

Integration tests reveal significant performance gains when using Bundy Tube Wire tube condensers. The following table summarizes key improvements compared to classical condenser technologies:

| Metric | Improvement / Change | Explanation |

|---|---|---|

| Coefficient of Performance (COP) | Increase by up to 15.3% (range 12.7% to 29%) | Enhanced energy efficiency compared to traditional condensers. |

| Sub-cooling Improvement | Up to 24% | Maintains lower temperatures with less energy consumption. |

| Compressor Workload Reduction | Up to 11.3% | Reduces power consumption by lowering compressor effort. |

| Capacity Increase | Up to 20% | More cooling power delivered within the same physical footprint. |

| Condensing Temperature Drop | Approximately 2 °C | Lower operating temperatures improve heat rejection efficiency. |

| Heat Rejection Rate Increase | Around 26% | Faster heat removal enhances overall system performance. |

| CO2 Emissions Reduction | Approximately 11.7% | Lower greenhouse gas emissions benefit the environment. |

| Temperature Stability | Rapid stabilization with settling times as low as 17.66 seconds and minimal overshoot (6.06%) | Ensures consistent internal temperatures critical for food preservation and system reliability. |

Bundy Tube Wire tube condensers help refrigeration systems achieve rapid temperature stabilization and consistent cooling. These benefits make them a preferred choice for both residential and commercial freezers and coolers.

Why Bundy Tube Wire Tube Condensers Are Used in Refrigeration

Suitability for Freezer and Cooler Applications

Bundy Tube Wire tube condensers meet the demanding requirements of modern refrigeration. Their design supports efficient heat removal, which is essential for maintaining low temperatures in freezers and coolers. These condensers work well in both residential and commercial settings. Manufacturers rely on them for their ability to deliver consistent performance in a wide range of environments.

Industry data highlights several reasons for their widespread adoption:

- High heat transfer efficiency ensures rapid cooling and stable internal temperatures.

- Energy-saving benefits help reduce operational costs for both homeowners and businesses.

- Compatibility with various refrigerants, including eco-friendly options, supports compliance with environmental regulations.

- Versatility allows use in refrigerators, freezers, display cabinets, and even refrigerated transportation units.

- Integration with smart technologies enables real-time monitoring and energy optimization.

These features make Bundy Tube Wire tube condensers a preferred choice for applications where reliability and efficiency matter most.

Manufacturing and Design Advantages

Manufacturers value Bundy Tube Wire tube condensers for their straightforward yet effective construction. The design uses steel or copper tubes with spot-welded wires, creating a robust structure that maximizes heat transfer. Experimental testing of multiple condenser samples shows that adjusting the spacing between wires and tubes significantly improves performance. The tube and wire diameters have less impact, contributing less than 4% to the overall heat transfer rate. This finding allows engineers to focus on optimizing the pitch, which leads to better results without increasing material costs.

Key manufacturing and design advantages include:

- Simple assembly process reduces production time and labor requirements.

- Use of carbon steel and spot-welded wires lowers material costs while maintaining durability.

- Flexible design accommodates different sizes and shapes, making it easy to customize for specific appliances.

- Proven heat transfer performance, with heat duties ranging from 35 W to 175 W depending on geometry and conditions.

A semi-empirical heat transfer correlation developed from these experiments predicts air-side heat transfer coefficients within a 10% margin of error. This validation gives manufacturers confidence in the reliability and efficiency of the design.

Cost-Effectiveness and Production Efficiency

Bundy Tube Wire tube condensers offer significant cost advantages over competing technologies. The combination of affordable materials and efficient manufacturing processes makes them one of the most economical heat exchangers available. Manufacturers can produce these condensers at scale, meeting the growing demand for energy-efficient refrigeration solutions worldwide.

Several factors contribute to their cost-effectiveness:

- Lower material costs due to the use of carbon steel and optimized wire arrangements.

- Streamlined production methods, such as spot welding, increase output and reduce waste.

- Customizable designs allow manufacturers to meet diverse industry needs without major retooling.

- Reduced operational costs for end users, thanks to improved energy efficiency and durability.

The global market for wire tube condensers continues to expand, driven by trends in industrialization, urbanization, and sustainability. Manufacturers respond by increasing production capacity and offering tailored solutions for different applications. These efforts ensure that Bundy Tube Wire tube condensers remain a top choice for both new installations and replacement projects.

Key Benefits of Bundy Tube Wire Tube Condensers

Energy Efficiency and Performance

Bundy Tube Wire tube condensers deliver strong energy efficiency in refrigeration systems. Their open wire design increases the surface area for heat exchange, which helps the system cool faster and use less electricity. Many operational studies show that these condensers can improve heat transfer efficiency by up to 19%. This improvement means freezers and coolers can keep food at safe temperatures while lowering energy bills. The design also supports stable temperature control, which is important for food safety and appliance reliability. By reducing the workload on the compressor, the system runs more quietly and lasts longer.

Durability and Longevity

Manufacturers build Bundy Tube Wire tube condensers with robust materials like copper or steel. The double-walled tube construction resists corrosion and prevents leaks, even after years of use. The wire grid adds extra strength, making the condenser less likely to bend or break during operation or maintenance. Regular care and the use of high-quality materials help extend the lifespan of the entire refrigeration system. Many users report that appliances with these condensers continue to perform well for many years, even in demanding environments.

Maintenance and Reliability

Technicians find Bundy Tube Wire tube condensers easy to maintain. The open design allows for quick visual inspections and simple cleaning with basic tools. Maintenance logs and operational studies confirm that regular care supports long-term reliability. The following table outlines a typical maintenance schedule:

| Maintenance Frequency | Key Maintenance Activities and Impact |

|---|---|

| Daily | Monitor system performance and check for obvious issues to ensure early detection of problems. |

| Monthly | Clean or replace air filters, inspect belts and pulleys, clean drain pans and condensate lines, test electrical connections, and monitor refrigerant levels to maintain efficiency. |

| Quarterly | Perform thorough cleaning of condenser and evaporator coils, inspect heating and cooling components, test safety controls, and check refrigerant pressure to prevent performance degradation. |

| Annual | Conduct full system performance evaluation, deep cleaning including ductwork, calibrate controls and Thermostats, and inspect electrical and safety systems to ensure long-term reliability. |

| Seasonal (Spring) | Clean condenser coils, check refrigerant levels, and clear debris from outdoor units to prepare for peak operation. |

| Seasonal (Summer) | Monitor cooling performance, clean condenser coils as needed, and check refrigerant pressure to maintain optimal operation during high demand. |

- Quick inspections help spot dust or blockages early.

- Cleaning requires only soft brushes or vacuums.

- The design reduces the risk of accidental damage during care.

- Smart monitoring systems can alert users to potential issues before they become serious.

These features make the Bundy Tube Wire tube condenser a reliable and low-maintenance choice for both residential and commercial refrigeration.

Affordability Compared to Alternatives

Bundy Tube Wire tube condensers offer a clear cost advantage over many other condenser types. Manufacturers often choose them because they combine high performance with low production costs. This affordability makes them a popular choice for both residential and commercial refrigeration units.

Several factors contribute to their cost-effectiveness:

- Material Savings: Bundy Tube Wire tube condensers use carbon steel or copper, which are less expensive than the all-copper or aluminum materials found in some other condenser designs.

- Efficient Manufacturing: The simple structure allows for automated production lines. Spot welding wires to tubes speeds up assembly and reduces labor costs.

- Lower Maintenance Costs: The robust design means fewer repairs and replacements over the lifespan of the appliance.

Tip: Choosing Bundy Tube Wire tube condensers can help manufacturers keep appliance prices competitive without sacrificing quality.

The following table compares the typical cost factors for Bundy Tube Wire tube condensers and two common alternatives:

| Feature | Bundy Tube Wire Tube | Plate Condenser | Finned Condenser |

|---|---|---|---|

| Material Cost | Low | Medium | High |

| Manufacturing Complexity | Simple | Moderate | Complex |

| Maintenance Needs | Low | Medium | High |

| Customization | High | Medium | Low |

| Typical Lifespan | Long | Medium | Medium |

Manufacturers who use Bundy Tube Wire tube condensers can scale up production quickly. They can also offer a wide range of product sizes without major changes to their processes. End users benefit from lower appliance prices and reduced energy bills over time.

Bundy Tube Wire Tube Condenser vs. Other Condenser Types

Comparison with Plate Condensers

Plate condensers use flat metal plates stacked together. Refrigerant flows through channels between the plates. This design creates a compact unit with a large surface area for heat exchange. Many engineers choose plate condensers for applications where space is limited. However, plate condensers often require higher manufacturing precision. Cleaning can be more difficult because of the narrow channels.

Bundy Tube Wire tube condensers use tubes with wires attached to increase surface area. This structure allows for easy cleaning and inspection. Technicians can spot dust or debris quickly. The open design also helps air flow freely around the tubes, which improves cooling performance.

Note: Plate condensers work well in some specialized systems, but Bundy Tube Wire tube condensers offer easier maintenance and strong durability for most freezers and coolers.

Comparison with Finned Condensers

Finned condensers use metal fins attached to tubes. The fins increase the surface area for heat transfer. Many commercial air conditioning systems use finned condensers. These units can handle high heat loads and work well in forced-air environments.

Bundy Tube Wire tube condensers provide similar benefits by increasing surface area with wires instead of fins. The wire structure resists clogging from dust and dirt. Maintenance teams find it easier to clean and service these condensers. Finned condensers may require more frequent cleaning to maintain efficiency.

| Feature | Bundy Tube Wire Tube | Plate Condenser | Finned Condenser |

|---|---|---|---|

| Cleaning Ease | High | Low | Medium |

| Air Flow | Excellent | Good | Good |

| Maintenance Frequency | Low | Medium | High |

| Space Efficiency | Good | Excellent | Good |

Unique Features and Limitations

Bundy Tube Wire tube condensers stand out for their open structure and robust materials. The design supports rapid heat transfer and easy maintenance. Many manufacturers select this type for its balance of cost, performance, and reliability.

- Open wire design allows for quick inspections.

- Double-walled tubes resist corrosion and leaks.

- Flexible sizing fits many appliance types.

Technicians recommend Bundy Tube Wire tube condensers for freezers and coolers that need reliable, long-term performance.

Applications and Suitability of Bundy Tube Wire Tube Condensers

Residential Freezers and Coolers

Homeowners rely on freezers and coolers to keep food fresh and safe. Many domestic appliances use Bundy Tube Wire tube condensers because these units fit well in compact spaces. The design allows for efficient heat removal, which helps maintain steady temperatures inside the appliance. Manufacturers can select from a range of tube and wire diameters, making it easy to match the condenser to different refrigerator sizes. The open structure also supports easy cleaning, which appeals to families who want low-maintenance solutions.

Note: Bundy Tube Wire tube condensers work quietly and efficiently, making them ideal for kitchens and utility rooms.

Commercial Refrigeration Units

Supermarkets, restaurants, and convenience stores depend on reliable refrigeration. Commercial units often require higher cooling capacity and robust performance. Bundy Tube Wire tube condensers meet these demands by offering advanced geometry that maximizes airflow and heat transfer. Companies can customize the tube and wire pitch to suit large-capacity systems. This flexibility ensures that even high-performance dynamic condensers deliver consistent results in busy environments. Technicians appreciate the durability and straightforward maintenance, which reduces downtime and keeps food products safe.

Optimal Use Cases

Bundy Tube Wire tube condensers serve a broad range of applications. Market analysis shows that these condensers perform well in both static and dynamic systems. Their suitability extends from small domestic fridges to large commercial display cabinets. The ability to customize each unit means manufacturers can address unique customer requirements.

Common use cases include:

- Household refrigerators and freezers

- Supermarket display cases

- Beverage coolers

- Medical and laboratory refrigeration

- Refrigerated transport vehicles

A table summarizing typical applications:

| Application Type | Key Requirements | Bundy Tube Wire Tube Condenser Suitability |

|---|---|---|

| Home Refrigerators | Quiet, compact, efficient | Excellent |

| Commercial Freezers | High capacity, durable | Excellent |

| Display Cabinets | Consistent cooling | Excellent |

| Medical/Lab Units | Precise temperature | Very Good |

Manufacturers value the adaptability and proven performance of these condensers across many industries.

Bundy Tube Wire tube condensers support reliable cooling in both home and commercial appliances. Their design balances performance, durability, and cost. Many manufacturers choose this technology for its proven results. Users benefit from steady temperatures and lower energy bills.

Understanding the role of a Bundy Tube Wire tube condenser helps buyers and engineers select the best refrigeration solutions for their needs.

FAQ

What is a Bundy Tube Wire tube condenser?

A Bundy Tube Wire tube condenser uses steel or copper tubes with wires attached. This design increases surface area for heat transfer. Manufacturers use it in freezers and coolers to remove heat efficiently.

How often should technicians clean Bundy Tube Wire tube condensers?

Technicians should inspect and clean these condensers every three months. Regular cleaning prevents dust buildup and keeps the system running efficiently.

Are Bundy Tube Wire tube condensers compatible with eco-friendly refrigerants?

Yes. These condensers work with many refrigerants, including eco-friendly options like R134a and R290. This compatibility supports environmental regulations and sustainability goals.

Why do manufacturers prefer Bundy Tube Wire tube condensers?

Manufacturers value these condensers for their cost-effectiveness, durability, and easy maintenance. The design allows for quick production and reliable performance in various refrigeration systems.