Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

What Happens Inside the Condenser of a Refrigeration System

The condenser in a refrigeration system plays a crucial role in transforming hot, high-pressure refrigerant vapor into liquid. During this process, the refrigerant releases heat to the surrounding air through three main stages: desuperheating, condensing, and subcooling. Studies using advanced data analysis methods, such as multilayer perceptron and decision trees, show that condenser temperature significantly affects system performance. Key performance metrics demonstrate that desuperheating can improve the coefficient of performance (COPh) by up to 6%, while interstage subcooling may boost it by as much as 23%.

Efficient heat removal in the condenser directly impacts energy consumption and overall cooling effectiveness.

| Parameter/Condition | Value / Effect |

|---|---|

| Maximum COPh improvement by desuperheating | Less than 6% |

| Maximum COPh improvement by subcooling | Up to 23% |

| COP_system | 2.83 |

| Annual CO₂ emission reduction | 8.71 tons |

Key Takeaways

- The condenser cools hot refrigerant vapor and turns it into liquid, which is essential for effective cooling.

- Desuperheating lowers the vapor temperature before condensation, improving heat transfer and system reliability.

- Condensation changes vapor to liquid by releasing heat, and this phase change is key to the refrigeration cycle.

- Subcooling cools the liquid refrigerant below its condensation point, boosting cooling power and system efficiency.

- Regular maintenance and monitoring of the condenser help prevent problems, save energy, and extend equipment life.

The Condenser in a Refrigeration System: Core Function

Heat Removal from Refrigerant

The condenser in a refrigeration system performs a vital role by removing heat from the refrigerant. When the compressor sends high-pressure, superheated vapor into the condenser, the process of heat rejection begins. The condenser must eliminate all the heat absorbed in the evaporator, as well as the heat generated by the compressor. This process ensures that the refrigerant can continue its cycle efficiently.

Design features such as fins, fans, and pumps help increase the rate of heat transfer. Air-cooled condensers use forced air and extended surfaces to boost heat removal, while water-cooled condensers rely on water’s superior heat transfer properties. Evaporative condensers combine both air and water to maximize cooling. Clean surfaces and proper airflow or water flow are essential for effective operation.

Proper maintenance of the condenser ensures maximum heat rejection and system reliability.

Researchers have used advanced simulations to show that two-phase refrigerant cooling provides better temperature reduction and thermal management than single-phase water cooling. These studies highlight the importance of phase change in enhancing heat transfer and demonstrate the significant cooling capacity of the condenser.

Key steps in the heat removal process:

- The condenser receives high-pressure, superheated vapor from the compressor.

- It removes sensible heat, lowering the vapor temperature to the saturation point.

- The vapor then loses latent heat and condenses into a liquid.

- Finally, the liquid refrigerant is further cooled below its saturation temperature.

Preparing Refrigerant for Expansion

After the refrigerant condenses into a liquid, the condenser prepares it for the next stage—expansion. This preparation is crucial for efficient cooling in the evaporator. The process involves subcooling, where the liquid refrigerant’s temperature drops below its condensation point. Subcooling prevents flash gas formation during expansion, which improves system performance.

| Component | Exergy Destruction Expression | Exergy Efficiency Expression |

|---|---|---|

| Expansion valve | Exdes_exp = Ex3 − Ex4 = mNRT0(s4,NR − s3,NR) | ηex_exp = Ex4 / Ex3 |

| Condenser | Exdes_con = Ex2 − Ex3 − Qc1 − T0/Tc = mNRT0(Tc h2,NR − h3,NR − T0 s2,NR − s3,NR) | ηex_con = 1 − Exdes_con / (Ex2 − Ex3) |

Studies show that using advanced refrigerants and optimized condenser designs can increase the coefficient of performance and exergy efficiency. These improvements lead to lower compressor discharge temperatures and better overall system efficiency. By ensuring the refrigerant is properly cooled and ready for expansion, the condenser supports reliable and effective refrigeration.

Desuperheating in the Condenser

Cooling the Superheated Vapor

Desuperheating marks the first stage inside the condenser. When the compressor sends superheated refrigerant vapor into the condenser, the vapor temperature is higher than its saturation point. The main goal of desuperheating is to cool this vapor down to the saturation temperature, preparing it for condensation.

Experimental studies confirm that as the superheated vapor flows through the condenser, its temperature drops. Researchers observed that when the tube wall temperature reaches the saturation point, condensation begins. During this process, the bulk mean temperature of the refrigerant decreases. For example, tests with refrigerants like CO₂ and R410A show that the vapor cools rapidly as it passes through the condenser tubes. The temperature reduction can range from 5 to 25 Kelvin, depending on the system and operating conditions.

Note: As the vapor cools, both superheated vapor and subcooled liquid can exist together in the condenser, creating a transition zone that is critical for efficient heat transfer.

Importance of Desuperheating

Desuperheating plays a vital role in the overall performance of a refrigeration system. By lowering the temperature of the refrigerant vapor before condensation, the system improves its heat transfer efficiency. This stage ensures that the refrigerant is ready for the next phase change, which is essential for reliable cooling.

The effectiveness of desuperheating can be measured by several key metrics:

| Metric | Observed Effect / Value | Description / Impact |

|---|---|---|

| Heat Transfer Coefficient | Increase up to 18% (low mass flux, high superheating) | Enhanced condensation kinetics and improved heat transfer efficiency. |

| Vapor Temperature Reduction | 5–25 K drop | Effective lowering of refrigerant temperature during desuperheating stage. |

| Vapor Superheat Range | 5–30 K | Range over which desuperheating effects were studied and confirmed. |

| Mass Flux Range | 15–41 kg/m²/s | Shows dependency of heat transfer coefficient increase on flow conditions. |

| Phase Distribution | Improved fluid distribution observed via IR thermography | Better phase behavior and flow uniformity with desuperheating. |

| Pressure Drop | No significant effect reported | Desuperheating does not adversely affect pressure drop in the heat exchanger. |

| Heat Transfer Mechanism | Forced convection with liquid film | Explains how desuperheating enhances condensation and heat transfer. |

Desuperheating also helps maintain stable operation by preventing excessive compressor discharge temperatures. This stability leads to longer equipment life and more consistent cooling performance. By ensuring the refrigerant enters the condensation stage at the right temperature, desuperheating supports the efficiency and reliability of the entire refrigeration cycle.

Condensing Process in the Condenser

Phase Change from Vapor to Liquid

The condenser in a refrigeration system performs a critical function during the condensing process. As the refrigerant enters the condenser, it arrives as a hot, high-pressure vapor. The main event inside the condenser is the transformation of this vapor into a liquid. This phase change is called condensation and involves the release of latent heat.

Researchers define condensation as the process where vapor molecules lose energy and come together to form a liquid. This transformation depends on several factors:

- Surface tension and wettability of the condenser tubes

- Properties of the refrigerant, such as density and specific heat

- Temperature difference between the refrigerant and the cooling medium

- Pressure and flow rate inside the condenser

- Geometry and surface area of the condenser

Scientists use predictive models like the Rohsenow, Chen, and Nusselt correlations to estimate how efficiently heat transfers during this phase change. These models help engineers design condensers that maximize performance.

Several case studies and simulations support the understanding of vapor-to-liquid phase change:

- Engineers developed a multi-phase solver that incorporates four popular phase change models.

- They conducted 171 simulations to compare how well these models predict condensation under different conditions.

- The results matched experimental data, especially under cryogenic conditions, confirming the accuracy of these models.

Thermodynamic properties play a key role in this process. Latent heat, specific heat capacity, and density determine how much energy the refrigerant must lose to become a liquid. Molecular dynamics simulations show that as vapor cools, molecules move closer together. Intermolecular forces, such as hydrogen bonding and van der Waals forces, help stabilize the liquid phase. Scientists observe changes in radial distribution functions, which reveal how molecules arrange themselves during condensation.

The phase change also involves nucleation and growth of liquid droplets. The rate at which vapor turns into liquid depends on the temperature difference and the energy required to form stable clusters of molecules. This process happens rapidly inside the condenser, ensuring that the refrigerant is ready for the next stage of the cooling cycle.

Note: The efficiency of this phase change directly affects the overall performance of the refrigeration system.

How Heat Is Released to the Environment

During condensation, the refrigerant must release a large amount of heat to the environment. The condenser in a refrigeration system acts as the bridge between the hot refrigerant and the cooler surroundings. This heat rejection occurs through several mechanisms, including sensible cooling, latent cooling, and radiant cooling.

Analytical data from validated models show the breakdown of heat exchange efficiency:

| Cooling Mode | Percentage Contribution |

|---|---|

| Sensible Cooling | 55.5% |

| Latent Cooling | 17.3% |

| Radiant Cooling | 27.2% |

Natural convection serves as the main mode of heat transfer in most condensers. The refrigerant first loses sensible heat, which lowers its temperature to the saturation point. As condensation begins, the refrigerant releases latent heat, which is the energy required for the phase change. Radiant cooling also plays a role, especially in systems with large surface areas.

The heat transfer process depends on several factors:

- Temperature difference between the refrigerant and the cooling medium (air or water)

- Flow rate of air or water across the condenser coils

- Surface area and cleanliness of the condenser

- Thermal conductivity of the materials used

Engineers use characteristic equations to evaluate cooling performance. They compare the cooling capacity per unit area to other systems, finding that well-designed condensers outperform many traditional cooling methods. The combination of sensible and latent cooling, along with efficient heat rejection, ensures that the refrigerant leaves the condenser as a subcooled liquid, ready for expansion.

Tip: Regular maintenance, such as cleaning condenser coils and ensuring proper airflow, helps maintain high heat exchange efficiency and prolongs equipment life.

Subcooling in the Condenser

Lowering the Temperature of Liquid Refrigerant

Subcooling occurs after the refrigerant has condensed from vapor to liquid. In this stage, the liquid refrigerant cools further below its saturation temperature. This process ensures that only liquid, not vapor, enters the expansion valve. Lowering the temperature of the liquid refrigerant increases the system’s cooling capacity and prevents the formation of unwanted vapor bubbles.

Researchers have measured several parameters to show the impact of subcooling on system performance:

| Parameter | Measured Value / Range | Significance / Impact |

|---|---|---|

| Inlet temperature of cooling liquid | Optimal at 22 °C (critical range 22–24 °C) | Key factor affecting cooling performance |

| Cooling power | Up to 210 W at 35 °C ambient | Indicates effective heat removal capacity |

| Coefficient of performance (COP) | Maximum 3.3 | Efficiency measure of the cooling system |

| Microclimate temperature | Reduced to about 28.5 °C | Demonstrates temperature reduction near the body |

| Relative humidity in microclimate | Reduced from 90% to 58% | Shows improvement in moisture control and comfort |

| Refrigerants compared | Water and 40% glycerol | Different energy efficiency and cooling effects noted |

These results confirm that lowering the liquid refrigerant temperature to around 22 °C can significantly improve cooling power, efficiency, and comfort in cooling applications.

Benefits of Subcooling for System Efficiency

Subcooling provides several important benefits for refrigeration systems. By ensuring that the refrigerant is fully liquid before expansion, subcooling increases the amount of heat the system can absorb in the evaporator. This leads to higher cooling efficiency and better overall performance.

- The degree of subcooling directly affects key performance indicators:

- COP (coefficient of performance)

- Exergetic efficiency

- Total irreversibility

- Compressor work

- Simulation studies show that an optimal subcooling degree of about 18 °C maximizes COP and exergetic efficiency, while minimizing irreversibility and compressor workload.

- Comparative research finds that subcooling can improve COP by up to 18%, depending on the refrigerant used.

- Both experimental and theoretical studies confirm that optimizing subcooling reduces exergy destruction and enhances system efficiency.

A field study in a Swedish supermarket demonstrates that integrating ground source subcooling into the refrigeration system results in a 9% annual energy savings. This improvement also lowers operating costs and reduces CO₂ emissions, highlighting the environmental and economic advantages of subcooling.

Tip: Regularly monitoring and optimizing subcooling can help maintain peak system performance and energy efficiency.

The Condenser in a Refrigeration System and System Performance

Impact on Cooling Efficiency

The condenser in a refrigeration system plays a direct role in determining cooling efficiency. When the condenser operates efficiently, the system uses less energy and delivers better cooling performance. Several performance metrics help engineers and technicians monitor and optimize this process:

- The Coefficient of Performance (COP) and Coefficient of System Performance (COSP) link condenser efficiency to overall system output. COP measures system efficiency without Condenser Fan power, while COSP includes it.

- Superheating and subcooling at the condenser outlet serve as important indicators. These parameters show how well the condenser prepares the refrigerant for the next stage.

- Discharge pressure reflects refrigerant charge levels and system health.

- Refrigerant charge levels must stay within a ±25% range from the design value. Deviations can reduce condenser efficiency and overall performance.

- Monitoring these factors allows for energy optimization and improved system reliability.

Recent studies show that lowering the condenser inlet temperature by 5.4 °C with advanced cooling methods, such as supersonic spray cold-water systems, can reduce power consumption by up to 14.4%. Pre-cooling technologies, including EC pads and mist cooling, also improve cooling capacity and reduce temperature differences across the condenser. Thermodynamic models confirm that even a 1 °C increase in cooling water temperature can decrease output power and thermal efficiency, highlighting the importance of condenser performance.

Signs of Condenser Issues

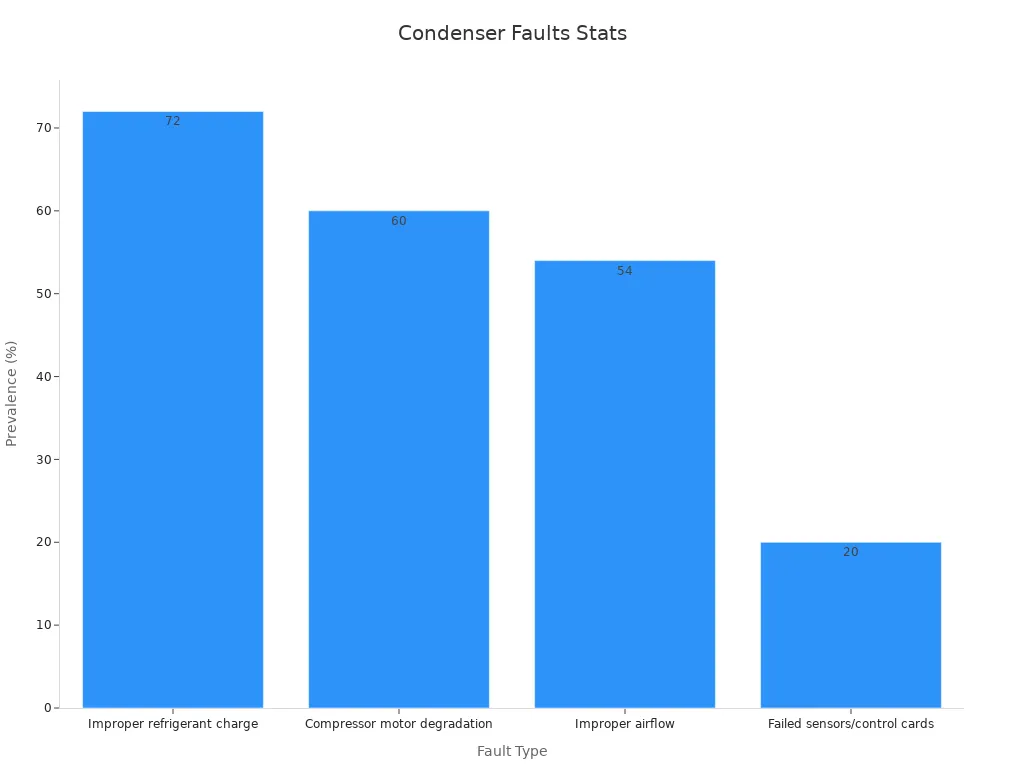

Early detection of condenser problems helps maintain system efficiency and prevent costly breakdowns. Technicians use several diagnostic tools and statistical trends to identify faults. The table below summarizes common issues and their prevalence:

| Fault Type | Prevalence (%) | Notes on Detection and Impact |

|---|---|---|

| Improper refrigerant charge | 72 | Soft fault, difficult to detect, can develop into hard faults |

| Compressor motor degradation | 60 | Significant impact on system performance |

| Improper airflow | 54 | Affects condenser efficiency and fault detection |

| Failed sensors/control cards | 20 | Can combine with other faults, complicating diagnosis |

Most faults in refrigeration systems are soft faults. These issues are harder to detect but can lead to more serious problems if left unaddressed. Advanced diagnostics, such as virtual sensors and deep learning models, help estimate airflow rates and detect condenser fouling. These tools compare expected and actual performance, allowing technicians to isolate faults and recommend timely service. By monitoring these signs, operators can protect comfort, reduce energy use, and extend system lifespan.

The condenser in a refrigeration system enables the refrigerant to release heat and change from gas to liquid, making cooling possible. Each stage—desuperheating, condensing, and subcooling—supports efficient heat removal. Case studies on multi-stage systems, such as those in cryogenic plants and data centers, show that dividing the process into stages improves energy efficiency and system stability. Reliable condenser operation ensures effective refrigeration, even in demanding environments.

FAQ

What is the main purpose of a condenser in a refrigeration system?

The condenser removes heat from the refrigerant. It changes the refrigerant from a hot vapor to a cool liquid. This process allows the system to provide effective cooling.

How does subcooling improve refrigeration efficiency?

Subcooling lowers the temperature of the liquid refrigerant below its condensation point. This step prevents vapor bubbles from forming at the expansion valve. The system then absorbs more heat in the evaporator, which increases efficiency.

What are common signs of condenser problems?

Technicians often notice higher energy use, reduced cooling, or unusual noises. Dirty coils, poor airflow, or refrigerant leaks can also signal condenser issues. Regular maintenance helps prevent these problems.

Why is desuperheating important in the condenser?

Desuperheating cools the superheated vapor to its saturation temperature. This step prepares the refrigerant for condensation. Efficient desuperheating protects system components and ensures reliable operation.