Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

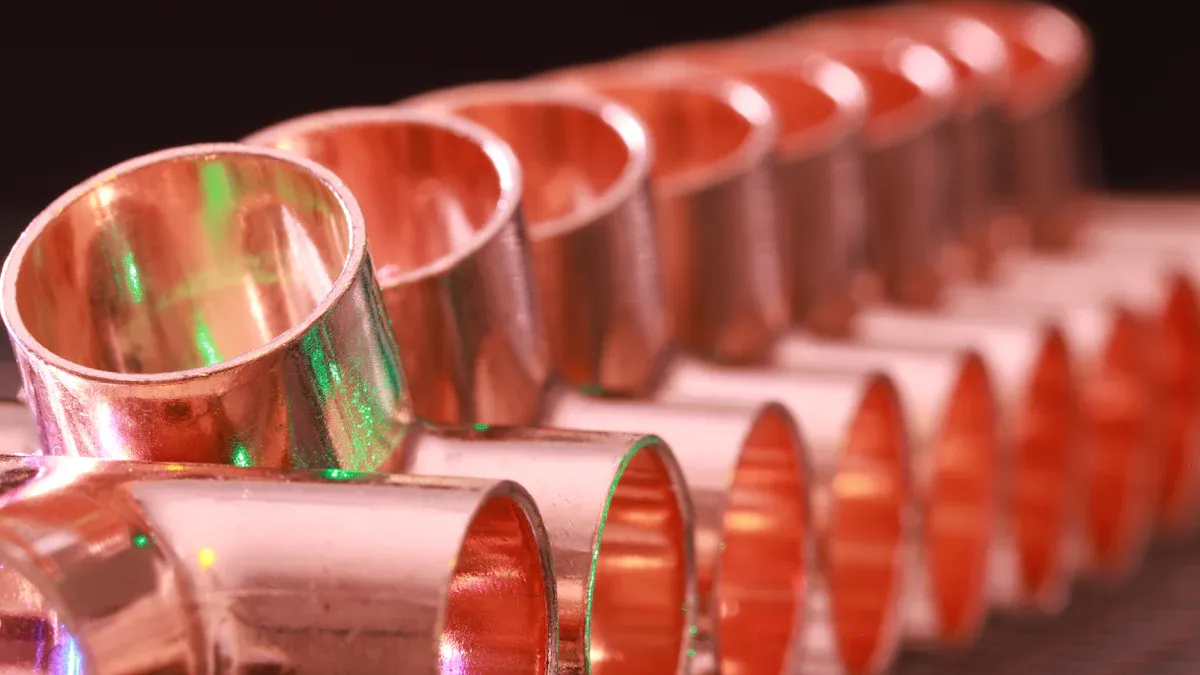

Top Copper Pipe Fitting Makers in 2025

Copper Pipe fittings play a crucial role in residential, medical, and industrial applications due to their unmatched properties. These fittings are highly valued for their corrosion resistance and thermal conductivity, making them indispensable in plumbing and HVAC systems. Theglobal construction copper pipes market, valued at $12.5 billion in 2023, is projected to reach $18.9 billion by 2032, driven by rising construction activities and the demand for sustainable solutions. In medical settings, copper's antibacterial properties reduce germs by 90%, ensuring safer environments. Top Copper Fittings for refrigerator applications also stand out for their efficiency and durability, further highlighting the versatility of copper in modern systems.

Key Takeaways

- Copper pipe fittings are important for plumbing, HVAC, and medical uses. They last long and don’t rust easily.

- The global market for copper pipes is growing fast. It may reach $18.9 billion by 2032 because of building projects and eco-friendly needs.

- Top companies like TSI Technologies and Viega USA focus on new ideas and high-quality products for many industries.

- ISO certifications matter a lot for companies. These prove their products are good and meet world standards.

- Copper fittings are popular in hospitals because they kill germs. They cut bacteria by 90%, making places safer.

- When picking a company, check their products, certifications, and reputation. This helps you find the right one for your needs.

- Different ways to connect pipes, like soldering and brazing, work well for different jobs. They make strong, leak-free joints.

- Copper moves heat very well, so it’s great for cooling systems. It makes them work better and last longer.

Leading Copper Pipe Fitting Manufacturers

TSI Technologies

Specializes in HVAC solutions and adheres to ISO standards.

TSI Technologies has established itself as a leader in copper pipe fittings for HVAC systems. The company focuses on delivering high-performance solutions that meet stringent ISO standards, ensuring reliability and efficiency in heating, ventilation, and air conditioning applications. Its innovative approach includes automated production lines capable of manufacturing thinner-walled copper tubes,down to 0.25 mm, without compromising pressure ratings. This advancement reduces material usage while maintaining durability, aligning with the industry's push for sustainable practices.

Key features of TSI Technologies' products include:

- Exceptional heat and pressure resistance for demanding HVAC environments.

- Corrosion-resistant materials that extend service life.

- Precision-engineered fittings for seamless installation.

Viega USA

Offers a wide range of materials, including copper, stainless steel, and polymers.

Viega USA stands out for its diverse product portfolio, catering to various industries with copper, stainless steel, and polymer fittings. The company's commitment to innovation has driven significant growth, with copper alloy advancements contributing to a 15% year-over-year revenue increase in 2023. Viega's global footprint includes major facilities in China, India, and Brazil, ensuring widespread availability and support for its products.

Notable attributes of Viega USA's fittings include:

- Compatibility with multiple connection methods, such as soldering and brazing.

- Customization options for size, wall thickness, and surface finishes.

- Certifications like EN 10204 3.1/3.2 Material Test Certificates, guaranteeing quality assurance.

NIBCO INC.

Provides flow control systems and holds ISO 9001:2015 certification.

NIBCO INC. excels in manufacturing flow control systems, offering a comprehensive range of copper pipe fittings designed for residential, commercial, and industrial applications. The company's adherence to ISO 9001:2015 certification underscores its commitment to quality and consistency. NIBCO's products are engineered to withstand high temperatures and pressures, making them ideal for demanding environments.

A closer look at NIBCO INC.'s offerings reveals:

| Specifications | Details |

|---|---|

| Size Range | ½” NB to 48” NB for Buttweld Pipe Fittings; ½” NB to 4” NB for Forged Fittings. |

| Wall Thickness | SCH 10 to SCH XXS. |

| End Connection Types | Beveled, Plain, Threaded, and Socket Weld Ends. |

| Surface Finishes | Black Painting, Galvanized, Pickled, and Polished. |

These features ensure easy installation, high durability, and excellent corrosion resistance, making NIBCO INC. a trusted name in the copper pipe fitting industry.

Ningbo Taojun Refrigeration Equipment Co., Ltd.

Specializes in refrigeration fittings, including condensers and stop valves, and serves global markets with certifications like ISO9001:2008 and US UL.

Ningbo Taojun Refrigeration Equipment Co., Ltd. has earned a reputation as a leader in the refrigeration industry. Established in 1988, the company has grown into a comprehensive enterprise that integrates design, production, and sales of refrigeration accessories. Its product portfolio includes condensers, stop valves, Filter Dryers, and other essential refrigeration components. These products are widely used in air conditioning systems, refrigerators, and industrial cooling applications.

The company’s commitment to quality is evident through its certifications, including ISO9001:2008 and US UL. These certifications ensure that its products meet international standards for safety and performance. Additionally, its dedication to innovation has led to partnerships with global brands such as Haier, Whirlpool, and Electrolux.

Key highlights of Ningbo Taojun's offerings include:

- Wide Product Range: From brass and copper accessories to air conditioning cable ties, the company provides solutions for diverse refrigeration needs.

- Global Reach: Its products are exported to Europe, America, Southeast Asia, and the Middle East, ensuring a strong international presence.

- Technological Advancements: Continuous investment in process innovation and equipment upgrades enables the production of first-class products.

Note: The "Lingshan" filter, a flagship product of Ningbo Taojun, has become a well-known brand in the domestic refrigeration market, reflecting the company’s focus on customer satisfaction and reliable performance.

Lokring Technology

Serves industries such as medical devices and marine.

Lokring Technology stands out for its innovative pipe connection solutions, which eliminate the need for welding. This approach ensures safer and more efficient installations across industries such as medical devices and marine. Lokring fittings are designed to provide leak-proof connections, making them ideal for critical applications like hazardous services and medical gas systems.

The company’s products undergo rigorous testing to ensure durability and reliability. Regulatory approvals, such as pre-certification status from the California Air Resources Board (CARB), further validate the quality of Lokring’s offerings.

| Evidence Type | Description |

|---|---|

| Regulatory Approval | CARB granted LOKRING pre-certification status, equivalent to WELDED status. |

| Mechanical Testing | Extensive testing demonstrated the integrity of LOKRING connections across various applications. |

| Application Standards | Approved for critical uses, including hazardous services and medical gases. |

Lokring’s ability to meet stringent industry standards has made it a trusted partner for clients in demanding sectors. Its fittings are particularly valued in marine environments, where resistance to corrosion and high-pressure conditions is essential.

Coronet Parts Mfg. Co., Inc.

Custom manufacturer for plumbing and automotive applications.

Coronet Parts Mfg. Co., Inc. specializes in custom manufacturing of copper pipe fittings for plumbing and automotive industries. The company’s expertise lies in creating tailored solutions that meet specific client requirements. Its product range includes fittings for water supply systems, fuel lines, and HVAC applications.

Coronet’s focus on customization allows it to cater to niche markets, providing unique designs and specifications that standard fittings cannot fulfill. The company employs advanced manufacturing techniques to ensure precision and consistency in its products.

Key features of Coronet’s services include:

- Custom Design Capabilities: Ability to produce fittings in various sizes, shapes, and materials.

- High-Quality Standards: Products undergo strict quality control to ensure durability and performance.

- Industry Expertise: Decades of experience in plumbing and automotive sectors enable the company to deliver reliable solutions.

Coronet Parts Mfg. Co., Inc. continues to innovate and adapt to changing market demands, solidifying its position as a trusted name in the copper pipe fitting industry.

Other Notable Manufacturers

Includes Cash Acme, ASC Engineered Solutions, and more.

The copper pipe fitting industry boasts a diverse range of manufacturers that contribute significantly to its growth and innovation. Beyond the leading names, several other companies have established themselves as key players, offering specialized products and services that cater to various market needs. These manufacturers enhance the competitive landscape by driving advancements in technology, quality, and customer satisfaction.

Cash Acme

Cash Acme has earned a reputation for its high-quality plumbing solutions, particularly in pressure regulator valves and fittings. The company focuses on delivering products that simplify installation while maintaining durability and performance. Its SharkBite® push-to-connect fittings have revolutionized the industry by providing a tool-free, leak-proof connection method. These fittings are widely used in residential and commercial plumbing systems, making Cash Acme a trusted name among contractors and homeowners alike.

ASC Engineered Solutions

ASC Engineered Solutions specializes in pipe joining and flow control products, including copper fittings. The company emphasizes precision engineering and rigorous quality control to meet the demands of industrial and commercial applications. Its copper fittings are designed to withstand high pressures and temperatures, ensuring reliability in critical systems. ASC's commitment to sustainability is evident in its use of recycled materials and energy-efficient manufacturing processes.

Additional Industry Leaders

Several other manufacturers play pivotal roles in shaping the copper pipe fitting market. Their contributions span innovation, market presence, and strategic initiatives. The table below highlights some of these notable companies and their key attributes:

| Manufacturer Name | Key Attributes |

|---|---|

| Ningbo Jintian Copper | Strong market presence, extensive product portfolio, advanced technologies |

| Shanghai Longyang Precision Composite Copper | Significant influence in innovation and competition, strategic initiatives |

| Henan Yuxing Copper | Recognized for core strengths and competitive strategies |

| Qingdao Hongtai Copper | Plays a crucial role in shaping consumer preferences and industry standards |

| Jinlong Precision Copper Tube Group | Engaged in mergers, acquisitions, and new product launches |

| Shandong Dongzhi Metal Products | Contributes to industry benchmarks and competitive landscape |

| Runlong Metal Materials | Important player in the copper pipe market |

| Shandong Xuanchitongguanchangjia | Notable for its market share and recent developments |

| Miracle | Recognized for its strategic positioning in the market |

| Guangdong Jingyi Metal Co., Ltd. | Significant contributor to the competitive landscape |

| Jiangxi Copper Group | Major player with a strong market presence |

| Jiangsu Cuilong Precision Copper Tube | Engaged in strategic initiatives and product innovation |

These companies demonstrate the industry's dynamic nature, with each contributing unique strengths to the market. For instance, Jiangxi Copper Group leverages its extensive resources to maintain a dominant position, while Jinlong Precision Copper Tube Group drives growth through mergers and product launches. Similarly, Qingdao Hongtai Copper influences consumer preferences by setting high standards for quality and innovation.

Tip: When selecting a manufacturer, consider factors such as product range, certifications, and market reputation to ensure the best fit for your project needs.

The collective efforts of these manufacturers ensure that the copper pipe fitting industry continues to thrive, meeting the evolving demands of residential, industrial, and commercial applications. Their contributions not only enhance product quality but also foster innovation, sustainability, and global competitiveness.

Ranking Criteria for Top Manufacturers

Click Share Analysis

Rankings based on click share percentages as of May 2025.

Click share analysis plays a pivotal role in identifying the top copper pipe fitting manufacturers. This metric reflects the percentage of online engagement each company garners, offering insights into their market influence and customer interest. In May 2025, manufacturers like TSI Technologies and Viega USA led the rankings due to their innovative product offerings and strong digital presence.

Companies with higher click shares often demonstrate superior brand recognition and customer trust. For instance, Ningbo Taojun Refrigeration Equipment Co., Ltd. saw a significant increase in click share after expanding its global distribution network. This growth highlights the importance of digital marketing and customer-centric strategies in maintaining a competitive edge.

Tip: Businesses aiming to improve their click share should focus on enhancing their online visibility through targeted campaigns and user-friendly websites.

Certifications and Standards

Importance of ISO certifications and industry-specific standards.

Certifications and standards ensure that copper pipe fittings meet stringent quality and safety requirements. ISO certifications, in particular, validate a manufacturer’s commitment to excellence and compliance with international benchmarks. For example, ISO 2016:1981 specifies the assembly dimensions and tests for capillary solder fittings, ensuring compatibility and reliability in various applications.

| Standard Number | Description |

|---|---|

| ISO 2016:1981 | Capillary solder fittings for copper tubes; Assembly dimensions and tests |

Manufacturers like NIBCO INC. and Ningbo Taojun Refrigeration Equipment Co., Ltd. emphasize obtaining certifications such as ISO 9001:2015 and US UL. These endorsements not only enhance product credibility but also reassure customers about performance consistency.

Adherence to industry-specific standards further distinguishes top manufacturers. For instance, HVAC-focused companies prioritize compliance with ASHRAE guidelines, while medical device suppliers align with FDA regulations. This specialization ensures that products meet the unique demands of their respective sectors.

Industry Specialization

Focus on industries served, such as HVAC, medical, and plumbing.

Industry specialization allows manufacturers to tailor their products to specific market needs. Companies like TSI Technologies excel in the HVAC sector by offering fittings designed to withstand high temperatures and pressures. Similarly, Lokring Technology caters to the medical and marine industries with leak-proof connections that eliminate the need for welding.

Plumbing remains a core focus for many manufacturers, including Coronet Parts Mfg. Co., Inc., which provides custom fittings for water supply systems. Refrigeration is another critical area, with Ningbo Taojun Refrigeration Equipment Co., Ltd. leading the way in condensers and stop valves.

Specialization not only enhances product quality but also fosters innovation. By concentrating on niche markets, manufacturers can develop advanced solutions that address specific challenges, such as corrosion resistance in marine environments or antibacterial properties in medical settings.

Note: When selecting a manufacturer, consider their industry expertise to ensure the best fit for your project requirements.

Global Distribution of Copper Pipe Fitting Manufacturers

United States

Home to 22 manufacturers and distributors with a 100% market share.

The United States dominates the copper pipe fitting market with 22 manufacturers and distributors contributing to a 100% market share within the region. This stronghold reflects the country’s advanced infrastructure and high demand for copper fittings in residential, industrial, and medical applications. American manufacturers prioritize innovation and quality, adhering to strict standards such as ISO certifications and ASHRAE guidelines.

The U.S. market benefits from increasing construction projects and the rising trend of rainwater harvesting. Urbanization has also played a significant role in driving demand for copper fittings, as cities expand and modernize their plumbing and HVAC systems. Additionally, the country’s focus on healthcare infrastructure upgrades has bolstered the use of copper in medical facilities, where its antimicrobial properties ensure safe and sterile environments.

Key factors contributing to the U.S. market’s dominance include:

- Unmatched strength and durability of copper fittings.

- Recyclability, aligning with sustainability goals.

- Antimicrobial properties, essential for medical and residential applications.

The demand for copper fittings in the U.S. is expected to remain stable, supported by ongoing investments in construction and healthcare sectors.

Other Regions

Overview of manufacturers' presence in Europe, Asia, and other regions.

Globally, the copper pipe fitting market is experiencing steady growth, with a projected compound annual growth rate (CAGR) of 5.1% from 2023 to 2032. The market size, valued at $35.70 billion in 2023, is expected to reach $55.86 billion by 2032. This growth is driven by urbanization, increased awareness of copper’s benefits, and the expansion of construction projects worldwide.

| Year | Market Size (USD Billion) | CAGR (%) |

|---|---|---|

| 2023 | 35.70 | N/A |

| 2025 | 18.17 | N/A |

| 2032 | 55.86 | 5.1 |

In Europe, manufacturers focus on producing high-quality fittings that meet stringent environmental and safety standards. The region’s emphasis on sustainability has led to the adoption of recycled copper materials in production. Consumption growth rates in Europe have shown consistent increases, reflecting the region’s commitment to modernizing its infrastructure.

Asia-Pacific, home to some of the largest copper fitting manufacturers, plays a pivotal role in the global market. Countries like China and India lead in production and consumption, driven by rapid urbanization and industrialization. The region’s manufacturers benefit from lower production costs and access to abundant raw materials, enabling them to compete effectively on a global scale.

| Metric | Region | Year | Value |

|---|---|---|---|

| Production Value | Global | 2019-2024 | Detailed data available |

| Market Share | Global | 2019-2024 | Detailed data available |

| Consumption Growth Rate | Europe | 2019, 2023, 2030 | Detailed data available |

| Consumption Growth Rate | Asia Pacific | 2019, 2023, 2030 | Detailed data available |

The Middle East and Africa are emerging markets for copper pipe fittings, driven by investments in infrastructure and water management systems. These regions are increasingly adopting copper fittings for their durability and resistance to extreme temperatures, making them ideal for harsh climates.

Tip: Businesses looking to expand globally should consider the unique demands and regulations of each region to maximize their market potential.

The global distribution of copper pipe fitting manufacturers highlights the industry’s dynamic nature. Each region contributes unique strengths, ensuring the continued growth and innovation of this essential market.

Types of Copper Pipe Fittings Produced

Common Fitting Types

Includes biting joints, brass fittings, and flare joints.

Copper pipe fittings come in various types, each designed to meet specific application requirements. These fittings are essential in industries such as construction, HVAC, plumbing, and electronics due to their versatility and durability.

- Biting Joints: These fittings use a compression mechanism to create a secure connection. They are ideal for applications requiring quick assembly and disassembly, such as plumbing repairs.

- Brass Fittings: Combining copper and zinc, brass fittings offer enhanced corrosion resistance and strength. They are widely used in water supply systems and industrial applications.

- Flare Joints: These fittings feature a flared end that connects to a corresponding fitting using a threaded nut. Flare joints are commonly employed in refrigeration and air conditioning systems due to their ability to withstand high pressures.

Copper fittings are recognized for their excellent thermal conductivity, corrosion resistance, and recyclability. These characteristics make them a preferred choice for applications requiring heat transfer, reliability, and longevity.

Tip: When selecting a fitting type, consider factors such as pressure requirements, ease of installation, and compatibility with the piping system.

Connection Methods

Soldering, brazing, screw-tightened, and plug-in fittings.

The methods used to connect copper pipe fittings have evolved significantly over time, offering improved efficiency and reliability.

Soldering remains one of the most popular techniques for joining copper pipes. This method involves melting a filler metal to create a leak-proof seal. Its widespread use dates back to the introduction of the electric soldering iron in 1921, which simplified the process for residential and commercial applications.

Brazing, another common method, uses a higher melting point filler metal to form stronger joints. This technique is particularly effective for smaller pipes, where heat distribution challenges are minimized. Brazing is favored in industries requiring durable connections, such as HVAC and refrigeration.

Compression fittings, also known as screw-tightened fittings, emerged as a user-friendly alternative post-World War II. These fittings allow homeowners to create secure connections without specialized tools. Their simplicity and reliability make them a popular choice for plumbing systems.

Plug-in fittings, including press fittings, represent a modern innovation in pipe joining. These fittings eliminate the need for heat, offering a safer and faster installation process. Features such as visual indicators for unpressed connections enhance their reliability, making them ideal for both residential and industrial applications.

Note: Each connection method has unique advantages. Soldering and brazing provide durability, while screw-tightened and plug-in fittings offer convenience and ease of use.

Copper pipe fittings and their connection methods continue to evolve, driven by advancements in technology and industry demands. These innovations ensure that copper remains a cornerstone material in plumbing, HVAC, and refrigeration systems.

Applications of Copper Pipe Fittings

Residential Use

Water supply and hot water systems.

Copper pipe fittings are a cornerstone of residential plumbing systems, particularly for water supply and hot water distribution. Their durability and corrosion resistance make them a preferred choice for homeowners and contractors alike. Over the decades, copper has proven its reliability in residential applications.

- Leaks in copper water tubes are rare, with most issues arising from internal corrosion rather than material failure.

- Copper alloys naturally resist corrosion due to the formation of protective films, ensuring long-term performance.

A historical analysis of copper usage in residential water systems highlights its dominance:

| Year | Linear Feet Installed (in billions) | Percentage of Total Water Distribution Pipe |

|---|---|---|

| 1980 | 0.5 | >50% |

| 1994 | 1.0 | >80% |

Copper pipe fittings also comply with the U.S. Safe Drinking Water Act and the Lead and Copper Rule. These regulations ensure that public water suppliers provide safe, non-corrosive drinking water by adjusting pH levels and using corrosion inhibitors. This compliance underscores copper's role in maintaining water quality and safety in residential settings.

Medical and Industrial Use

Air conditioning, medical gas systems, and more.

Copper pipe fittings are indispensable in medical and industrial applications due to their strength, reliability, and compliance with stringent standards. In healthcare facilities, copper fittings are used to distribute critical medical gases like oxygen and nitrogen. These systems must meet rigorous specifications to ensure patient safety and operational efficiency.

| Standard | Description |

|---|---|

| ASTM B819 | Requirements for seamless copper tubes for medical gas systems. |

| EN 13348 | Specifies seamless, round copper tubes for medical gas pipeline systems. |

In industrial settings, copper fittings excel in air conditioning systems, where they facilitate efficient heat transfer and withstand high pressures. Their ability to resist corrosion and maintain structural integrity under extreme conditions makes them ideal for demanding environments. Copper's versatility extends to other industrial applications, including refrigeration, fuel lines, and hydraulic systems, where precision and durability are paramount.

Refrigeration Systems

Highlighting top copper fittings for refrigerator applications, including products from Ningbo Taojun Refrigeration Equipment Co., Ltd.

Refrigeration systems rely heavily on copper pipe fittings for their superior thermal conductivity, durability, and ease of installation. Copper's thermal conductivity is approximately 20 times higher than stainless steel and more than twice that of aluminum, making it an excellent choice for heat transfer in refrigeration systems.

Ningbo Taojun Refrigeration Equipment Co., Ltd. stands out as a leader in this sector. The company offers a wide range of products, including condensers, stop valves, and filter dryers, which are essential components in modern refrigeration systems. These products are designed to withstand high pressures and extreme temperatures, ensuring reliable performance in both residential and industrial refrigeration applications.

Key advantages of copper fittings in refrigeration systems include:

- Durability: Copper's strength reduces the risk of cracking or splitting under pressure.

- Corrosion Resistance: A protective oxide layer prevents corrosion, unlike brass fittings that may suffer from dezincification.

- Ease of Installation: Copper tubes can be bent and joined easily, allowing for complex configurations.

The top copper fittings for refrigerator applications, such as those produced by Ningbo Taojun, exemplify these benefits. Their products are widely used in air conditioning systems, refrigerators, and industrial cooling systems, reflecting their commitment to quality and innovation. By leveraging copper's unique properties, these fittings enhance the efficiency and reliability of refrigeration systems worldwide.

Tip: When selecting copper fittings for refrigeration, prioritize products with proven durability and thermal efficiency to ensure optimal system performance.

The top copper pipe fitting manufacturers in 2025, including TSI Technologies, Viega USA, NIBCO INC., and Ningbo Taojun Refrigeration Equipment Co., Ltd., have significantly shaped the industry. Their innovative solutions and adherence to quality standards have driven advancements across residential, medical, industrial, and refrigeration sectors.

| Evidence Description | Key Insights |

|---|---|

| HVAC Market Share | HVAC systems dominate as the largest end-user segment, driving copper demand. |

| Competitive Landscape | Companies like Luvata and Cerro Flow Products highlight a competitive market. |

| Regional Insights | Asia Pacific leads the market, fueled by infrastructure growth and EV demand. |

These manufacturers excel by diversifying their product portfolios, ensuring resilience during market fluctuations. For example, companies like P&G demonstrate how catering to varied consumer needs strengthens competitive differentiation.

Note: Certifications such as ISO 9001 and SQF further validate their commitment to quality, ensuring customer trust and satisfaction.

By understanding these manufacturers' specialties and strategic approaches, stakeholders can make informed decisions that align with their project requirements and industry trends.

FAQ

What are the primary benefits of using copper pipe fittings?

Copper pipe fittings offer excellent corrosion resistance, thermal conductivity, and durability. They are recyclable, making them environmentally friendly. Their antibacterial properties also make them ideal for medical and residential applications, ensuring safety and reliability in various systems.

How do I choose the right copper pipe fitting for my project?

Consider factors like application type, pressure requirements, and connection methods. For example, soldered fittings suit plumbing, while brazed fittings work well in HVAC systems. Always verify certifications like ISO 9001 to ensure quality and compatibility.

Which industries rely most on copper pipe fittings?

Copper pipe fittings are essential in HVAC, plumbing, medical, and refrigeration industries. They are also widely used in industrial cooling systems, fuel lines, and hydraulic systems due to their strength, reliability, and thermal efficiency.

Are copper pipe fittings suitable for high-pressure systems?

Yes, copper pipe fittings are ideal for high-pressure systems. Their strength and resistance to cracking ensure durability under extreme conditions. Brazed and flare fittings are particularly effective in applications requiring high-pressure tolerance.

What certifications should I look for when purchasing copper pipe fittings?

Look for ISO certifications like ISO 9001:2015, which ensure quality and safety. Industry-specific certifications, such as ASTM B819 for medical gas systems or US UL for refrigeration components, validate the product's compliance with international standards.

How do copper fittings compare to other materials like stainless steel?

Copper fittings excel in thermal conductivity and ease of installation. They are lighter and more flexible than stainless steel. However, stainless steel offers higher resistance to extreme temperatures and certain corrosive environments, making it better for specific industrial applications.

Can copper pipe fittings be used in refrigeration systems?

Yes, copper pipe fittings are widely used in refrigeration systems. Their superior thermal conductivity and corrosion resistance make them ideal for condensers, stop valves, and filter dryers. Manufacturers like Ningbo Taojun specialize in high-quality refrigeration fittings.

What connection methods are most common for copper pipe fittings?

Soldering and brazing are the most common methods, offering durable and leak-proof connections. Screw-tightened fittings provide convenience for quick installations, while plug-in fittings, such as press fittings, offer modern, heat-free alternatives for safer and faster assembly.

Tip: Always consult a professional or refer to manufacturer guidelines to ensure proper fitting selection and installation.