Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

Top 5 Applications of Finned Tube Condensers in HVAC Systems

Finned tube condensers play a pivotal role in modern HVAC systems, offering unmatched efficiency in heat transfer and energy conservation. Their innovative design enhances performance across residential, commercial, and industrial applications. As HVAC systems account for nearly 30% of energy consumptionin buildings, the demand for energy-efficient solutions has surged. Finned tube condensers meet this need by optimizing heat dissipation, making them indispensable in environments ranging from homes to data centers. These condensers dominate the market, comprising 70% of Hvac Condenser applications, underscoring their importance in sustainable cooling and heating solutions.

Key Takeaways

- Finned tube condensers save energy in HVAC systems. This lowers electricity bills for homes and businesses.

- These condensers keep temperatures steady, making homes and offices more comfortable. They stop areas from being too hot or cold.

- In factories, finned tube condensers control temperatures exactly. This is important for things like cold storage and making products.

- Finned tube condensers help the environment by using heat better. They also work with eco-friendly refrigerants to meet green goals.

- Data centers use finned tube condensers to handle high heat. This keeps equipment working well and avoids breakdowns.

Residential HVAC Condenser Applications

Energy Efficiency in Home Cooling

Finned tube condensers have revolutionized energy efficiency in home cooling systems. Their advanced design minimizes energy consumption by optimizing heat transfer, which directly reduces electricity costs for homeowners. Research highlights that applying nanomaterial coatings to these condensers can significantly enhance their performance. At a 50-degree inclination angle, condensate on coated surfaces increased by over 30%, while overall condenser efficiency improved by up to 78.7% with a 1% nanoparticle concentration. These advancements make finned tube condensers a cornerstone of modern HVAC condenser applications.

The benefits extend beyond efficiency. A study revealed that finned tube condensers reduce static pressure drop by 7–20.4% and increase heat transfer by 5.6–12.2%. This improvement allows for smaller condenser volumes, which can decrease by up to 20%, making them ideal for compact residential HVAC systems. Additionally, air flow rate declines by only 30%, ensuring consistent cooling performance even in high-demand scenarios. These features collectively enhance the energy efficiency of home cooling systems, making them more sustainable and cost-effective.

Enhancing Comfort in Residential Spaces

Comfort in residential spaces depends on maintaining consistent indoor temperatures, and finned tube condensers excel in this regard. Their ability to regulate heat transfer ensures that HVAC systems operate smoothly, providing uniform cooling throughout the home. This consistency eliminates hot and cold spots, creating a more comfortable living environment for residents.

Moreover, finned tube condensers improve the system's Coefficient of Performance (COP) by 3.8% to 6.2% compared to plain fins. This enhancement translates to better energy utilization, which not only reduces operational costs but also supports eco-friendly living. Optimized designs can further cut costs by up to 56%, making these condensers a practical choice for homeowners seeking both comfort and affordability. As a result, finned tube condensers have become a vital component of residential HVAC condenser applications, ensuring reliable performance and enhanced living standards.

Commercial HVAC Condenser Applications

Large-Scale Cooling and Heating Solutions

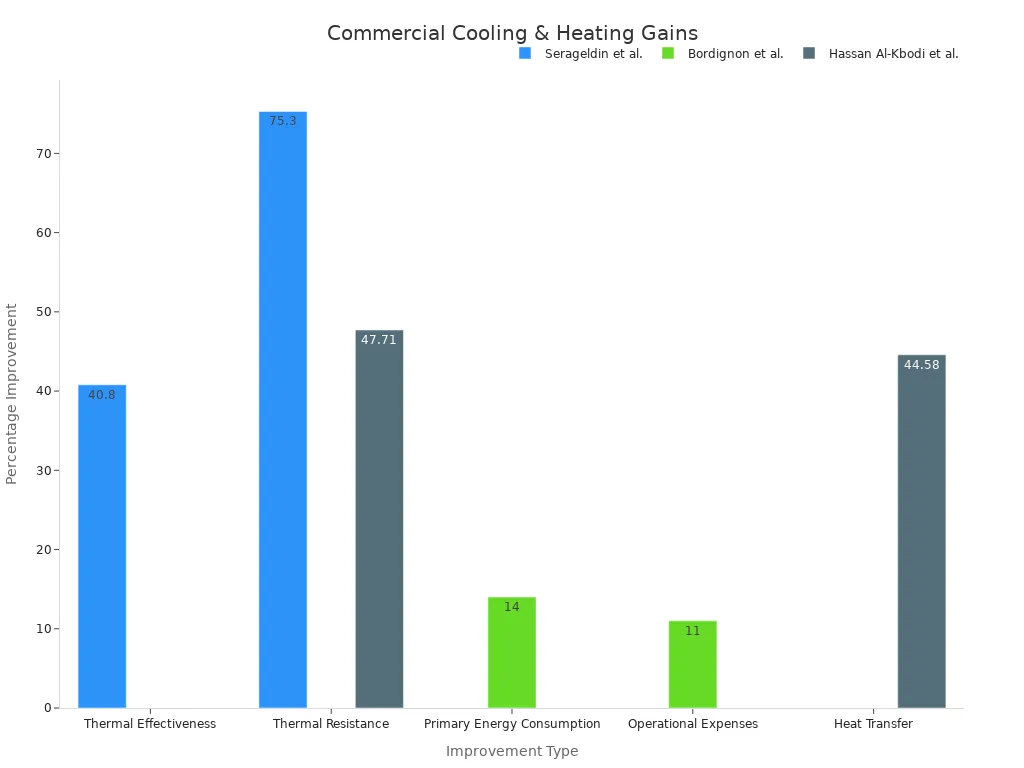

Finned tube condensers excel in large-scale cooling and heating systems, making them indispensable in commercial HVAC condenser applications. Their ability to handle high thermal loads ensures efficient operation in environments such as shopping malls, hospitals, and airports. These condensers optimize heat transfer, reducing energy consumption and operational costs. Studies have demonstrated their effectiveness in improving thermal performance. For instance, Serageldin et al. (2021) reported a 40.8% increase in thermal effectiveness and a 75.3% reduction in thermal resistance when using advanced designs.

The adoption of innovative geometries, such as oval cross-sections, further enhances performance. This design reduces thermal resistance by 18.47% and pressure drop by 32%, ensuring consistent operation even under demanding conditions. Additionally, the BasHE system has shown a 14% reduction in primary energy consumption and an 11% decrease in operational expenses, making it a cost-effective solution for large-scale applications.

These advancements highlight the role of finned tube condensers in creating sustainable and energy-efficient solutions for commercial spaces.

Optimizing Performance in Office and Retail Spaces

Office buildings and retail spaces demand precise temperature control to maintain comfort and productivity. Finned tube condensers meet these requirements by delivering consistent cooling and heating performance. Their compact design allows for seamless integration into modern HVAC systems, ensuring space efficiency without compromising functionality.

Case studies have highlighted their versatility in commercial HVAC condenser applications. For example, the use of small-diameter copper tubes in heat exchangers has significantly improved refrigerant efficiency. Research conducted by Bordignon et al. (2022) revealed a 14% reduction in primary energy consumption, while Hassan Al-Kbodi et al. (2024) demonstrated a 44.58% increase in heat transfer. These improvements translate to lower energy bills and reduced environmental impact.

The ability to transition to alternative refrigerants further enhances their appeal. A CDA webinar emphasized the importance of adapting heat exchanger designs to accommodate eco-friendly refrigerants, ensuring compliance with environmental regulations. This adaptability makes finned tube condensers a forward-thinking choice for office and retail HVAC systems.

Industrial HVAC Condenser Applications

Cold Storage and Manufacturing Processes

Finned tube condensers play a critical role in industrial settings, particularly in cold storage and manufacturing processes. These systems ensure efficient heat transfer, which is essential for maintaining low temperatures in cold storage facilities. By optimizing thermal performance, they help preserve perishable goods and maintain product quality. In manufacturing, finned tube condensers support processes that require precise temperature regulation, such as chemical production and metalworking.

Performance improvements in industrial applications highlight the effectiveness of these condensers. For example, a 29-MW waste-to-energy plant in the UK reported significant gains after cleaning its finned tube condensers. The vacuum improved from 0.7 bar to 0.9 bar, and power output increased from 26 MW to 28.29 MW. Additionally, advancements in fan design have reduced power consumption by 15% to 20%, while increasing volume flow rates by up to 20%. Structural improvements, such as lighter fan blades, have also minimized vibrational loads on gearboxes, enhancing system reliability.

| Improvement Type | Description |

|---|---|

| Fan Design | New fan design consumes 15% to 20% less power for similar flow displacement. |

| Volume Flow Rate | Volume flow rates can be increased by 10% to 20%. |

| Structural Improvements | Fan blade weight is reduced by 50%, leading to reduced vibrational loads on the gearbox. |

These innovations demonstrate the value of finned tube condensers in industrial HVAC condenser applications, ensuring energy efficiency and operational stability.

Precise Temperature Control for Industrial Needs

Industries requiring precise temperature control rely heavily on finned tube condensers. These systems are vital for processes like fermentation, where maintaining the correct temperature is critical for microorganism growth and product quality. Their compact design and enhanced heat transfer capabilities make them ideal for meeting the specific needs of industries such as pharmaceuticals and food production.

Key benefits include energy efficiency, reliable temperature regulation, and compactness. These features ensure that industrial processes run smoothly while minimizing energy consumption. For instance, tube fin heat exchangers provide consistent temperature control, which is essential for ensuring the quality of the final product. By delivering reliable performance, finned tube condensers support the stringent requirements of industrial operations.

Heat Pump HVAC Condenser Applications

Efficient Heating and Cooling Cycles

Finned tube condensers significantly enhance the efficiency of heating and cooling cycles in heat pump systems. Their advanced design optimizes heat transfer, ensuring consistent performance across varying environmental conditions. A comparative study of microchannel and finned-tube heat pump systems under frosting conditions revealed that microchannel technology reduces the frost period, improving the overall efficiency of heating and cooling cycles. This finding underscores the importance of innovative designs in maintaining system reliability and performance.

The effectiveness of finned tube condensers in heat pump applications is further supported by empirical data. Variations in fin count and dimensions improve heat dissipation, enhancing thermal management. The addition of microencapsulated phase change materials (PCMs) has been shown to decrease output temperatures by up to 4 °K, while the combined use of double spiral fins and PCMs results in a 7.5% improvement in heat exchanger efficiency. These advancements demonstrate the critical role of finned tube technology in optimizing heat pump performance.

| Findings | Implications |

|---|---|

| Variations in fin count and dimensions | Improved thermal management of heat pump systems |

| Finned heat sinks in boundary layer regions | Enhanced heat transfer capabilities |

| Increasing fin count over time | Affects thermal storage capacity negatively |

| Addition of microencapsulated PCM | Decreases output temperature by up to 4 °K |

| Double spiral fins with microencapsulated PCMs | 7.5% improvement in heat exchanger efficiency |

Eco-Friendly and Sustainable HVAC Solutions

Finned tube condensers contribute to eco-friendly and sustainable HVAC solutions by reducing energy consumption and supporting the use of environmentally friendly refrigerants. Advanced copper tube technology in heat exchangers plays a pivotal role in lowering energy demands for heating and cooling. Heat pumps equipped with finned tube condensers achieve high coefficients of performance (COPs), reaching values of approximately 4.5 under optimal conditions. This efficiency aligns with global efforts to meet Environmental, Social, and Governance (ESG) goals and the United Nations Sustainable Development Goals (UN SDGs).

Key trends in sustainable HVAC condenser applications include the transition to energy-efficient appliances and the adoption of alternative refrigerants. These innovations not only reduce operational costs but also minimize the environmental impact of HVAC systems. By integrating finned tube condensers, heat pump systems can achieve superior performance while adhering to stringent environmental standards.

- Advanced copper tube technology reduces energy demands for heating and cooling.

- High COPs of approximately 4.5 highlight the efficiency of heat pumps.

- Energy-efficient appliances support ESG and UN SDG objectives.

These features make finned tube condensers an essential component of sustainable HVAC systems, ensuring long-term environmental and economic benefits.

Data Center HVAC Condenser Applications

Managing Heat Loads in High-Density Environments

Data centers generate immense heat due to the high density of servers and computing equipment. Finned tube condensers play a vital role in managing these heat loads by optimizing heat transfer efficiency. Their advanced designs ensure consistent cooling, even in environments with fluctuating thermal demands. This capability prevents overheating, which can lead to equipment failure and costly downtime.

Performance data highlights the effectiveness of different condenser types in managing heat loads. For example:

| Condenser Type | Test UA vs Predicted UA | Air-side Effectiveness |

|---|---|---|

| Variable-fin core | 10% greater | 0.80 |

| Offset-fin core | 8% greater | 0.80 |

| Plain-fin core | 3% greater | 0.80 |

The variable-fin core demonstrated the highest performance, exceeding predictions by 10%. Offset-fin cores followed closely with an 8% improvement, while plain-fin cores showed a modest 3% gain. These results underscore the importance of selecting the right condenser type for high-density environments.

Finned tube condensers also enhance airflow management, ensuring uniform cooling across server racks. This feature reduces hotspots, which can compromise system reliability. Their compact design allows for seamless integration into data center HVAC systems, maximizing space efficiency without sacrificing performance.

Ensuring Reliability in Critical Infrastructure

Reliability is paramount in data centers, where even minor disruptions can have significant consequences. Finned tube condensers contribute to system stability by maintaining precise temperature control. Their robust construction ensures durability, reducing the risk of mechanical failures.

Advanced features, such as variable fin spacing, further enhance reliability. These designs adapt to changing thermal loads, ensuring consistent performance under varying conditions. Additionally, the use of corrosion-resistant materials extends the lifespan of condensers, minimizing maintenance requirements.

By integrating finned tube condensers, data centers can achieve optimal cooling efficiency while ensuring uninterrupted operation. This makes them an indispensable component of HVAC condenser applications in critical infrastructure.

Finned tube condensers have transformed HVAC systems by enhancing efficiency, sustainability, and performance. Their advanced designs optimize heat transfer, reduce energy consumption, and support eco-friendly practices. Studies highlight their impact:

| Study | Findings |

|---|---|

| Cattani et al. | Integrated HVAC systems recover rainwater and condensate, offering sustainable water solutions. |

| Yoon et al. | Portable air conditioners using condensate spraying increased COP by 16%. |

| Tan et al. | Coupled heat pump systems improved thermoelectric efficiency and reduced energy use. |

- Stainless steel finned tubes lower fuel consumption and carbon emissions.

- Their durability and recyclability align with environmental goals.

These innovations make finned tube condensers essential for optimizing HVAC systems, ensuring long-term benefits for diverse applications.

FAQ

What are finned tube condensers used for in HVAC systems?

Finned tube condensers improve heat transfer efficiency in HVAC systems. They are used for cooling, heating, and maintaining precise temperature control in residential, commercial, industrial, and data center applications.

How do finned tube condensers enhance energy efficiency?

Their design optimizes heat dissipation, reducing energy consumption. Advanced features like microchannel technology and nanomaterial coatings further improve performance, lowering operational costs and supporting sustainable practices.

Are finned tube condensers suitable for eco-friendly refrigerants?

Yes, finned tube condensers adapt to alternative refrigerants. Their compatibility ensures compliance with environmental regulations, making them ideal for sustainable HVAC systems.

Why are finned tube condensers important for data centers?

Data centers rely on finned tube condensers to manage high heat loads. Their compact design and efficient cooling prevent overheating, ensuring reliable operation of critical infrastructure.

Can finned tube condensers be customized for specific applications?

Manufacturers offer customizable designs to meet unique requirements. Variations in fin count, dimensions, and materials allow these condensers to perform optimally across diverse HVAC applications.