Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

Top 10 Reliable Wire Tube Condenser Manufacturers for Industrial Refrigeration Systems (2025)

Wire tube condensers serve as critical components in industrial refrigeration systems, ensuring efficient heat transfer and reliable cooling performance. Their significance continues to grow as industries demand energy-efficient solutions to meet evolving environmental standards.

- The wire tube condenser market, valued at $3.5 billion in 2023, is projected to reach $5.7 billion by 2032.

- A compound annual growth rate (CAGR) of 6.2% from 2024 to 2032 highlights their increasing importance in refrigeration applications.

Reliable Wire Tube Condenser Manufacturers play a pivotal role in meeting these demands by delivering durable, high-quality products that support large-scale operations and sustainable practices.

Key Takeaways

- Wire tube condensers help move heat in cooling systems.

- The market for these condensers is growing fast, reaching $5.7 billion by 2032.

- Picking a reliable maker is important; check their history and certifications.

- Good condensers work better and last longer, saving money over time.

- New designs, like MicroGroove, make heat transfer much more effective.

- A company with a good reputation is likely trustworthy and makes quality products.

- Great customer service can reduce delays and make products last longer.

- Choose manufacturers by checking their certifications, product quality, and reviews.

Criteria for Selection

Reliability

Reliability remains a cornerstone in selecting wire tube condenser manufacturers. Industrial refrigeration systems demand components that perform consistently under varying conditions. Manufacturers with proven track records in delivering durable products gain a competitive edge. Companies that prioritize rigorous quality control processes and adhere to international standards, such as ISO9001 certifications, demonstrate their commitment to reliability.

Long-term partnerships with global brands further validate a manufacturer's dependability. For instance, manufacturers like Ningbo Taojun Refrigeration Equipment Co., Ltd. have established collaborations with industry leaders such as Haier and Whirlpool. These partnerships highlight their ability to meet stringent requirements and deliver reliable solutions for large-scale operations.

Product Quality

High-quality wire tube condensers ensure optimal performance and longevity. Manufacturers that invest in advanced materials and precision engineering produce products capable of withstanding harsh industrial environments. Features such as corrosion-resistant coatings and enhanced structural designs contribute to superior product quality.

Customer satisfaction often correlates with product quality. Companies that consistently deliver condensers with minimal defects and high efficiency earn trust within the industry. Certifications like the EU ROHS environmental directive and UL certification further underscore a manufacturer's commitment to quality. These standards ensure compliance with environmental and safety regulations, making their products suitable for diverse applications.

Innovation and Technology

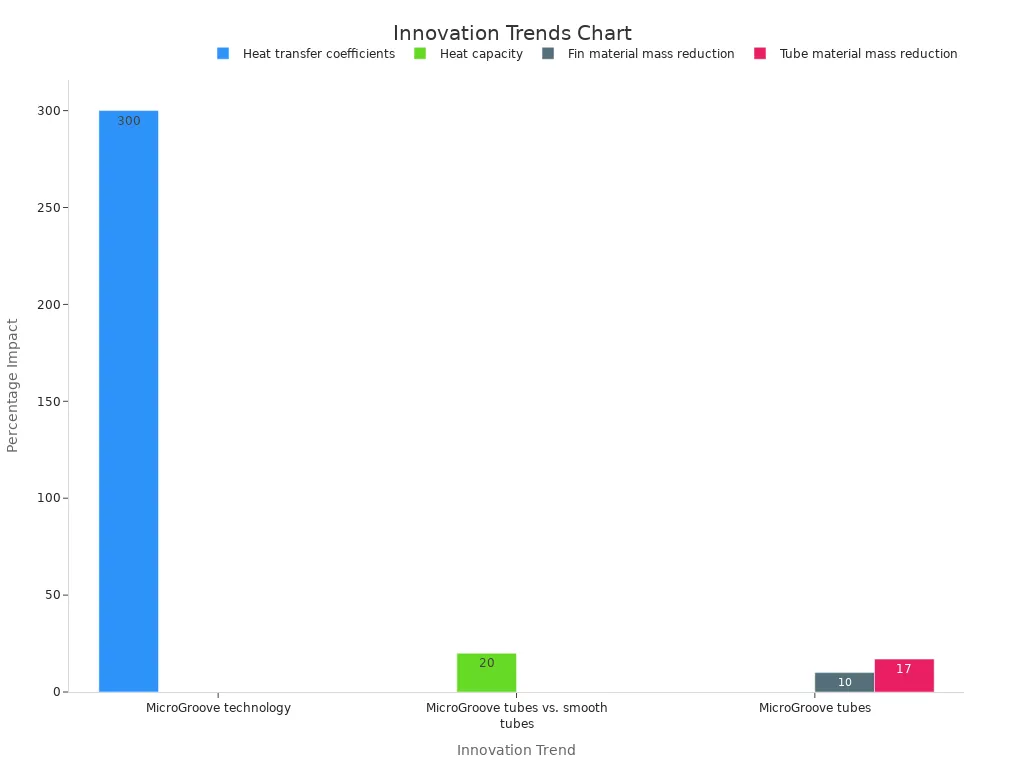

Technological advancements drive the evolution of wire tube condensers. Manufacturers that embrace innovation improve efficiency and reduce operational costs for their clients. Emerging technologies, such as MicroGroove tube designs, significantly enhance heat transfer coefficients by up to 300%. These tubes also reduce material mass, with fin material decreasing by up to 10% and tube material by 17%.

Other innovations include pressure expansion technology for tube and fin joining, which ensures structural integrity during manufacturing. Enhanced surface designs further improve heat transfer characteristics, making condensers more efficient. Manufacturers that integrate these advancements into their production processes position themselves as leaders in the industry.

By prioritizing reliability, product quality, and innovation, manufacturers can meet the growing demands of industrial refrigeration systems while maintaining their competitive edge in the market.

Market Reputation

Market reputation plays a pivotal role in determining the credibility of wire tube condenser manufacturers. Companies with a strong reputation often demonstrate consistent performance, high-quality products, and excellent customer relationships. A positive reputation reflects years of dedication to meeting industry standards and exceeding client expectations.

Manufacturers like Ningbo Taojun Refrigeration Equipment Co., Ltd. have built a solid reputation by collaborating with globally recognized brands such as Haier, Midea, and Whirlpool. These partnerships highlight their ability to deliver reliable solutions for large-scale industrial refrigeration systems. Additionally, their adherence to certifications like ISO9001 and UL further strengthens their standing in the market.

Tip: A manufacturer’s reputation can often be gauged by their client portfolio, industry certifications, and customer testimonials.

Word-of-mouth recommendations and online reviews also contribute significantly to a company’s market image. Businesses that prioritize transparency and maintain open communication with their clients often enjoy higher trust levels. For instance, companies that actively engage in trade shows, industry events, and technical seminars showcase their expertise and commitment to innovation. This proactive approach enhances their visibility and reinforces their reputation as industry leaders.

Customer Support and After-Sales Service

Customer support and after-sales service are critical factors when evaluating wire tube condenser manufacturers. These services ensure that clients receive timely assistance, minimizing downtime and operational disruptions. Manufacturers that prioritize customer satisfaction often provide comprehensive support, including installation guidance, troubleshooting, and maintenance services.

Top manufacturers, such as Ningbo Taojun Refrigeration Equipment Co., Ltd., excel in this area by offering tailored solutions to meet diverse client needs. Their commitment to after-sales service is evident in their long-standing partnerships with international brands. By addressing customer concerns promptly and effectively, they foster trust and loyalty.

Note: Reliable after-sales service can significantly reduce operational costs by preventing equipment failures and extending product lifespan.

Many manufacturers also invest in training programs for their clients. These programs educate users on proper equipment handling and maintenance, ensuring optimal performance. Additionally, some companies provide online resources, such as user manuals, FAQs, and video tutorials, to assist customers remotely. This multi-channel approach to customer support enhances accessibility and convenience.

Top 10 Wire Tube Condenser Manufacturers

Manufacturer 1: Schutte & Koerting

Company Overview

Schutte & Koerting (S&K) has been a prominent name in the industrial refrigeration sector for over a century. Established in 1876, the company specializes in designing and manufacturing high-performance heat transfer equipment, including wire tube condensers. Headquartered in Pennsylvania, USA, S&K serves a global clientele across industries such as food processing, pharmaceuticals, and petrochemicals. Its commitment to engineering excellence and customer satisfaction has solidified its reputation as a trusted partner in the refrigeration industry.

Key Product Details and Technical Specifications

S&K's wire tube condensers are engineered for durability and efficiency. These products feature corrosion-resistant materials, ensuring longevity in harsh industrial environments. The condensers utilize advanced fin designs to maximize heat transfer efficiency, reducing energy consumption by up to 15%. Additionally, S&K offers customizable options to meet specific client requirements, including varying tube diameters and fin spacing. The company adheres to international standards, such as ASME and ISO9001, ensuring consistent quality across its product range.

Application Scenarios

S&K's wire tube condensers are widely used in industrial refrigeration systems requiring robust and reliable cooling solutions. Common applications include cold storage facilities, chemical processing plants, and large-scale food production units. Their ability to perform under extreme conditions makes them ideal for industries with stringent operational demands.

Pros and Cons

-

Pros:

- High energy efficiency.

- Customizable designs for diverse applications.

- Strong adherence to international quality standards.

-

Cons:

- Limited availability in certain regions.

Manufacturer 2: Baltimore Aircoil Company

Company Overview

Baltimore Aircoil Company (BAC) is a global leader in heat transfer and thermal storage solutions. Founded in 1938, BAC operates in over 100 countries, providing innovative cooling technologies for industrial and commercial applications. The company is headquartered in Maryland, USA, and is renowned for its focus on sustainability and energy efficiency. BAC's extensive product portfolio includes wire tube condensers designed to meet the evolving needs of modern refrigeration systems.

Key Product Details and Technical Specifications

BAC's wire tube condensers incorporate cutting-edge technology to deliver superior performance. The products feature MicroGroove tube designs, which enhance heat transfer efficiency by up to 300%. This innovation reduces material usage, contributing to cost savings and environmental sustainability. BAC also employs advanced pressure expansion techniques to ensure structural integrity during manufacturing. The condensers are available in various configurations, catering to both standard and custom requirements.

Application Scenarios

BAC's wire tube condensers are ideal for applications requiring high efficiency and reliability. These include data centers, pharmaceutical manufacturing, and large-scale HVAC systems. Their compact design and lightweight construction make them suitable for installations with space constraints.

Pros and Cons

-

Pros:

- Exceptional heat transfer efficiency.

- Environmentally friendly manufacturing processes.

- Extensive global distribution network.

-

Cons:

- Higher initial investment compared to competitors.

Manufacturer 3: Tecumseh Products Company LLC

Company Overview

Tecumseh Products Company LLC has been a pioneer in refrigeration and air conditioning solutions since its inception in 1934. Based in Michigan, USA, the company serves a diverse range of industries, including retail, healthcare, and food service. Tecumseh's dedication to innovation and quality has earned it a strong position among leading wire tube condenser manufacturers.

Key Product Details and Technical Specifications

Tecumseh's wire tube condensers are designed for optimal performance and cost-effectiveness. The company employs advanced manufacturing techniques to produce condensers with high thermal efficiency and durability. A comparative analysis highlights Tecumseh's competitive edge in production volume and gross margin:

| Metric | Tecumseh Products | Competitor A | Competitor B |

|---|---|---|---|

| Production Volume | High | Medium | Low |

| Value | $X million | $Y million | $Z million |

| Price | Competitive | Higher | Lower |

| Gross Margin | 25% | 20% | 15% |

These condensers are available in various sizes and configurations, making them suitable for a wide range of applications. Tecumseh also ensures compliance with international standards, including UL and ROHS certifications.

Application Scenarios

Tecumseh's wire tube condensers are widely used in commercial refrigeration systems, such as supermarket display cases and beverage coolers. Their robust design and high efficiency make them suitable for demanding environments, including healthcare facilities and industrial kitchens.

Pros and Cons

-

Pros:

- High production capacity ensures consistent supply.

- Competitive pricing without compromising quality.

- Strong focus on innovation and efficiency.

-

Cons:

- Limited customization options for niche applications.

Manufacturer 4: Copeland LP

Company Overview

Copeland LP, a division of Emerson Electric Co., has been a leader in the refrigeration and HVAC industry for decades. Headquartered in Missouri, USA, the company specializes in innovative cooling solutions, including wire tube condensers. Copeland LP is renowned for its commitment to energy efficiency and sustainability, aligning with global environmental standards. Its products are widely used across various industries, including food processing, pharmaceuticals, and commercial refrigeration.

Key Product Details and Technical Specifications

Copeland LP's wire tube condensers are designed to deliver exceptional performance and durability. These condensers feature advanced corrosion-resistant coatings, ensuring longevity in harsh environments. The company employs precision engineering to optimize heat transfer efficiency, reducing energy consumption by up to 20%. Additionally, Copeland LP offers customizable options, such as varying tube diameters and fin configurations, to meet specific client needs. All products comply with international standards, including ISO9001 and UL certifications, guaranteeing consistent quality.

Application Scenarios

Copeland LP's wire tube condensers are ideal for applications requiring reliable and efficient cooling solutions. Common use cases include cold storage facilities, supermarket refrigeration systems, and industrial food processing units. Their robust design and high efficiency make them suitable for demanding environments where consistent performance is critical.

Pros and Cons

-

Pros:

- High energy efficiency and durability.

- Customizable designs for diverse applications.

- Strong adherence to international quality standards.

-

Cons:

- Limited availability in certain regions.

Manufacturer 5: Evapco, Inc.

Company Overview

Evapco, Inc., founded in 1976, is a global leader in heat transfer solutions. Based in Maryland, USA, the company operates in over 50 countries, providing innovative cooling technologies for industrial and commercial applications. Evapco's focus on sustainability and energy efficiency has earned it a strong reputation among wire tube condenser manufacturers. Its extensive product portfolio caters to a wide range of industries, including data centers, healthcare, and food processing.

Key Product Details and Technical Specifications

Evapco's wire tube condensers incorporate cutting-edge technology to enhance performance and reliability. These products feature MicroGroove tube designs, which improve heat transfer efficiency by up to 300%. The condensers are constructed using lightweight, corrosion-resistant materials, reducing installation costs and extending product lifespan. Evapco also employs advanced manufacturing techniques, such as pressure expansion technology, to ensure structural integrity. The company offers a variety of configurations to meet both standard and custom requirements.

Application Scenarios

Evapco's wire tube condensers are widely used in applications requiring high efficiency and reliability. These include large-scale HVAC systems, pharmaceutical manufacturing, and cold storage facilities. Their compact design and lightweight construction make them suitable for installations with space constraints.

Pros and Cons

-

Pros:

- Exceptional heat transfer efficiency.

- Environmentally friendly manufacturing processes.

- Extensive global distribution network.

-

Cons:

- Higher initial investment compared to competitors.

Manufacturer 6: Colmac Coil

Company Overview

Colmac Coil, established in 1971, is a leading manufacturer of heat transfer equipment, including wire tube condensers. Headquartered in Washington, USA, the company serves a global clientele across industries such as food processing, petrochemicals, and industrial refrigeration. Colmac Coil is known for its innovative approach to product design and its commitment to delivering high-quality, energy-efficient solutions.

Key Product Details and Technical Specifications

Colmac Coil's wire tube condensers are engineered for maximum efficiency and durability. The company uses advanced materials, such as stainless steel and aluminum, to ensure resistance to corrosion and wear. Its condensers feature enhanced fin designs that optimize heat transfer, reducing energy consumption by up to 15%. Colmac Coil also offers customizable options, including different tube diameters and fin spacing, to cater to specific client requirements. All products meet international standards, such as ASME and ISO9001, ensuring consistent quality.

Application Scenarios

Colmac Coil's wire tube condensers are ideal for industrial refrigeration systems requiring robust and reliable cooling solutions. Common applications include cold storage warehouses, chemical processing plants, and large-scale food production facilities. Their ability to perform under extreme conditions makes them a preferred choice for industries with stringent operational demands.

Pros and Cons

-

Pros:

- High energy efficiency and durability.

- Customizable designs for diverse applications.

- Strong adherence to international quality standards.

-

Cons:

- Limited product availability in certain regions.

Manufacturer 7: Comforplanet

Company Overview

Comforplanet has established itself as a trusted name in the refrigeration industry. Based in China, the company specializes in manufacturing high-quality wire tube condensers and other refrigeration components. With a focus on innovation and customer satisfaction, Comforplanet has built a strong presence in both domestic and international markets. Its commitment to delivering reliable and efficient products has earned it a reputation as one of the leading wire tube condenser manufacturers in the industry.

Key Product Details and Technical Specifications

Comforplanet's wire tube condensers are designed to meet the demands of modern industrial refrigeration systems. These condensers feature advanced materials that enhance durability and resistance to corrosion. The company employs precision engineering to optimize heat transfer efficiency, ensuring consistent performance in challenging environments.

Key specifications include:

- Material: High-grade copper and aluminum for superior thermal conductivity.

- Design: Compact and lightweight, suitable for space-constrained installations.

- Efficiency: Enhanced fin designs that reduce energy consumption by up to 12%.

- Certifications: Compliance with ISO9001 and CE standards, ensuring quality and safety.

Application Scenarios

Comforplanet's wire tube condensers are widely used in various industrial applications. These include cold storage facilities, commercial refrigeration units, and HVAC systems. Their compact design makes them ideal for installations where space is limited. Additionally, their robust construction ensures reliable performance in environments with high humidity or temperature fluctuations.

Pros and Cons

-

Pros:

- High thermal efficiency and durability.

- Compact design suitable for diverse applications.

- Strong adherence to international quality standards.

-

Cons:

- Limited customization options for niche industries.

Manufacturer 8: Ningbo Taojun Refrigeration Equipment Co., Ltd.

Company Overview

Ningbo Taojun Refrigeration Equipment Co., Ltd., located in Xiangshan, Ningbo, has been a prominent player in the refrigeration industry since its establishment in 1988. Originally known as Xiangshan Refrigeration Accessories Factory of Zhejiang University, the company has evolved into a comprehensive enterprise. It integrates design, production, sales, and after-sales service for refrigeration accessories.

The company’s flagship brand, "Taojun," is synonymous with quality and innovation. Over the years, it has partnered with leading global brands like Haier, Midea, and Whirlpool. Its products are exported to Europe, America, Southeast Asia, and other regions, solidifying its position as a global leader among wire tube condenser manufacturers.

Key Product Details and Technical Specifications

Ningbo Taojun offers a diverse range of wire tube condensers designed for industrial and commercial applications. These products are known for their reliability, efficiency, and compliance with international standards.

Key features include:

- Material: Corrosion-resistant copper and brass for extended lifespan.

- Design: Innovative tube and fin configurations that enhance heat transfer.

- Efficiency: Reduced energy consumption through advanced engineering.

- Certifications: ISO9001, EU ROHS, and UL certifications, ensuring compliance with global standards.

Application Scenarios

Ningbo Taojun's wire tube condensers are ideal for large-scale refrigeration systems. Common applications include supermarket refrigeration units, industrial cooling systems, and HVAC installations. Their robust design and high efficiency make them suitable for demanding environments, such as food processing plants and pharmaceutical facilities.

Pros and Cons

-

Pros:

- Strong focus on innovation and quality.

- Extensive global distribution network.

- Long-standing partnerships with leading brands.

-

Cons:

- Higher initial investment compared to some competitors.

Manufacturer 9: Ningbo Combine Refrigeration Equipment Co., Ltd.

Company Overview

Ningbo Combine Refrigeration Equipment Co., Ltd. is a leading manufacturer of refrigeration components, including wire tube condensers. Based in Ningbo, China, the company has gained recognition for its commitment to quality and customer satisfaction. With a focus on research and development, Ningbo Combine continuously improves its product offerings to meet the evolving needs of the refrigeration industry.

The company serves a diverse clientele, ranging from small businesses to large industrial enterprises. Its dedication to delivering reliable and efficient solutions has positioned it as a key player among wire tube condenser manufacturers.

Key Product Details and Technical Specifications

Ningbo Combine's wire tube condensers are designed to deliver optimal performance and durability. The company uses advanced manufacturing techniques to ensure consistent quality across its product range.

Key specifications include:

- Material: High-quality copper and aluminum for enhanced thermal conductivity.

- Design: Modular configurations that allow for easy installation and maintenance.

- Efficiency: Improved heat transfer efficiency through innovative fin designs.

- Certifications: Compliance with ISO9001 and CE standards, ensuring reliability and safety.

Application Scenarios

Ningbo Combine's wire tube condensers are suitable for a wide range of applications. These include commercial refrigeration systems, industrial cooling units, and HVAC installations. Their modular design makes them easy to install and maintain, reducing downtime and operational costs.

Pros and Cons

-

Pros:

- High-quality materials and construction.

- Modular design for easy installation and maintenance.

- Strong focus on customer satisfaction.

-

Cons:

- Limited availability in certain regions.

Manufacturer 10: Zhejiang Kangsheng Co., Ltd.

Company Overview

Zhejiang Kangsheng Co., Ltd. has been a prominent name in the refrigeration industry for decades. Headquartered in Zhejiang Province, China, the company specializes in manufacturing high-quality wire tube condensers and other refrigeration components. Kangsheng has built a reputation for its commitment to innovation, quality, and customer satisfaction. Its products are widely recognized for their reliability and efficiency, making the company a trusted partner for industrial refrigeration systems worldwide.

Kangsheng actively invests in research and development to stay ahead of industry trends. Its focus on sustainable manufacturing practices aligns with global environmental standards. The company serves a diverse clientele, including businesses in food processing, pharmaceuticals, and commercial refrigeration. Kangsheng's dedication to excellence has earned it certifications such as ISO9001 and CE, further solidifying its position among leading Wire Tube Condenser Manufacturers.

Key Product Details and Technical Specifications

Kangsheng's wire tube condensers are designed to deliver exceptional performance and durability. The company uses advanced materials, such as corrosion-resistant copper and aluminum, to ensure longevity in demanding environments. Its products feature innovative fin designs that optimize heat transfer efficiency, reducing energy consumption by up to 18%.

Key specifications include:

- Material: High-grade copper and aluminum for superior thermal conductivity.

- Design: Compact and modular configurations for easy installation.

- Efficiency: Enhanced heat transfer capabilities through precision engineering.

- Certifications: Compliance with ISO9001 and CE standards, ensuring reliability and safety.

Kangsheng also offers customizable options to meet specific client requirements. These include varying tube diameters, fin spacing, and coating materials. The company's commitment to quality control ensures consistent performance across its product range.

Application Scenarios

Kangsheng's wire tube condensers are suitable for a wide range of industrial applications. Common use cases include cold storage facilities, supermarket refrigeration systems, and HVAC installations. Their robust construction makes them ideal for environments with high humidity or temperature fluctuations.

In food processing plants, Kangsheng's condensers ensure reliable cooling for perishable goods. Pharmaceutical facilities benefit from their precision engineering, which maintains consistent temperatures for sensitive products. Additionally, their compact design allows for easy integration into commercial refrigeration units, reducing installation time and costs.

Tip: Kangsheng's modular designs simplify maintenance, minimizing downtime and operational disruptions.

Pros and Cons

-

Pros:

- High thermal efficiency and durability.

- Modular design for easy installation and maintenance.

- Strong adherence to international quality standards.

- Customizable options for diverse applications.

-

Cons:

- Limited availability in certain regions.

Comparison Table

Key Features

Each manufacturer offers unique features that cater to diverse industrial refrigeration needs. Below is a summary of the key attributes of the top 10 manufacturers:

| Manufacturer | Key Features | Certifications | Innovation Level |

|---|---|---|---|

| Schutte & Koerting | Corrosion-resistant materials, customizable designs, advanced fin technology | ISO9001, ASME | High |

| Baltimore Aircoil Company (BAC) | MicroGroove tube designs, pressure expansion technology, eco-friendly manufacturing | ISO9001, CE | Very High |

| Tecumseh Products Company LLC | High thermal efficiency, competitive pricing, robust production capacity | UL, ROHS | Moderate |

| Copeland LP | Precision engineering, corrosion-resistant coatings, energy-efficient designs | ISO9001, UL | High |

| Evapco, Inc. | Lightweight materials, compact designs, MicroGroove technology | ISO9001, CE | Very High |

| Colmac Coil | Stainless steel construction, enhanced fin designs, customizable configurations | ISO9001, ASME | High |

| Comforplanet | Compact and lightweight designs, high-grade copper materials, energy-efficient fin technology | ISO9001, CE | Moderate |

| Ningbo Taojun Refrigeration | Corrosion-resistant copper, innovative tube-fin configurations, global distribution network | ISO9001, ROHS, UL | High |

| Ningbo Combine Refrigeration | Modular configurations, advanced thermal conductivity, easy installation | ISO9001, CE | Moderate |

| Zhejiang Kangsheng Co., Ltd. | Modular designs, precision engineering, customizable options | ISO9001, CE | High |

Tip: Manufacturers with certifications like ISO9001 and UL ensure compliance with international quality and safety standards.

Strengths and Weaknesses

The strengths and weaknesses of each manufacturer highlight their suitability for specific applications.

-

Strengths:

- Schutte & Koerting: High durability and customizable designs.

- BAC: Exceptional heat transfer efficiency and sustainability focus.

- Tecumseh: Cost-effective solutions with high production capacity.

- Copeland LP: Energy-efficient and corrosion-resistant products.

- Evapco: Lightweight, compact designs with advanced technology.

- Colmac Coil: Robust construction and customizable options.

- Comforplanet: Compact designs and high thermal efficiency.

- Ningbo Taojun: Strong global presence and innovative designs.

- Ningbo Combine: Easy-to-install modular configurations.

- Zhejiang Kangsheng: Customizable and precision-engineered products.

-

Weaknesses:

- Some manufacturers, such as BAC and Evapco, may have higher initial costs.

- Limited regional availability affects companies like Schutte & Koerting and Colmac Coil.

Note: While some manufacturers have higher upfront costs, their energy-efficient designs often result in long-term savings.

Application Suitability

The suitability of each manufacturer depends on the specific requirements of industrial refrigeration systems.

- High-Efficiency Applications: BAC, Evapco, and Copeland LP excel in environments requiring maximum energy efficiency, such as data centers and pharmaceutical facilities.

- Cost-Effective Solutions: Tecumseh and Comforplanet provide affordable options for small to medium-scale operations.

- Customizable Designs: Schutte & Koerting, Colmac Coil, and Zhejiang Kangsheng offer tailored solutions for niche industries.

- Global Reach: Ningbo Taojun and Ningbo Combine cater to international markets, making them ideal for multinational enterprises.

Callout: Evaluate your operational needs and budget constraints to select the most suitable manufacturer for your application.

Selecting reliable wire tube condenser manufacturers is crucial for ensuring the efficiency and durability of industrial refrigeration systems. Each manufacturer listed in this blog offers unique strengths, making it essential for businesses to evaluate their specific operational requirements before making a decision. Factors such as product quality, innovation, and customer support should guide this evaluation process.

Quality and innovation play a pivotal role in achieving long-term performance. Advanced designs and cutting-edge technologies not only enhance energy efficiency but also reduce operational costs. By prioritizing these aspects, businesses can ensure sustainable and reliable refrigeration solutions.

FAQ

### What is a wire tube condenser, and why is it important?

A wire tube condenser is a heat exchange device used in refrigeration systems. It transfers heat from the refrigerant to the surrounding air, ensuring efficient cooling. Its importance lies in its ability to maintain optimal system performance and energy efficiency.

### How do I choose the right wire tube condenser manufacturer?

Evaluate manufacturers based on product quality, certifications, innovation, and customer support. Consider their reputation and partnerships with global brands. Look for companies that offer energy-efficient designs and comply with international standards like ISO9001 and UL.

### Are wire tube condensers suitable for all industrial applications?

Wire tube condensers are versatile and used in various industries, including food processing, pharmaceuticals, and HVAC systems. However, their suitability depends on specific operational requirements, such as cooling capacity, environmental conditions, and space constraints.

### What certifications should I look for in a wire tube condenser?

Key certifications include ISO9001 for quality management, UL for safety compliance, and ROHS for environmental standards. These certifications ensure the product meets global quality, safety, and sustainability benchmarks.

### How does innovation impact wire tube condenser performance?

Innovations like MicroGroove tube designs and advanced fin configurations enhance heat transfer efficiency. These advancements reduce energy consumption and operational costs, making the condensers more effective and environmentally friendly.

### What role does customer support play in selecting a manufacturer?

Customer support ensures timely assistance with installation, maintenance, and troubleshooting. Reliable after-sales service minimizes downtime and extends product lifespan, making it a critical factor in manufacturer selection.

### Can wire tube condensers be customized for specific needs?

Yes, many manufacturers offer customizable options, such as varying tube diameters, fin spacing, and materials. Customization ensures the condenser meets unique operational demands and integrates seamlessly into existing systems.

### What are the benefits of choosing a globally recognized manufacturer?

Global manufacturers often have extensive experience, advanced technologies, and robust quality control processes. Their products are widely tested and trusted, ensuring reliability and compatibility with international standards.

Tip: Always assess your operational needs and consult with manufacturers to find the best solution for your application.