Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

Say goodbye to supply chain anxiety: How do we ensure stable and on-time deliveries of line tube condensers to our European customers?

A comprehensive strategy ensures the stable and on-time delivery of Wire Tube Condenser products to European customers. This multi-faceted approach focuses on cultivating robust supplier relationships and optimizing logistics operations. It also incorporates proactive risk management protocols and advanced technological integration. These combined strategies effectively eliminate supply chain anxiety, guaranteeing consistent reliability for your business operations.

Key Takeaways

- We build strong relationships with many suppliers. This helps us always have enough materials for wire tube condensers.

- We make our factories work very well. We keep extra parts ready. This helps us make wire tube condensers on time.

- We plan how to ship products across Europe. We use the best ways to send them. This makes sure they arrive on time.

- We watch our supply chain closely. We plan for problems before they happen. This keeps deliveries smooth and on schedule.

Building Resilient Supplier Relationships for Consistent Wire Tube Condenser Supply

<<<START_SECTION_CONTENT>>>

Building Resilient Supplier Relationships for Consistent Wire Tube Condenser Supply

Strategic Sourcing and Diversification of Raw Materials for Wire Tube Condensers

Strategic sourcing forms the foundation of a stable supply chain. We prioritize identifying and qualifying new raw material suppliers across various geographic regions. This process involves a structured and targeted approach, often utilizing pre-approved lists and procurement databases. AI-driven supplier data platforms significantly reduce the time required to identify potential suppliers, sometimes by 90% or more. These platforms, like Veridion, provide access to a global supplier database, updated weekly through AI-driven algorithms. Users can enter search criteria in natural language to quickly get results, refining the list by adding more criteria and risk factors. Market intelligence allows for benchmarking suppliers against similar market players. Diversification reduces dependency on single suppliers, minimizing risks from disruptions. It enhances delivery efficiency and cost management. We always advocate for a diversified approach to ensure stable procurement and operational resilience.

Long-Term Contracts and Collaborative Forecasting for Wire Tube Condensers

Long-term contracts with suppliers are crucial for supply stability and cost predictability. These agreements often lead to cost reductions through bulk purchasing and stable pricing. Suppliers may offer discounts for assured, consistent business. For example, a steel manufacturer with a long-term agreement might benefit from lower per-unit costs due to volume commitments. These contracts provide operational stability, enabling better financial planning and uninterrupted supply. This includes predictable costs through fixed or predictable pricing, simplifying budgeting, and consistent supply to ensure businesses meet customer demands without interruptions. Long-term agreements also significantly reduce indirect labor by minimizing the need for frequent RFQs, purchase orders, and price negotiations.

Quality Control and Performance Monitoring at Source for Wire Tube Condensers

Effective quality control methodologies ensure component quality directly at the supplier's manufacturing site. We implement rigorous inspection processes, visually checking raw materials, in-process items, and finished products for defects or deviations. This helps identify problems early. Statistical Process Control (SPC) uses statistical tools to monitor and control processes by collecting data from different production stages. Control charts track variations, and corrective action is taken if processes go beyond acceptable limits. Quality audits review company processes and products for compliance with quality standards, assessing everything from raw materials to finished goods. Findings lead to improvements in procedures and policies. Poor quality control leads to defective products that necessitate recalls, disrupting inventory cycles and increasing warehousing costs. Investing in quality control services is a strategic financial pillar that helps businesses safeguard capital and ensure compliance.

Optimizing Production and Inventory Management for Predictable Wire Tube Condenser Output

<<<START_SECTION_CONTENT>>>

Optimizing Production and Inventory Management for Predictable Wire Tube Condenser Output

Lean Manufacturing Principles and Production Efficiency for Wire Tube Condensers

Optimizing production processes is fundamental for predictable output. We implement lean manufacturing principles to enhance efficiency and minimize waste. These principles focus on continuous improvement and value creation. For instance, Poka-Yoke fixtures prevent assembly errors, significantly reducing defect rates. A medical device manufacturer successfully cut defect rates by 75% and saved $2 million annually by using Poka-Yoke. Value Stream Mapping helps identify and eliminate non-value-added activities. An auto parts supplier, after mapping their value stream, discovered 60% of production time was waste. They cut lead time from 23 days to 5 days by adopting new cell layouts and Kanban cards.

Lean tools offer diverse benefits:

| Tool Category | Primary Focus | Key Benefits | Best For |

|---|---|---|---|

| Quality | Defect prevention | Lower scrap/rework | High-precision work |

| Flow | Smooth operations | Reduced lead time | Complex processes |

| Productivity | Resource efficiency | Higher output | Labor-intensive work |

| Engagement | Worker innovation | Continuous improvement | All operations |

Other effective lean techniques include Just-In-Time (JIT) for inventory reduction, Kaizen for continuous improvement through employee suggestions, and Kanban for regulating material flow. Toyota's paint lines use Jidoka to detect defects instantly, preventing thousands in rework costs. A metal fabricator's 5S program resulted in 50% less motion waste and a 30% productivity gain. These methods collectively streamline operations, ensuring consistent quality and output for products like the Wire Tube Condenser. Industry studies show 95% of companies implementing lean manufacturing experience at least a 20% increase in productivity.

Strategic Inventory Buffers and Safety Stock for Wire Tube Condensers

Maintaining strategic inventory buffers and safety stock is critical for mitigating supply chain disruptions. Unpredictable demand fluctuations can lead to overproduction, underproduction, or stockouts. These buffers act as a safeguard against unforeseen delays in raw material delivery or sudden spikes in customer orders. They ensure a continuous flow of production and prevent costly interruptions. For example, if a supplier experiences an unexpected delay, adequate safety stock prevents production lines from halting. This strategy minimizes the risk of inventory losses and obsolescence, which can arise from extended timelines between production and distribution. By carefully calculating and maintaining optimal buffer levels, we ensure consistent product availability without incurring excessive holding costs. This proactive approach supports stable production schedules and reliable delivery commitments.

Advanced Production Planning and Scheduling Systems for Wire Tube Condenser Deliveries

Advanced Production Planning and Scheduling (APS) systems are indispensable for managing complex manufacturing environments. These systems create optimized schedules that balance production efficiency with delivery performance. They maximize output on bottleneck resources, directly increasing revenue. APS solutions synchronize supply with demand, effectively reducing inventory levels. They provide company-wide visibility into capacity, enabling data-driven decision-making.

Key features of these systems include:

- Advanced planning functionality: This considers forecasts and long-term orders. It supports decisions on feasibility, workforce extension, resource capacity, and factory utilization. It determines what, how much, where, and when to make products, along with required resources.

- Advanced scheduling functionality: This considers resource availability and additional constraints like tooling and materials. It creates an accurate model of the manufacturing environment. It uses intelligent built-in rules for scheduling and supports decision-making for overtime, order prioritization, split production batches, and due date negotiation.

Implementing advanced production planning software yields significant returns. It can increase throughput by up to 20% and reduce rework by up to 50%. These improvements lead to more profitable production processes and increased customer satisfaction. Manes Machine, a manufacturer of complex aerospace components, significantly improved efficiency and profitability by implementing an advanced scheduling system. This system provided enhanced visibility, optimized resource allocation, and reduced lead times. It allowed them to calculate a measurable ROI, justifying further technology investments. A manufacturer investing $100,000 in such software can achieve a 50% ROI through annual cost savings and increased revenue.

<<<END_SECTION_CONTENT>>>

Streamlining Logistics and Distribution for On-Time European Wire Tube Condenser Deliveries

Multi-Modal Transportation Strategies for Wire Tube Condensers

Efficient logistics are crucial for timely deliveries to European customers. International logistics often face several bottlenecks. Inaccurate customs documents, for example, create delays due to post-Brexit complexities and paperwork errors. Driving bans and restrictions, including varying regulations, public holidays, curfews, and vehicle size/weight limits across European countries, also impact product journeys. Furthermore, goods risk damage during transport from movement, emergency braking, or poor road conditions. Shipping disruptions and input shortages also present significant challenges in global supply chains. A surge in demand for products like electronics, coupled with events such as port outbreaks, plant accidents, and adverse weather, leads to bottlenecks in the transport sector. This demand-supply imbalance results in unprecedented lengthening of suppliers' delivery times. Euro area and EU countries are particularly affected by these shipping and input-related bottlenecks. Worsening port congestion at key gateways in northern Europe, including Bremerhaven, Antwerp, Hamburg, Rotterdam, and Felixstowe, further complicates matters. Labor shortages also hinder barge traffic to and from inland locations, and low water levels on the Rhine River impede barge traffic.

We carefully select the optimal combination of transportation modes for international shipments. This ensures efficient and reliable delivery of our Wire Tube Condenser products. Several factors guide this selection:

- Cost of Transport: Budget is a primary consideration. Transport costs influence the final sale price. Factors like volume, weight, urgency, and perishability affect cost. Water transport is generally the most cost-effective for bulky, heavy goods over long distances when time is not critical. Rail is also inexpensive for such goods. Road transport offers savings on handling and packaging for shorter distances. Air transport is the most expensive but fastest, suitable for perishable, fragile, and valuable goods. Hidden costs like insurance and finance charges also require consideration.

- Reliability and Regularity of Service: The urgency and speed required for delivery influence the choice. All modes (land, ocean, air) can experience adverse weather, causing delays.

- Safety: The security of goods in transit is crucial. Land transport is often preferred over rail due to fewer losses. Sea transport is considered the riskiest due to exposure to sea perils and long travel durations. Special facilities like refrigeration or enhanced security measures may also be necessary.

- Characteristics of goods: The size, weight, fragility, danger level, and value of goods are key. Land and air transport suit fragile and small shipments, while rail and sea are better for heavy shipments. Air and land transport are optimal for breakable, fragile, and high-value products.

- Timescale: Air transport is best for urgent, speedy, long-distance transport, especially for perishable or fragile goods. Motor transport is faster than rail for short distances, but rail is faster and more economical for longer hauls. Water transport is generally unsuitable when time is a critical factor.

- Flexibility: Motor or road transport is the most flexible. It is not constrained by fixed schedules, routes, or flight/shipping times. It can operate at convenience and offers door-to-door delivery.

We consider cargo type and volume, urgency, budget, and location when choosing transportation methods.

- Large, heavy, or oversized goods typically go by ocean or rail.

- Lightweight, high-value, or perishable goods often travel by air.

- Frequent, small to medium shipments usually go by road.

- Urgent or time-sensitive deliveries require air transport.

- Non-urgent shipments can use ocean or rail.

- Flexible schedules and regional routes benefit from road transport.

- Ocean transport offers the lowest cost per unit internationally.

- Rail is cost-effective for bulk or long-haul inland freight.

- Road transport is affordable for short-haul or regional transport.

- Air transport is a premium option for the fastest delivery.

- Remote or landlocked areas often rely on air or road.

- Connections to ports or logistics hubs benefit from rail or road.

- International long-distance routes use ocean or air.

- Urban or industrial regions utilize rail or road.

The following table summarizes the key aspects of different transport modes:

| Factors | Ocean | Road | Air | Rail |

|---|---|---|---|---|

| Speed | Slowest (weeks) | Moderate (days) | Fastest (hours to days) | Moderate (days) |

| Cost | Lowest cost per unit (bulk, long-distance) | Economical (short/medium-distance) | Highest cost per unit (high-value or urgent) | Cost-effective (medium/long-distance bulk) |

| Capacity | Highest (large, heavy, bulky) | Moderate (flexible cargo sizes) | Lowest (limited by weight/size restrictions) | High (bulk commodities, containers) |

| Accessibility | Limited inland; requires road/rail integration | Highest; door-to-door service possible | Global reach; almost all international locations | Moderate; dependent on rail infrastructure |

| Distance | Ideal for long-distance, international shipments | Best for short to medium distances, regional or national | Best for international and very long distances urgently | Suitable for medium to long-distance inland transport |

| Reliability | Moderate; consistent schedules but affected by weather, port congestion, disruptions, etc. | Moderate; subject to traffic, weather, and road conditions | Highest; precise and strictly regulated schedules with minimal deviations | High; consistent scheduling, minimal disruptions, fewer delays than road |

| Flexibility | Low; limited by infrastructure, fixed routes, and schedules | Highest; easily adaptable routes and timings to adjust schedules | Moderate; typically relies on fixed routes and schedules with predictable timetables; option to charter for higher flexibility | Low; fixed routes and schedules with predictable timetables |

| Impact on climate | Reduced GHG emissions per unit transported compared to air freight | Significant GHG emissions, but high potential of improving with electric vehicles and use of renewable electricity | Significant GHG emissions, highest of all transport modes | Lowest GHG emissions on average for land transport compared to other options |

Strategic Warehousing and Distribution Hubs in Europe for Wire Tube Condensers

Strategic warehousing solutions in Europe offer international suppliers flexibility and control over inventory. This is crucial for financial and operational resilience, especially in response to tariffs. Solutions like transloading allow retailers to choose between direct distribution or temporary storage at intermediate warehouses. This helps mitigate uncertainty and enables quick responses to changes in demand, providing a strategic advantage in freight orchestration.

European warehousing strategies, particularly outsourcing to Third-Party Logistics (3PLs), significantly impact inventory costs. They shift costs from fixed to variable, which can improve EBITDA. However, this approach introduces variable pricing and potential hidden costs. These include long-term storage penalties, tech integration fees, and costs associated with switching or scaling providers. Understanding these cost mechanics is crucial for protecting margins and accurately forecasting profitability. Companies must weigh the trade-off between cost and control. They consider whether in-house control delivers measurable business value or if they are overpaying for a sense of control.

Outsourcing to 3PLs can also involve:

- Cost of stock discrepancies or delays: Inventory mismatches or fulfillment delays can lead to order cancellations, lost sales, and customer churn. This potentially incurs hourly service fees or additional reporting costs.

- Long-term storage penalties: Many providers charge double or triple the standard rate for inventory stored longer than agreed. This impacts profitability for slow-moving or seasonal products.

- Minimum monthly fees and volume commitments: Some providers require a minimum monthly spend (e.g., €50 – €200) or enforce volume commitments. This reduces flexibility and potentially hurts margins during slower periods.

- Tech integration fees or custom workflows: Custom ERP integrations, API connections, or reporting formats may come with one-time setup fees or ongoing maintenance costs. This requires upfront confirmation of all digital compatibility charges.

Customs Compliance and Documentation Expertise for Wire Tube Condenser Shipments

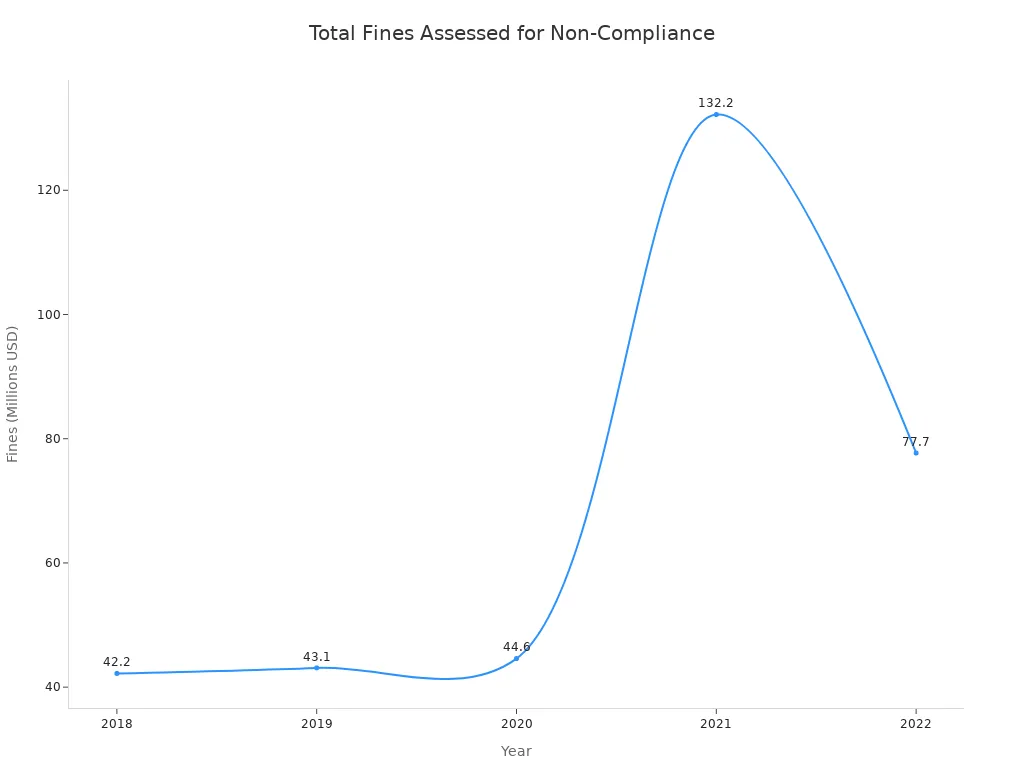

Strict adherence to customs regulations is paramount for smooth international shipments. Non-compliance can lead to severe penalties. Financial penalties and fines assessed by customs authorities are common. In severe cases of customs violations, corrective measures can include imprisonment. Incomplete or false customs declarations cause delays in shipments, as authorities may hold merchandise for inspection. Goods can also be seized due to inaccurate declarations, and seized products may incur liquidated damages. For severe instances of inaccurate declarations, legal action may be pursued. Non-compliance also hurts a business's reputation and leads to cash flow issues. Consistent failures to declare imported goods damage an importer's standing with customs authorities. This leads to more scrutiny and potential detention of future imports.

The financial impact of non-compliance can be substantial.

| Year | Total Fines Assessed in USD |

|---|---|

| 2018 | $42.2 million |

| 2019 | $43.1 million |

| 2020 | $44.6 million |

| 2021 | $132.2 million |

| 2022 | $77.7 million |

We maintain expert knowledge in customs compliance and documentation. This ensures all Wire Tube Condenser shipments meet regulatory requirements. Our team meticulously prepares all necessary paperwork, minimizing the risk of delays, fines, or seizures. This proactive approach safeguards our operations and ensures reliable delivery to our European customers.

Proactive Risk Management and Technology Integration for Wire Tube Condenser Deliveries

Real-Time Supply Chain Visibility and Tracking for Wire Tube Condensers

Real-time supply chain visibility is essential for proactive problem-solving. It provides instant access to critical information. This enables proactive decision-making instead of reactive responses. The system facilitates early identification of potential issues. These issues include weather events, supplier problems, or transportation delays. It identifies them before they impact operations. Companies achieve high on-time delivery rates, often 98% or more, by proactively managing the fulfillment process. They identify and correct potential delays through rerouting or expediting. This comprehensive visibility allows for faster responses to disruptions. It prevents minor issues from escalating into major crises. This maintains revenue and customer satisfaction. Basic visibility into key supply chain metrics allows businesses to automate processes. For example, they can monitor at-risk shipments. Knowing the location and estimated arrival of everything provides proactive notifications when a shipment is at risk. This allows teams to focus directly on resolving the issue. They do not spend time locating it.

Predictive Analytics for Demand and Supply Forecasting of Wire Tube Condensers

Predictive analytics significantly improves the accuracy of demand and supply forecasting. Traditional forecasting relies on static historical averages and rigid assumptions. This limits adaptability to sudden demand shifts or market disruptions. Predictive analytics uses real-time data. It considers seasonality, promotions, and external factors. This delivers responsive forecasts. Supply chain managers can match inventory to true demand. This reduces waste and ensures product availability. AI-driven forecasting in supply chain management can reduce errors by 20 to 50 percent. This leads to optimized inventory management. It dynamically adjusts thresholds based on consumption patterns, supplier lead times, and forecasts for products like the Wire Tube Condenser.

Contingency Planning and Emergency Protocols for Wire Tube Condenser Supply

Robust contingency planning is vital for mitigating disruptions. Manufacturers of industrial components face various risks. These include global events like political disruptions, trade disputes, and sanctions. Operational risks involve transportation failures, inventory issues, and supplier disruptions. Natural disasters such as extreme weather events also pose threats. Economic and financial risks, including market volatility and supplier instability, are also common. A comprehensive plan identifies potential risks. It analyzes their probability and impact. It outlines critical dependencies.

Key elements of a robust contingency plan include:

- Supplier Risk Management: Conduct thorough risk assessments for all critical suppliers. Understand potential disruptions and identify alternate suppliers.

- Inventory Management: Understand current stock levels and how long they would last during disruptions. Consider shifting from just-in-time (JIT) to just-in-case (JIC) inventory models.

- Robust Contracts: Ensure all agreements with suppliers are in writing. Include protective clauses for disruptions and force majeure conditions.

- Crisis Response Protocols: Define responsibilities and communication channels. Establish protocols for alternative supply chain routes or backup suppliers. Conduct regular simulation exercises.

We consistently ensure stable and on-time deliveries of Wire Tube Condenser to our European customers. Our integrated approach combines resilient supplier relationships, optimized production, streamlined logistics, and advanced risk management. This comprehensive commitment provides the reliability and peace of mind essential for your operations. It effectively eliminates supply chain anxiety.

FAQ

How does the company ensure the quality of raw materials for wire tube condensers?

The company implements rigorous quality control directly at the supplier's site. This includes visual inspections, Statistical Process Control (SPC), and regular quality audits. These methods identify and correct issues early, ensuring high-quality components from the start.

What production strategies guarantee predictable output for wire tube condensers?

The company uses lean manufacturing principles to boost efficiency and reduce waste. It also maintains strategic inventory buffers and safety stock. Advanced Production Planning and Scheduling (APS) systems optimize schedules, ensuring consistent output.

How does the company manage logistics for on-time European deliveries?

The company employs multi-modal transportation strategies, selecting optimal routes based on cost, speed, and cargo. Strategic warehousing in Europe and expert customs compliance ensure smooth, timely delivery.

What measures are in place to mitigate supply chain risks for wire tube condensers?

The company uses real-time supply chain visibility and predictive analytics for forecasting. Robust contingency planning and emergency protocols address potential disruptions. This proactive approach ensures supply chain resilience.