Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

Refrigerator Cooling Fan Motors: The Silent Heroes of Energy Efficiency

Refrigerator cooling Fan Motors play a pivotal role in maintaining optimal cooling performance. These motors efficiently circulate air, ensuring even temperature distribution and preventing hotspots. By reducing the strain on compressors, they significantly cut energy consumption and extend the lifespan of refrigeration systems. Studies have shown that optimized airflow can achieve remarkable energy savings, such as reducing annual electricity costs by up to20 million yen in large facilities. For businesses, investing in a high-quality refrigerator cooling fan motor for B2B procurement can lead to long-term cost savings and enhanced system reliability.

Key Takeaways

- Refrigerator fan motors are important for saving energy. They move air, keep temperatures steady, and lower energy bills.

- Buying good fan motors can save a lot of money. Businesses can cut electricity costs and make systems work better with energy-saving models.

- Taking care of fan motors is very important. Simple tasks like cleaning and checking parts can make them last longer and work well.

- Special motors, like DC variable speed motors, change speed as needed. This makes cooling better and uses less energy.

- Picking energy-saving fan motors helps the environment. These motors cut carbon pollution and support green practices in cooling systems.

Understanding Refrigerator Cooling Fan Motors

What Are Cooling Fan Motors?

Cooling fan motors are essential components in refrigeration systems, responsible for driving the fans that circulate air within the appliance. These motors ensure consistent airflow, which prevents temperature fluctuations and maintains optimal cooling performance. The refrigeration industry offers various types of cooling fan motors, including shaded pole motors, permanent split capacitor (PSC) motors, and electronically commutated motors (ECMs). Shaded pole motors are known for their simplicity and reliability, while PSC motors provide improved energy efficiency. ECMs, although more complex and costly, deliver exceptional energy savings due to their advanced control electronics and precise speed regulation.

Industry standards further define the technical aspects of these motors. For instance:

- Operating Temperature of Thermal Protector: The activation temperature slightly exceeds the listed operating temperature.

- Impedance Protected: Designed to minimize current increases and temperature rises if the fan locks.

- Flammability Grade: Rated according to UL Standards (UL94) for fire retardancy.

These classifications ensure that cooling fan motors meet safety and performance benchmarks.

How They Work in Refrigerators

Cooling fan motors operate by powering the fan blades, which circulate air across the evaporator coils. This process facilitates heat exchange, ensuring the interior remains cool while excess heat is expelled. Advanced motors, such as ECMs, adjust their speed based on environmental conditions, optimizing energy use. This intelligent operation not only enhances cooling efficiency but also reduces strain on the compressor, extending the appliance's lifespan.

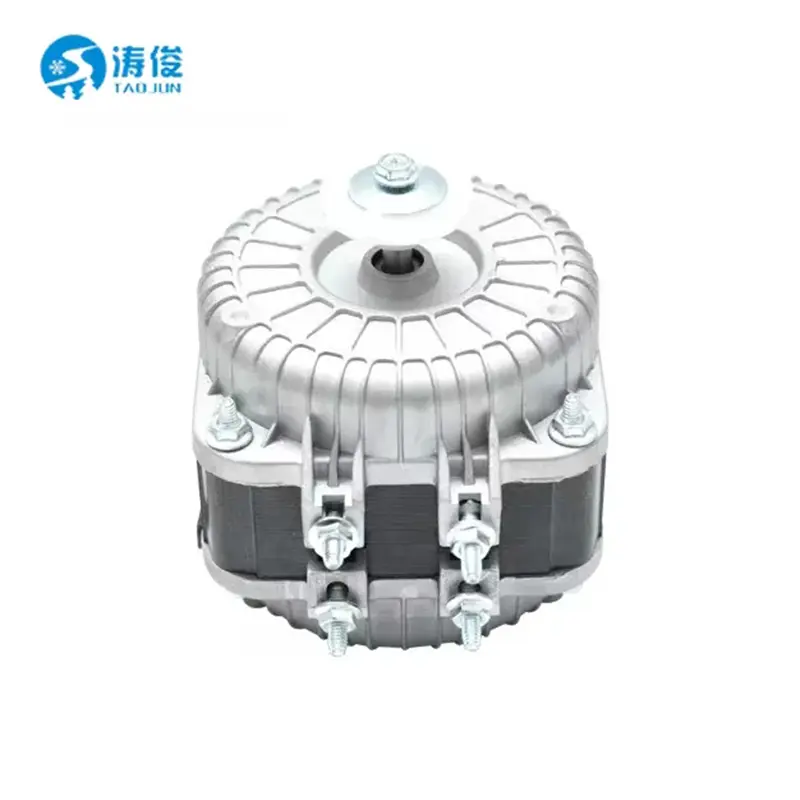

Refrigerator Cooling Fan Motor for B2B Procurement

For businesses, investing in high-quality cooling fan motors is a strategic decision. The global market for centrifugal cooling fans, valued at USD 3.5 billion in 2023, is projected to grow significantly due to rising demand for energy-efficient systems. Companies like Taojun HVAC offer reliable solutions tailored for commercial and industrial needs. Their Electric Cooling Fan Motor for Refrigerator and Freezer combines energy efficiency, durability, and quiet operation, making it an ideal choice for B2B procurement. By upgrading to advanced motors, businesses can reduce operational costs, enhance system reliability, and align with sustainability goals.

Energy Efficiency and Cooling Fan Motors

How Cooling Fan Motors Reduce Energy Consumption

Cooling fan motors play a critical role in reducing energy consumption in refrigeration systems. By optimizing airflow, these motors ensure efficient heat exchange, which minimizes the workload on compressors. Advanced motors, such as brushless DC motors, offer significant advantages over traditional AC motors. Their design enables quieter operation and longer lifespans, making them ideal for both residential and commercial applications.

Energy-efficient fans can achieve up to a 70% reduction in power usage compared to standard AC fans. For instance:

- Delta EC motor-based fans provide up to 70% power savings over traditional AC motor fans.

- Brushless DC motors reduce energy consumption while maintaining high performance.

These reductions translate into substantial cost savings for businesses and households alike. Companies investing in high-quality motors, such as Taojun HVAC's Electric Cooling Fan Motor, can benefit from lower operational expenses and improved system reliability.

The Role of Airflow in Maintaining Efficiency

Airflow is a fundamental factor in maintaining refrigeration efficiency. Proper airflow distribution ensures uniform temperature inside the refrigerator, reducing compressor cycles and enhancing energy efficiency. Computational Fluid Dynamics (CFD) models have been instrumental in analyzing airflow patterns and their impact on energy consumption.

| Evidence Description | Key Findings |

|---|---|

| Airflow distribution and heat transfer in cold storage rooms are analyzed using CFD models. | CFD models help in understanding airflow patterns and energy consumption, which are essential for optimizing refrigeration systems. |

| The cooling performance of different package designs was evaluated using CFD. | Redesigning vent holes improved airflow, cooling rates, and energy efficiency. |

| Environmental factors like solar radiation were incorporated into CFD models. | This helps in assessing their impact on energy usage in reefer containers. |

Optimized airflow management not only improves cooling rates but also stabilizes temperature distribution. Studies have shown that better airflow can achieve temperatures 1.5 °C to 5 °C lower than conventional designs, preserving food quality and reducing energy waste.

Benefits of DC Variable Frequency Motors

DC variable frequency motors represent a leap forward in refrigeration technology. These motors intelligently adjust their speed based on environmental conditions, ensuring precise temperature control and efficient operation. Inverter-driven refrigeration units equipped with DC motors consume approximately 30% less energy than traditional fixed-speed systems.

Laboratory tests have validated the performance improvements of DC motors. For example:

| Performance Metric | Value |

|---|---|

| Mass Flow | 1.65 g s−1 |

| Increase in Mass Flow | 11.33% |

| Input Frequency | 40.5 Hz |

| DC Excitation Voltage | 15 V |

These motors also enhance the coefficient of performance (COP), which measures the efficiency of refrigeration systems. By reducing energy consumption under variable load conditions, DC motors contribute to sustainability goals while lowering operational costs. Taojun HVAC's Electric Cooling Fan Motor exemplifies these benefits, offering businesses a reliable solution for energy-efficient refrigeration systems.

Benefits of Energy-Efficient Cooling Fan Motors

Lower Energy Bills

Energy-efficient cooling fan motors significantly reduce electricity costs by optimizing airflow and minimizing energy waste. These motors operate with advanced technologies, such as DC variable frequency systems, which intelligently adjust fan speed based on environmental conditions. This precise control ensures that refrigeration systems consume only the necessary amount of power, avoiding excessive energy usage.

For businesses, the financial impact is substantial. Upgrading to high-quality motors, such as Taojun HVAC's Electric Cooling Fan Motor, can lower operational expenses while maintaining reliable performance. In large-scale facilities, these savings accumulate over time, making energy-efficient motors a cost-effective investment. By incorporating these motors into refrigeration systems, companies can achieve long-term reductions in energy bills without compromising cooling efficiency.

Extended Appliance Lifespan

Energy-efficient cooling fan motors play a crucial role in extending the lifespan of refrigeration systems. By ensuring consistent airflow and reducing strain on compressors, these motors prevent overheating and mechanical wear. This optimized operation minimizes the risk of component failure, allowing appliances to function reliably for years.

Advanced motors, such as those offered by Taojun HVAC, are designed with durability in mind. Their high-quality construction and intelligent speed regulation reduce the frequency of maintenance and repairs. Businesses investing in these motors benefit from fewer disruptions and lower replacement costs. For B2B procurement, choosing reliable motors enhances system longevity, ensuring uninterrupted operations in commercial and industrial settings.

Environmental Advantages

Energy-efficient cooling fan motors contribute to environmental sustainability by reducing carbon emissions and energy consumption. Lifecycle Assessment (LCA) studies have quantified these benefits, demonstrating significant reductions in environmental impact. For example:

- The San Ace 9RA cooling fans achieve a 41% reduction in CO2 emissions over their lifecycle compared to traditional models.

- LCA calculations measure the environmental impact of products throughout their life cycles, including manufacturing, operation, and disposal.

By adopting motors like Taojun HVAC's Electric Cooling Fan Motor, businesses align with sustainability goals while lowering their carbon footprint. These motors not only conserve energy but also promote eco-friendly practices in refrigeration systems. For companies seeking environmentally responsible solutions, energy-efficient motors offer a practical and impactful choice.

Maintenance and Upgrades for Optimal Performance

Identifying Faulty Cooling Fan Motors

Detecting issues in cooling fan motors early is essential for maintaining refrigeration efficiency. Faulty motors often exhibit symptoms such as unusual noises, reduced airflow, or overheating. Advanced diagnostic techniques can help pinpoint these issues with precision.

This paper proposes vibration-based fan bearing fault detection through the wavelet transform and the Hilbert transform, emphasizing the importance of vibration measurement techniques in diagnosing cooling fan motor faults.

A vibration-based health monitoring approach for cooling fans is proposed using a wavelet filter for early detection of faults in fan bearings and for the assessment of fault severity.

The proposed method can effectively detect incipient defects and can better capture the degradation trend of fan bearings than traditional time-domain indices in vibration analysis.

These vibration-based diagnostic methods provide valuable insights into the health of cooling fan motors, enabling timely repairs and preventing costly breakdowns.

Maintenance Tips for Longevity

Proper maintenance ensures the long-term performance of cooling fan motors. Regular inspections and cleaning routines can significantly extend their lifespan. Key maintenance practices include:

- Inspect Fans Often: Check fan blades for dirt buildup, bent or broken parts, and signs of wear in the motor.

- Consistent Cleaning and Condenser Coil Maintenance: Clean condenser coils every three months to prevent overheating, especially in dusty or greasy environments.

- Gasket, Air Filter, and Seal Inspections: Regularly inspect these components to maintain system efficiency and reliability.

Adhering to these practices minimizes the risk of mechanical failure and ensures optimal airflow within refrigeration systems.

Upgrading to Taojun HVAC's Electric Cooling Fan Motor

Upgrading to Taojun HVAC's Electric Cooling Fan Motor offers a transformative solution for refrigeration systems. This motor combines energy efficiency, durability, and quiet operation, making it ideal for both residential and commercial applications. Its DC variable frequency technology intelligently adjusts fan speed, optimizing energy use and reducing operational costs.

Constructed with high-quality materials, the motor withstands harsh conditions, ensuring a long service life. Its compact design simplifies installation, while its low-noise operation enhances comfort in noise-sensitive environments. Businesses upgrading to this advanced motor benefit from improved system reliability, lower energy bills, and alignment with sustainability goals. Taojun HVAC's motor represents a smart investment for those seeking enhanced performance and efficiency.

Refrigerator cooling fan motors are indispensable for achieving energy-efficient refrigeration and reducing operational costs. Their role in optimizing airflow and minimizing compressor strain ensures consistent performance and prolonged appliance lifespan.

Tip: Regular maintenance and timely upgrades, such as Taojun HVAC's Electric Cooling Fan Motor, maximize efficiency and reliability.

Investing in energy-efficient motors not only lowers electricity bills but also supports environmental sustainability. Businesses and households alike benefit from these advanced solutions, making them a smart choice for long-term savings and eco-friendly practices. 🌱

FAQ

What is the primary function of a refrigerator cooling fan motor?

The cooling fan motor drives the fan blades to circulate air across the evaporator coils. This process ensures efficient heat exchange, maintains consistent cooling, and prevents temperature fluctuations inside the refrigerator.

How can businesses benefit from upgrading to energy-efficient cooling fan motors?

Energy-efficient motors reduce electricity costs, enhance system reliability, and align with sustainability goals. Businesses can achieve long-term savings and operational efficiency by investing in advanced motors like Taojun HVAC's Electric Cooling Fan Motor.

What are the signs of a faulty cooling fan motor?

Common signs include unusual noises, reduced airflow, and overheating. Early detection through vibration-based diagnostic methods can prevent costly repairs and ensure optimal refrigeration performance.

Why are DC variable frequency motors considered energy-efficient?

DC variable frequency motors intelligently adjust their speed based on environmental conditions. This precise control minimizes energy waste, reduces compressor strain, and enhances the overall efficiency of refrigeration systems.

How often should cooling fan motors undergo maintenance?

Regular maintenance, including cleaning condenser coils and inspecting fan blades, should occur every three months. Consistent upkeep ensures optimal performance, extends the motor's lifespan, and prevents mechanical failures.

Tip: Upgrading to Taojun HVAC's Electric Cooling Fan Motor simplifies maintenance and improves energy efficiency.