Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

Pre-Insulated Wire Tube Condensers for Supermarket Refrigeration Racks

Pre-Insulated Wire Tube Condensers for Supermarket Refrigeration Racks use advanced insulation technology to improve thermal efficiency and reduce unwanted heat transfer. These specialized condensers help supermarket refrigeration racks maintain consistent temperatures, which ensures optimal food preservation. Store operators notice immediate benefits such as lower energy consumption, quicker installation, and reduced maintenance requirements.

Key Takeaways

- Pre-insulated wire tube condensers improve refrigeration efficiency by reducing heat loss and stabilizing coil temperatures, which lowers energy use and extends equipment life.

- These condensers integrate well with supermarket parallel rack systems, supporting reliable temperature control and reducing operational costs.

- Installation is faster and simpler because the insulation is built-in, cutting labor time and minimizing errors during setup.

- Durable materials and insulation protect condensers from moisture and corrosion, increasing reliability and reducing maintenance needs.

- Following proper safety and maintenance practices, like regular inspections and careful refrigerant handling, ensures safe operation and long-lasting performance.

Pre-Insulated Wire Tube Condensers for Supermarket Refrigeration Racks: How They Work

Function in the Refrigeration Cycle

Pre-Insulated Wire Tube Condensers for Supermarket Refrigeration Racks play a vital role in the refrigeration cycle. These condensers facilitate the release of heat from the refrigerant vapor to the surrounding environment. As the refrigerant passes through the condenser coils, it changes from a high-pressure gas to a liquid, allowing the system to maintain a continuous cooling process. Pre-insulation technology enhances this stage by reducing the temperature of the air around the coils. Lower coil temperatures decrease thermal strain on the system, which leads to improved heat dissipation and more efficient condensation of the refrigerant. This process not only reduces energy consumption but also extends the lifespan of the equipment by minimizing wear and the risk of overheating. Stable operating temperatures help prevent system malfunctions and unplanned downtime, ensuring reliable performance for supermarket refrigeration racks.

Tip: Efficient heat transfer at the condenser stage is critical for maintaining the effectiveness of the entire refrigeration cycle. Pre-insulated designs optimize this process, supporting consistent indoor climate control and protecting temperature-sensitive products.

Integration with Parallel Rack Systems

Supermarkets often use parallel rack systems to manage multiple refrigeration loads efficiently. Pre-Insulated Wire Tube Condensers for Supermarket Refrigeration Racks integrate seamlessly with these systems, supporting advanced control strategies and energy optimization. Parallel rack systems use multiple compressors and condensers working together to balance load and maximize efficiency. Successful integration has been documented in several real-world applications:

| Case Study Name | Location/Type | System Description | Key Features |

|---|---|---|---|

| Morey’s Seafood | Supermarket (Retail) | Zero Zone parallel rack refrigeration system | Multiple compressors in parallel, customized design, energy efficient, reliable operation |

| Fresh Madison Market | Supermarket (Retail) | Zero Zone parallel rack refrigeration system | Advanced microprocessor control, load balancing, energy optimization, durability |

A notable example includes a Walgreens store in the United States, which achieved net zero energy status by integrating a CO2 trans-critical booster refrigeration system with parallel compressors and condensers. The system used geothermal boreholes to sub-cool the condenser, demonstrating significant energy efficiency and sustainability. These cases highlight how pre-insulated condensers contribute to precise temperature control, reliability, and reduced operational costs in supermarket environments.

Key Materials and Construction

The construction of Pre-Insulated Wire Tube Condensers for Supermarket Refrigeration Racks relies on advanced materials research. Engineers select materials that enhance thermal energy management, moisture control, and overall energy efficiency. Modern condensers often use borosilicate glass and glass-lined steel for their exceptional corrosion resistance and durability. The application of 3009 glass-lining provides unmatched chemical resistance, protecting components from harsh acids and solvents commonly found in refrigeration environments. These materials extend equipment life and reduce maintenance costs.

Recent advances in desiccants and membrane technologies further improve moisture management, supporting efficient latent and sensible cooling. Materials with high moisture absorption capacity and low regeneration energy requirements contribute to better condenser performance. The modular design of many condensers allows for optimization across various process conditions, including pressure, temperature, and heat transfer efficiency. These innovations ensure that supermarket refrigeration racks benefit from reliable, long-lasting, and high-performance condenser solutions.

Benefits of Pre-Insulated Wire Tube Condensers for Supermarket Refrigeration Racks

Energy Efficiency and Performance

Supermarkets demand refrigeration systems that operate efficiently around the clock. Pre-Insulated Wire Tube Condensers for Supermarket Refrigeration Racks deliver significant energy savings by minimizing heat loss and improving thermal transfer. The insulation layer reduces the impact of ambient temperature fluctuations. This feature allows the condenser to maintain optimal performance even during peak store hours or in challenging climates.

Operators notice a reduction in compressor cycling. The system does not need to work as hard to maintain set temperatures. Lower compressor activity translates to less energy consumption and reduced utility costs. Many supermarkets report measurable decreases in their monthly energy bills after upgrading to these condensers.

Note: Improved energy efficiency not only lowers operational costs but also supports sustainability goals. Supermarkets can reduce their carbon footprint while maintaining high standards for food safety and freshness.

Simplified Installation and Reduced Labor

Traditional condenser installations often require multiple steps, including separate insulation and complex mounting procedures. Pre-Insulated Wire Tube Condensers for Supermarket Refrigeration Racks streamline this process. The integrated insulation eliminates the need for additional wrapping or on-site modifications.

Installers benefit from a straightforward setup. Most units arrive ready for immediate placement, which reduces installation time and minimizes disruption to store operations. Fewer installation steps mean less risk of error and lower labor costs.

A typical installation process includes:

- Unpacking and inspecting the condenser unit.

- Positioning the unit within the rack system.

- Connecting refrigerant lines and electrical components.

- Verifying insulation integrity and system pressure.

This simplified approach allows technicians to complete projects faster and with greater confidence.

Enhanced Reliability and Longevity

Reliability remains a top priority for supermarket refrigeration. Pre-Insulated Wire Tube Condensers for Supermarket Refrigeration Racks use durable materials and advanced construction techniques. The insulation protects the condenser tubes from moisture, corrosion, and physical damage.

A well-insulated condenser experiences less thermal stress. This protection extends the lifespan of the equipment and reduces the frequency of maintenance calls. Supermarkets benefit from fewer unexpected breakdowns and lower long-term repair costs.

The following table highlights key reliability features:

| Feature | Benefit |

|---|---|

| Integrated insulation | Shields against moisture and corrosion |

| Robust tube materials | Withstands daily operational demands |

| Reduced thermal cycling | Minimizes wear on system components |

Tip: Regular maintenance checks further enhance the reliability of these condensers. Technicians should inspect insulation and connections to ensure peak performance year-round.

Installation of Pre-Insulated Wire Tube Condensers for Supermarket Refrigeration Racks

Preparation and Planning

Successful installation begins with careful preparation. Technicians review the refrigeration rack layout and verify compatibility with the condenser unit. They check all required tools and materials before starting. Site assessment helps identify the best location for airflow and accessibility. Proper planning ensures minimal disruption to store operations. Safety protocols, such as lockout/tagout procedures, protect workers during installation.

Tip: Always inspect the condenser and insulation for shipping damage before moving forward.

Step-by-Step Installation Process

A systematic approach leads to efficient installation. The following steps outline a typical process:

- Unpack the condenser and inspect for visible defects.

- Position the unit in the designated rack location.

- Secure the condenser using manufacturer-approved mounting hardware.

- Connect refrigerant lines, ensuring tight, leak-free joints.

- Attach electrical wiring according to the wiring diagram.

- Check insulation integrity along all tubing and joints.

- Pressurize the system and perform leak testing.

- Start the system and monitor initial operation.

Technicians document each step to maintain quality control and compliance with industry standards.

Overcoming Common Installation Challenges

Installers may encounter obstacles during setup. Tight spaces can make positioning difficult. In these cases, modular condenser designs offer flexibility. Technicians sometimes face alignment issues with refrigerant lines. Adjustable fittings and careful measurement help resolve these problems. Electrical connections require attention to detail to prevent faults. Clear labeling and double-checking connections reduce errors.

| Challenge | Solution |

|---|---|

| Limited space | Use modular or compact units |

| Misaligned piping | Employ adjustable fittings |

| Electrical complexity | Follow detailed wiring diagrams |

Note: Addressing challenges early prevents costly rework and ensures reliable system performance.

Safety Considerations for Pre-Insulated Wire Tube Condensers in Supermarket Refrigeration Racks

Electrical Safety Protocols

Electrical safety remains a top priority during installation and maintenance of pre-insulated wire tube condensers. Technicians must always disconnect power sources before beginning any work. They should use insulated tools and wear protective gloves to prevent accidental shocks. Clear labeling of electrical panels and wiring helps reduce confusion and mistakes. Regular inspection of electrical connections prevents corrosion and wear, which can lead to system failures or hazards.

Tip: Technicians should follow lockout/tagout procedures to ensure that equipment remains de-energized during service. This practice protects both personnel and equipment.

Refrigerant Handling and Environmental Safety

Proper refrigerant handling protects both people and the environment. Industry standards, such as ASHRAE 34 and ASHRAE 15, classify refrigerants by toxicity and flammability and set safety requirements for system design and operation. Real-world incidents, including ammonia leaks, have shown the importance of strict safety protocols. Effective refrigerant management reduces leaks, saves costs, and supports environmental safety goals. Non-compliance with regulations can result in financial penalties and reputational harm.

- ASHRAE 34 classifies refrigerants for safe handling.

- ASHRAE 15 sets safety standards for flammable refrigerants.

- Proper management reduces leaks and improves efficiency.

- Regulatory compliance supports corporate social responsibility.

Environmental research highlights the need for proper equipment, leak detection, and ventilation. Ongoing training ensures that technicians stay updated on new refrigerants and safety measures.

Maintenance and Inspection Guidelines

Routine maintenance and inspections extend the life of condensers and ensure safe operation. Regular coil cleaning prevents dirt buildup, which can reduce heat transfer efficiency. Lubricating moving parts and checking electrical connections help avoid mechanical and electrical failures. Monitoring refrigerant levels keeps the system running efficiently.

- Inspect coils for dirt, damage, or corrosion.

- Check refrigerant levels and look for leaks.

- Lubricate moving parts as recommended.

- Test electrical connections and controls.

- Maintain an operating log to track performance.

Note: These steps, performed at least twice a year, minimize downtime, improve energy efficiency, and help prevent unexpected breakdowns. Proactive care supports both safety and operational reliability.

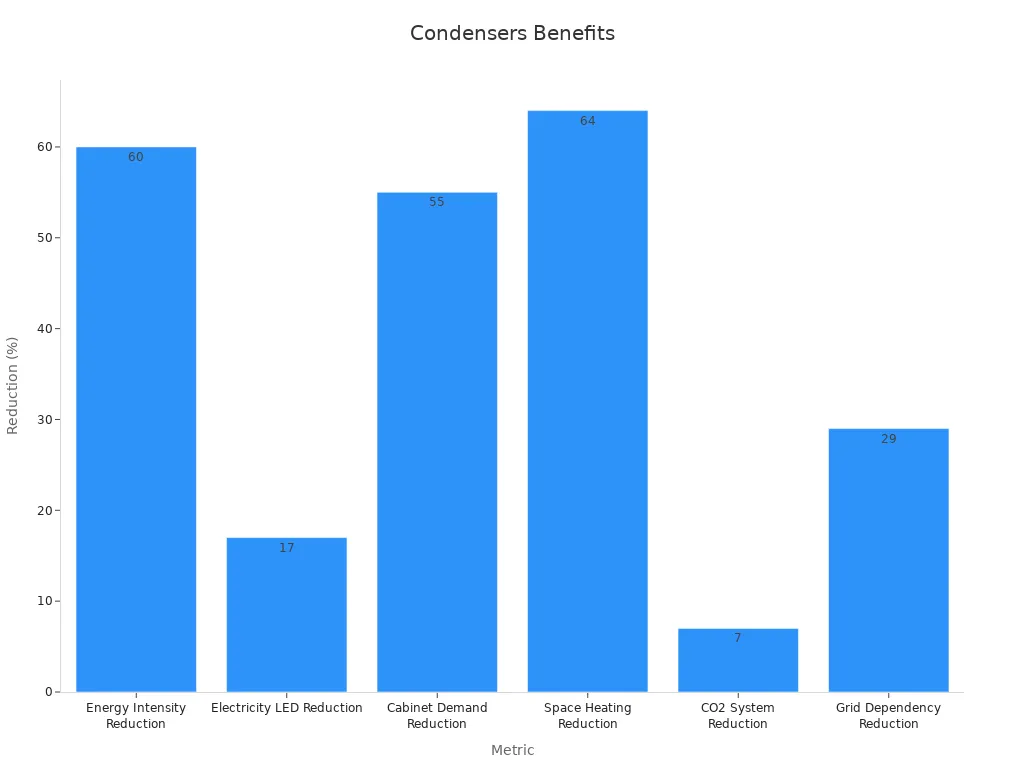

Supermarkets achieve remarkable energy and performance gains with advanced condenser technology. The table below highlights key metrics:

| Energy/Performance Metric | Benefit/Reduction |

|---|---|

| Energy use intensity reduction (advanced tech) | 60% reduction compared to basic reference |

| Annual energy use intensity | 140 kWh/m² |

| Electricity use reduction with LED lighting | 17% reduction |

| Medium-temperature cabinets refrigeration demand | 55% reduction |

| Space heating demand (with added doors in MT cabinets) | 64% reduction |

| Additional energy consumption reduction by heat recovery integration in CO2 system | 7% reduction |

| Grid dependency reduction by photovoltaic panels | 29% reduction |

| Thermal storage effect | Improved system efficiency via optimized subcooling |

Operators, managers, and technicians should consider these points:

- CO2 refrigeration systems offer strong energy and sustainability performance.

- Local energy sources and maintenance capabilities influence system selection.

- Financial incentives and photovoltaic integration can further improve outcomes.

- A multi-criteria approach ensures the best fit for each supermarket.

For those seeking reliable solutions, evaluating system performance in real-world conditions and consulting with experienced suppliers will support long-term success.

FAQ

What maintenance do pre-insulated wire tube condensers require?

Technicians should inspect insulation, clean coils, and check for leaks twice a year. Regular maintenance ensures optimal performance and extends equipment life. Operators benefit from fewer breakdowns and lower repair costs.

Can pre-insulated wire tube condensers fit existing supermarket rack systems?

Most pre-insulated wire tube condensers feature modular designs. These units integrate easily with standard supermarket rack systems. Technicians can retrofit them without major modifications.

How do pre-insulated condensers improve energy efficiency?

The insulation reduces heat loss and stabilizes coil temperatures. Compressors cycle less often, which lowers energy consumption. Supermarkets see reduced utility bills and improved sustainability.

Are these condensers compatible with different refrigerants?

Manufacturers design pre-insulated wire tube condensers for compatibility with common refrigerants, including CO₂ and HFCs. Always verify refrigerant compatibility with the supplier before installation.

Tip: Consult the product manual or supplier for specific refrigerant guidelines and best practices.