Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

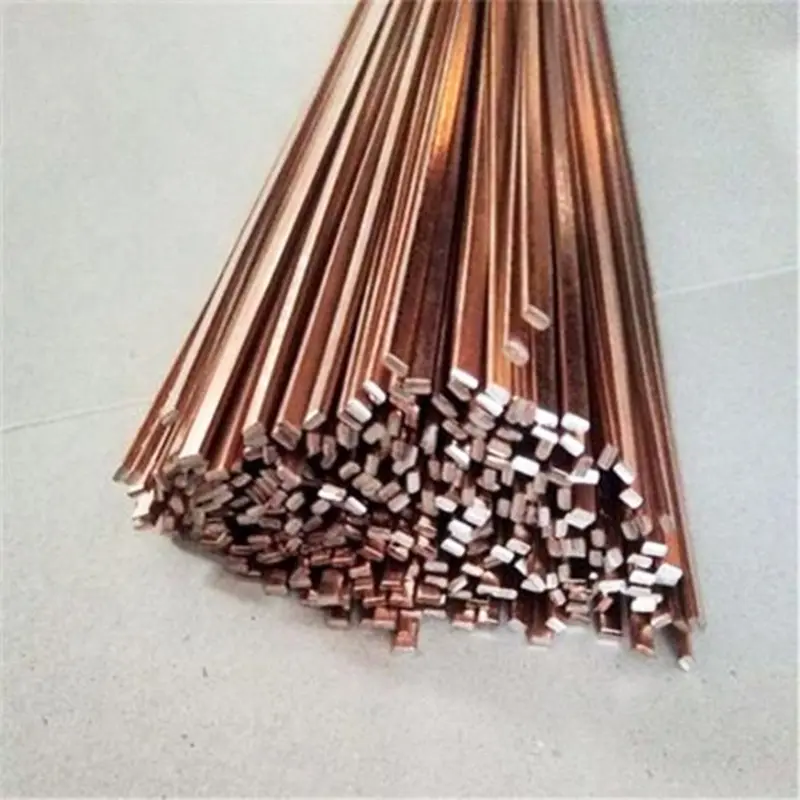

Is Copper Brazing Alloy the Key to HVAC Success?

Copper brazing alloy plays a pivotal role in the HVAC industry by ensuring the creation of strong and dependable joints. These joints significantly enhance system performance and extend operational life.

- The demand for energy-efficient HVAC systems continues to rise, driving the need for high-quality copper Brazing Materials. Their exceptional thermal conductivity and corrosion resistance are vital for maintaining system efficiency and durability.

- Copper brazing alloys are essential in air conditioners and refrigerators, where they provide superior mechanical strength and thermal transfer, directly impacting system longevity.

- The HVAC sector increasingly relies on copper brazing materials due to their ability to withstand high-pressure and high-temperature conditions, ensuring system reliability.

Studies reveal that inconsistencies in joint clearances can hinder the performance of copper-to-aluminum transition joints, which are critical in HVAC systems. Copper brazing alloy addresses this issue by forming robust, leak-proof connections.

Key Takeaways

- Copper brazing alloy makes strong, leak-free joints for HVAC systems.

- It helps heat move better, saving energy and lowering costs.

- The alloy resists rust, keeping parts safe from damage over time.

- It cuts repair costs by stopping leaks and reducing breakdowns.

- This material works with many methods, making setup faster and easier.

What is Copper Brazing Alloy?

Definition and Composition

Copper brazing alloy is a specialized filler metal designed to join copper and other metals through the brazing process. It consists primarily of copper, often combined with elements like phosphorus and silver to enhance its performance characteristics. The phosphorus content plays a critical role in determining the alloy's melting point and flow properties. Higher phosphorus levels improve fluidity, enabling better capillary action in joints, although excessive amounts can reduce ductility. Silver additions lower the melting temperature and improve ductility, making the alloy suitable for applications requiring precise joint formation.

For industrial applications, copper brazing alloys like CuBraz™ demonstrate exceptional wetting properties, ensuring effective bonding with various metals, including low-carbon and high-alloy steels. The uniform composition of these alloys minimizes material waste and reduces the likelihood of defects during brazing. This consistency makes copper brazing alloy a reliable choice for creating strong, durable joints in HVAC systems.

Unique Properties for HVAC Applications

Copper brazing alloy exhibits several unique properties that make it indispensable in HVAC systems. Its ability to flow seamlessly into small gaps ensures robust metallurgical bonds, even in intricate assemblies. The alloy's high thermal conductivity facilitates efficient heat transfer, which is crucial for maintaining optimal system performance. Additionally, its corrosion resistance protects joints from environmental degradation, extending the lifespan of HVAC components.

Scientific studies highlight the alloy's adaptability in challenging environments. For instance, research on Cu90PSn brazing filler metal reveals that minor additions of e-waste copper alloy can enhance fluidity and spreading properties, resulting in uniform joint structures. These findings underscore the alloy's versatility and reliability in high-pressure and high-temperature conditions common in HVAC systems.

Copper brazing alloy also eliminates the need for additional flux due to its phosphorus content, simplifying the brazing process and reducing operational costs. Its compatibility with various brazing methods, including gas flame and furnace brazing, further enhances its appeal for HVAC applications. These properties collectively make copper brazing alloy a cornerstone material for ensuring system efficiency and durability.

Key Benefits of Copper Brazing Alloy in HVAC Systems

Enhanced Durability

Copper brazing alloy provides unmatched durability, making it a preferred choice for HVAC systems. Its ability to withstand extreme temperature fluctuations ensures long-lasting performance. Heat cycle tests conducted on copper brazing alloys demonstrated their exceptional thermal shock resistance. These tests subjected samples to alternating temperatures between -50℃ and 175℃. Ultrasonic flaw inspections revealed no voids or material detachments, even after extensive cycling. This reliability ensures that HVAC systems maintain their structural integrity under demanding conditions, reducing the likelihood of joint failures and costly repairs.

The alloy's metallurgical bonding capabilities further enhance its durability. By forming robust joints, it minimizes the risk of leaks and mechanical failures. This makes it particularly suitable for high-pressure and high-temperature environments, such as those found in heat exchangers and compressors. The durability of copper brazing alloy directly contributes to the longevity and reliability of HVAC systems, ensuring consistent performance over time.

Superior Thermal Conductivity

Efficient heat transfer is critical for HVAC systems, and copper brazing alloy excels in this area. Its high thermal conductivity allows for rapid and uniform heat distribution, optimizing system efficiency. This property is especially beneficial in components like condensers and evaporators, where effective heat exchange is essential for maintaining desired temperatures.

A study on heat-pump condensers highlighted the advantages of using copper brazing alloy. Replacing microchannel tubes with smaller diameter copper tubes improved system efficiency and reduced costs. Similarly, in window air-conditioner condensers, the alloy enhanced efficiency while lowering refrigerant charge. These findings underscore the role of copper brazing alloy in boosting the overall performance of HVAC systems.

| Case Study Description | Findings |

|---|---|

| Heat-pump condensers replacing microchannel tubes | Improved system efficiency and reduced costs |

| Window air-conditioner condenser | Enhanced efficiency while lowering refrigerant charge |

| Refrigerator-Freezer Condenser | Reduced hydrocarbon refrigerant charge |

| Packaged terminal AC system condenser | Minimized raw material costs and airside pressure drop |

| Evaporator coil for heat pump water heater | Maximized capacity and minimized fan pumping power |

The superior thermal conductivity of copper brazing alloy not only enhances energy efficiency but also reduces operational costs. This makes it an indispensable material for modern HVAC systems striving to meet energy-saving goals.

Corrosion Resistance

Corrosion is a significant challenge in HVAC systems, as it can compromise joint integrity and lead to system failures. Copper brazing alloy offers excellent corrosion resistance, protecting joints from environmental factors such as moisture and chemical exposure. This resistance ensures that HVAC components remain functional and reliable, even in harsh operating conditions.

The phosphorus content in copper brazing alloy plays a crucial role in its corrosion resistance. By forming a natural barrier, it prevents oxidation and degradation of the joints. This property is particularly valuable in applications like heat exchangers and piping, where exposure to varying temperatures and humidity levels is common. The alloy's ability to resist corrosion reduces maintenance requirements and extends the lifespan of HVAC systems, providing long-term cost savings.

In addition to its inherent properties, copper brazing alloy eliminates the need for additional flux during the brazing process. This simplifies installation and minimizes the risk of introducing contaminants that could accelerate corrosion. Its compatibility with various brazing methods further enhances its versatility, making it a reliable choice for diverse HVAC applications.

Cost-Effectiveness

Cost-effectiveness remains a critical factor when selecting materials for HVAC systems. Copper brazing alloy offers significant financial advantages, making it an ideal choice for both manufacturers and end-users. Its unique properties reduce operational costs, extend system lifespan, and minimize maintenance expenses.

One of the primary ways copper brazing alloy enhances cost-efficiency is by preventing refrigerant leaks. In commercial refrigeration systems, such as those found in grocery stores, refrigerant loss can be a major expense. The average grocery store contains approximately 3,500 pounds of refrigerant, with nearly 25% lost annually due to leaks. These leaks often occur at vulnerable points like pipe joints, compressor coils, and evaporator tubing. Proper brazing techniques using copper brazing alloy create robust, leak-proof joints, significantly reducing refrigerant loss. This not only lowers repair costs but also decreases the need for frequent refrigerant refills, saving businesses thousands of dollars annually.

The alloy's durability further contributes to its cost-effectiveness. Its ability to withstand extreme temperatures and high pressures ensures long-lasting performance, reducing the frequency of joint failures. This reliability translates to fewer system breakdowns and lower repair costs over time. For HVAC manufacturers, this means fewer warranty claims and higher customer satisfaction, while end-users benefit from reduced downtime and maintenance expenses.

Copper brazing alloy also eliminates the need for additional brazing flux, thanks to its phosphorus content. This simplifies the brazing process and reduces material costs. Additionally, its compatibility with various brazing methods, such as gas flame and furnace brazing, allows for flexible and efficient installation. These factors collectively streamline production processes, enabling manufacturers to save on labor and equipment costs.

The energy efficiency of HVAC systems using copper brazing alloy further enhances its cost-effectiveness. By facilitating superior thermal conductivity, the alloy optimizes heat transfer, reducing energy consumption. This not only lowers utility bills but also helps businesses meet energy-saving goals, making it a sustainable and economical choice.

Applications of Copper Brazing Alloy in HVAC Systems

Heat Exchangers

Copper brazing alloy plays a vital role in manufacturing heat exchangers, which are essential for efficient thermal transfer in HVAC systems. Its high thermal conductivity ensures rapid and uniform heat distribution, optimizing system performance. The alloy’s corrosion resistance protects heat exchangers from environmental degradation, extending their operational life.

Modern manufacturing processes, such as CuproBraze technology, leverage copper brazing alloy to produce lightweight, durable heat exchangers. This method reduces energy requirements and minimizes waste, offering a 10% cost saving compared to conventional aluminum heat exchangers. Additionally, the alloy’s mechanical strength makes it suitable for high-temperature applications, ensuring reliability under demanding conditions.

| Property | Description |

|---|---|

| Thermal Conductivity | Excellent thermal conductivity, making them ideal for heat exchangers. |

| Corrosion Resistance | Strong resistance to oxidation and corrosion, enhancing durability in various environments. |

| Cost Efficiency | Offers a 10% cost saving over conventional aluminum heat exchangers. |

Compressors

Compressors rely on copper brazing alloy to maintain structural integrity under high-pressure conditions. The alloy’s ability to form robust metallurgical bonds ensures leak-proof connections, preventing refrigerant loss and reducing maintenance costs. Its durability allows compressors to withstand extreme temperature fluctuations, enhancing system reliability.

Copper-phosphorus alloys, known for their self-fluxing properties, simplify the brazing process in compressor manufacturing. These alloys exhibit excellent wetting and flow characteristics, ensuring uniform joint formation. Their resistance to oxidation further protects compressor components, making them ideal for long-term use in HVAC systems.

| Alloy Type | Key Features |

|---|---|

| Copper-Phosphorus Alloys | Self-fluxing properties, excellent wetting and flow characteristics for HVAC&R applications. |

| Copper-Silver Alloys | Superior thermal and electrical conductivity, excellent resistance to oxidation and corrosion. |

Piping and Tubing

Copper brazing alloy is indispensable for joining piping and tubing in HVAC systems. Its fluidity during the brazing process allows it to fill small gaps, creating strong, leak-proof joints. This ensures efficient refrigerant flow and minimizes the risk of system failures.

The alloy’s corrosion resistance protects piping and tubing from moisture and chemical exposure, reducing maintenance requirements. Its compatibility with various brazing methods, including gas flame and furnace brazing, enhances installation efficiency. As urbanization drives the demand for HVAC systems, copper brazing alloy remains a reliable choice for ensuring system durability and performance.

| Source | Key Insights |

|---|---|

| Brazing Alloy Materials Market | Highlights the growing demand for copper brazing filler metals in HVAC systems due to the expansion of the construction industry and advancements in alloy formulations. |

| Discover Innovative Braze Alloys | Discusses the applications of braze alloys in HVAC systems, emphasizing their strength and durability. |

| Braze Alloys Market | Notes the increasing use of braze alloys in HVAC systems driven by urbanization and industrialization. |

Copper Brazing Alloy vs. Alternatives

Copper Brazing Alloy vs. Aluminum

Copper brazing alloy outperforms aluminum in several critical aspects, making it a superior choice for HVAC applications. Its ability to create durable, leak-proof joints ensures long-term reliability, even under high-pressure and high-temperature conditions. Aluminum, while lightweight and cost-effective, often falls short in joint reliability and durability.

| Metric | Copper Sockets | Aluminum Sockets |

|---|---|---|

| Base Metal Erosion | Least | More |

| Consistent Tensile Strength Values | More | Less |

| Tensile Break Location | Aluminum Tube | Aluminum Tube |

| Complete Penetration Rate | 88% | 54% |

The table above highlights the superior performance of copper brazing alloy. Its higher penetration rate and consistent tensile strength values ensure robust connections, reducing the risk of joint failure. Aluminum sockets, on the other hand, exhibit higher base metal erosion and lower penetration rates, which compromise joint integrity over time.

Copper brazing alloy also demonstrates better adaptability to various brazing methods, such as gas flame and induction brazing. Studies show that inductive heating with copper brazing alloy is three times faster and consumes only 6% of the energy compared to gas torch heating. This efficiency, combined with its superior mechanical properties, makes copper brazing alloy the preferred material for HVAC systems.

Copper Brazing Alloy vs. Soldering Alloys

When compared to soldering alloys, copper brazing alloy offers significant advantages in strength, durability, and application suitability. Soldering alloys, which require lower temperatures, are often used for low-pressure applications. However, they lack the strength and reliability needed for high-pressure HVAC systems.

| Criteria | Brazing | Soldering |

|---|---|---|

| Temperature Requirements | Higher temperatures required | Lower temperatures used |

| Strength of Joints | Generally stronger joints | Weaker joints |

| Application Suitability | Suitable for high-pressure HVAC | Suitable for lower-pressure applications |

Copper brazing alloy forms stronger joints due to its ability to penetrate deeply into joint gaps, creating a robust metallurgical bond. This strength ensures that HVAC systems can withstand extreme conditions without compromising performance. Soldering alloys, while easier to work with, often result in weaker joints that are prone to leaks and failures under high pressure.

Additionally, copper brazing alloy eliminates the need for flux due to its phosphorus content, simplifying the brazing process and reducing costs. Its compatibility with various brazing methods further enhances its versatility, making it a reliable choice for modern HVAC systems.

Copper brazing alloy remains a cornerstone of HVAC success due to its ability to create durable, leak-proof joints that withstand temperature fluctuations and harsh conditions. Its superior thermal conductivity ensures efficient heat transfer, while its corrosion resistance protects components from environmental degradation. Brazing techniques using this alloy have become essential in HVAC systems, enabling reliable connections that enhance system longevity and reduce maintenance costs. As global construction activities and energy-efficient HVAC systems continue to grow, copper brazing alloy solidifies its role as a trusted solution for high-performance applications.

FAQ

What makes copper brazing alloy ideal for HVAC systems?

Copper brazing alloy offers superior thermal conductivity, corrosion resistance, and durability. Its ability to create leak-proof joints ensures reliable performance under high-pressure and high-temperature conditions. These properties make it indispensable for HVAC applications.

Can copper brazing alloy be used with different brazing methods?

Yes, copper brazing alloy is compatible with various methods, including gas flame, induction, and furnace brazing. Its fluidity and self-fluxing properties simplify the process, ensuring strong and uniform joints across diverse applications.

How does copper brazing alloy improve system efficiency?

Copper brazing alloy enhances heat transfer due to its high thermal conductivity. This reduces energy consumption and optimizes system performance, making HVAC systems more efficient and cost-effective.

Is copper brazing alloy suitable for high-pressure environments?

Absolutely. Copper brazing alloy forms robust metallurgical bonds that withstand extreme pressures and temperatures. This makes it ideal for components like compressors and piping in HVAC systems.

Does copper brazing alloy require additional flux during brazing?

No, the phosphorus content in copper brazing alloy acts as a natural flux. This eliminates the need for additional flux, simplifying the brazing process and reducing material costs.