Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

How Tom Liang Drives Innovation in OEM/ODM Refrigeration Solutions

As a leader in the refrigeration industry, I have always believed that innovation drives progress. Over nearly two decades, I’ve worked to redefine how high-quality OEM/ODM solutions to global refrigeration suppliers can transform their operations. These solutions form the backbone of efficient supply chains, helping manufacturers meet evolving market demands. My focus has been on creating systems that not only deliver exceptional performance but also set new benchmarks for reliability and sustainability. Through this work, I aim to advance the field and empower global suppliers to achieve their goals.

Key Takeaways

- Top-notch OEM/ODM solutions help products work better and last longer.

- Using energy-saving technology is key to helping the planet and saving money.

- Making products fit customer needs boosts happiness and loyalty to brands.

- Working with suppliers worldwide sparks new ideas and shared achievements.

- Keeping up with trends and using smart tech like AI and IoT helps businesses grow.

Understanding High-Quality OEM/ODM Solutions in Refrigeration

Defining OEM and ODM in the Refrigeration Industry

In the refrigeration industry, OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) solutions play distinct yet complementary roles. OEM solutions involve manufacturing products based on a client’s design specifications. In contrast, ODM solutions provide end-to-end services, from design to production, offering pre-designed products that clients can rebrand. Both approaches require precision and innovation to meet the unique demands of global refrigeration suppliers. I’ve found that blending these models allows us to deliver tailored solutions while maintaining scalability.

Why High-Quality OEM/ODM Solutions Matter to Global Suppliers

High-quality OEM/ODM solutions to global refrigeration suppliers are essential for maintaining competitive advantage. These solutions ensure operational efficiency, product reliability, and compliance with international standards. For example, we focus on metrics like sensor functionality and pressure monitoring to optimize system performance.

| Metric Type | Description |

|---|---|

| Sensor Functionality | Monitors parameters and states of the refrigeration system for efficient performance. |

| Pressure Monitoring | Ensures proper operation by measuring refrigerant pressure, indicating system status. |

Additionally, excellence in quality is non-negotiable. We aim for zero defects and reduced variability by leveraging advanced testing facilities, including component-level tests and system-level functional evaluations. This commitment not only enhances product performance but also builds trust with our partners.

Challenges in Delivering Superior OEM/ODM Refrigeration Products

Delivering superior OEM/ODM refrigeration products comes with its own set of challenges. Customization often complicates scaling production to meet high-volume demands. Reliability is another critical factor, especially for off-grid and edge-of-grid applications where consistent performance is vital.

| Challenge | Description |

|---|---|

| Customization | Varying deployment needs can impede achieving volume scale necessary for superior solutions. |

| Reliability | High reliability is a common requirement across new applications for off-grid and edge-of-grid solutions. |

| High-Volume Applications | The need for high-volume applications complicates the delivery of superior OEM/ODM refrigeration products. |

To overcome these hurdles, I prioritize robust project management, alternative component sourcing, and in-house rapid prototyping. These strategies allow us to adapt quickly to market demands while maintaining the high standards our clients expect.

Tom Liang’s Innovative Strategies for OEM/ODM Refrigeration Solutions

Leveraging Cutting-Edge Technologies and Processes

Innovation begins with technology. I have always prioritized the adoption of advanced technologies and streamlined processes to deliver high-quality OEM/ODM solutions to global refrigeration suppliers. By integrating state-of-the-art manufacturing techniques, such as automated assembly lines and precision engineering tools, we ensure consistent product quality and operational efficiency.

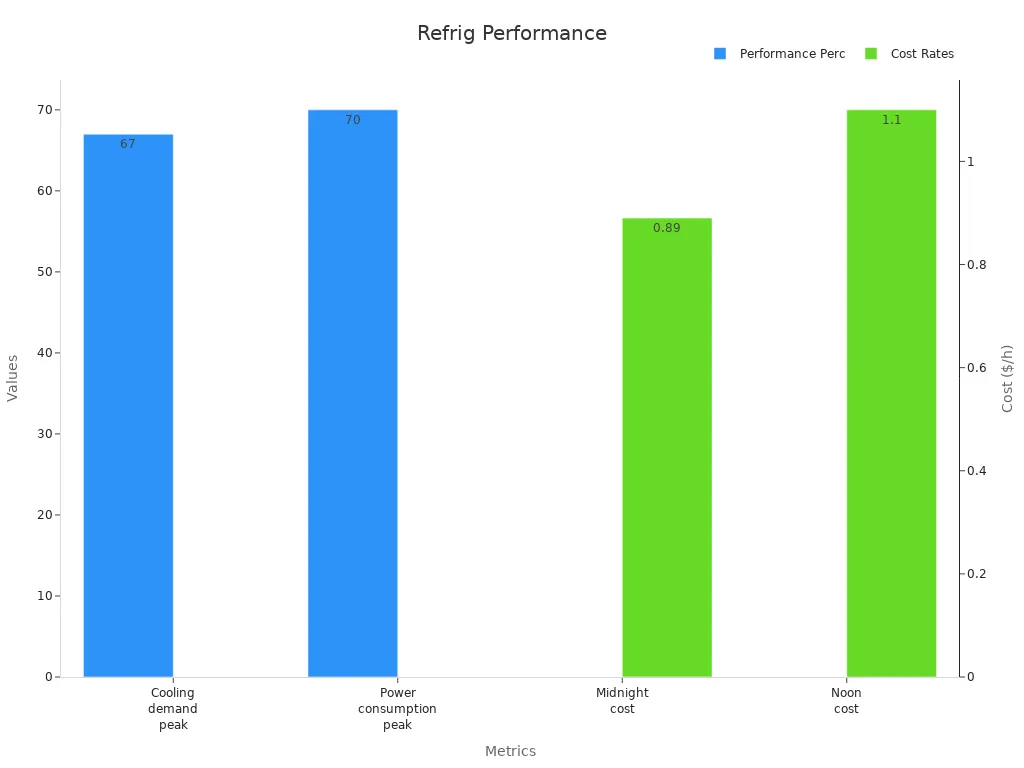

Our performance metrics speak for themselves. For instance, during peak hours, cooling demand reaches 67%, while power consumption remains at 70%. These figures highlight the efficiency of our systems in managing energy-intensive operations. Additionally, cost rates demonstrate our commitment to affordability, with a total cost of $0.89 per hour at midnight compared to $1.10 per hour at noon.

These results reflect the effectiveness of our innovative strategies in optimizing performance while minimizing costs. By continuously refining our processes, we stay ahead of industry trends and deliver solutions that exceed client expectations.

Prioritizing Sustainability and Energy Efficiency

Sustainability is no longer optional; it is a necessity. I have made it my mission to prioritize energy efficiency and environmentally friendly practices in all our refrigeration solutions. Research shows that air conditioning and refrigeration systems significantly contribute to greenhouse gas emissions, particularly in developing countries. This underscores the urgent need for sustainable innovations to combat climate change.

One example of our commitment to energy efficiency is the use of advanced condenser designs. A case study revealed that retrofitting a domestic refrigerator with an Elliptical Helical Coil Condenser improved its Coefficient of Performance (COP) from 2.45 to 2.59. Energy consumption dropped from 1755 Wh to 1191 Wh over 24 hours. These improvements not only reduce environmental impact but also lower operational costs for our clients.

By integrating such energy-efficient components into our products, we help global suppliers meet stringent environmental regulations while enhancing their market competitiveness. Sustainability remains at the core of our innovation strategy, driving us to develop solutions that benefit both businesses and the planet.

Building Collaborative Partnerships with Global Suppliers

Collaboration is the cornerstone of success in the refrigeration industry. Over the years, I have cultivated strong partnerships with global suppliers to create shared value and drive innovation. These collaborations enable us to align our goals with those of our partners, ensuring mutual growth and success.

For example, initiatives like the SPLC Procurement Climate Collaborative focus on reducing refrigerant emissions and improving climate strategies. This program helps organizations track and reduce Scope 1 emissions, aligning with corporate climate goals. Similarly, the Supplier Renewables initiative supports the adoption of renewable energy solutions, promoting clean energy practices across sectors.

| Initiative | Description | Benefits |

|---|---|---|

| SPLC Procurement Climate Collaborative | Reduces refrigerant emissions and improves climate strategies. | Tracks and reduces Scope 1 emissions, aligning with corporate climate goals. |

| Supplier Renewables with CEAP Initiative | Supports suppliers in adopting renewable energy solutions. | Facilitates shared value creation and promotes clean energy initiatives. |

| PCC Launch Meeting Results | Develops strategies among 40+ organizations. | Provides a roadmap for impactful market demands for sustainable solutions. |

These partnerships not only enhance our ability to deliver high-quality OEM/ODM solutions to global refrigeration suppliers but also strengthen our position as a leader in the industry. By working together, we can achieve greater innovation, sustainability, and market impact.

Customization and Flexibility in Product Development

Customization and flexibility are the cornerstones of successful OEM/ODM refrigeration solutions. Over the years, I’ve learned that no two clients have identical needs. Each supplier operates within unique market conditions, requiring tailored products that align with their brand identity and customer expectations. This understanding drives my approach to product development, ensuring every solution meets specific requirements while maintaining scalability.

Flexibility in product design allows us to adapt quickly to changing market demands. For instance, ODM solutions provide the ability to modify designs and features, enabling suppliers to better align products with their target audience. This adaptability not only enhances brand differentiation but also ensures relevance in competitive markets.

- Key Benefits of Customization and Flexibility:

- ODM solutions enable modifications that reflect brand identity and customer preferences.

- Tailored products meet specific market demands, improving customer satisfaction.

- Collaborative OEM/ODM partnerships enhance cost efficiency through streamlined processes.

Tip: Customization isn’t just about aesthetics; it’s about functionality. A well-designed refrigeration system should optimize performance while addressing the unique challenges of its intended application.

I’ve also found that flexibility in production processes plays a critical role in achieving cost efficiency. By fostering close collaboration with suppliers, we streamline operations and reduce unnecessary expenses. This approach ensures that even highly customized products remain affordable for our clients. For example, when working with global partners, we assess supplier capabilities to identify opportunities for improvement. This assessment often leads to enhanced production workflows and reduced lead times.

The ability to tailor products extends beyond design. It includes adapting to regional regulations, environmental standards, and specific use cases. For instance, some markets demand refrigeration systems with advanced energy-saving features, while others prioritize durability in extreme climates. By offering flexible solutions, we empower suppliers to meet these diverse needs without compromising quality.

Customization and flexibility are not just strategies; they are commitments to excellence. They allow us to deliver refrigeration solutions that resonate with customers, strengthen supplier relationships, and drive innovation across the industry. As I continue to refine these practices, my goal remains the same: to create products that exceed expectations and set new benchmarks for performance and reliability.

The Industry Impact of Tom Liang’s Work

Enhancing Operational Efficiency for Global Suppliers

Operational efficiency is the foundation of success for global refrigeration suppliers. I have always prioritized creating solutions that streamline processes, reduce costs, and enhance productivity. By leveraging advanced manufacturing techniques and automation, we have significantly improved the efficiency of our production lines. For instance, automated assembly lines not only minimize human error but also ensure consistent quality across high-volume outputs.

One of the key strategies I employ is optimizing supply chain management. Collaborating closely with suppliers allows us to identify bottlenecks and implement solutions that enhance workflow. For example, by integrating real-time tracking systems, we ensure timely delivery of components, reducing downtime and maintaining production schedules. This approach has enabled our partners to meet tight deadlines without compromising on quality.

Efficiency also extends to the performance of our refrigeration products. High-quality OEM/ODM solutions to global refrigeration suppliers are designed with precision to maximize energy savings and minimize maintenance requirements. This dual focus on operational and product efficiency empowers our partners to achieve their business goals while maintaining a competitive edge in the market.

Promoting Sustainability in Refrigeration Practices

Sustainability is at the heart of my innovation strategy. I believe that the refrigeration industry has a responsibility to adopt greener practices and reduce its environmental footprint. To this end, I have championed the integration of eco-friendly technologies into our product designs.

| Technology | Benefits |

|---|---|

| CO2 Refrigerant | Low Global Warming Potential (GWP of 1), non-toxic, non-flammable, lower leakage rates, cost-effective over time. |

| Thermoelectric Cooling | Energy-efficient, silent operation, no moving parts, environmentally friendly, uses only water. |

| Magnetic Refrigeration | Innovative cooling method with potential for high efficiency and reduced environmental impact. |

| Refrigerant Tracking Tech | Helps monitor and reduce refrigerant leaks, enhancing overall system sustainability. |

These technologies not only reduce greenhouse gas emissions but also offer long-term cost savings for our clients. For example, CO2 refrigerants provide a sustainable alternative to traditional options, with lower leakage rates and a minimal environmental impact. Similarly, magnetic refrigeration represents a groundbreaking innovation with the potential to revolutionize the industry.

I also advocate for the adoption of refrigerant tracking technologies. These systems help monitor and minimize leaks, ensuring compliance with environmental regulations. By promoting these practices, I aim to create a more sustainable future for the refrigeration industry while helping our partners align with global climate goals.

Elevating Customer Satisfaction Through Tailored Solutions

Customer satisfaction is the ultimate measure of success. I have always emphasized the importance of understanding client needs and delivering solutions that exceed their expectations. Tailored refrigeration products play a crucial role in achieving this goal. Each solution is designed to address specific challenges, whether it’s optimizing energy efficiency, enhancing durability, or meeting regional regulatory requirements.

Direct feedback from customers provides invaluable insights into their preferences and pain points. This feedback guides our product development process, ensuring that every solution aligns with market demands. Additionally, key performance indicators (KPIs) help us evaluate the success of our offerings and identify areas for improvement. By focusing on these metrics, we continuously refine our strategies to deliver exceptional value.

- Key Benefits of Tailored Solutions:

- Enhanced alignment with customer needs and market trends.

- Improved brand loyalty through personalized offerings.

- Increased operational efficiency by addressing specific use cases.

For example, when working with a client in a region with extreme climates, we developed a refrigeration system with advanced insulation and energy-saving features. This solution not only met the client’s requirements but also improved their customer satisfaction ratings. Such tailored approaches strengthen our relationships with partners and reinforce our reputation as a leader in the industry.

By prioritizing customization and actively seeking client feedback, I ensure that our solutions remain relevant and impactful. This commitment to excellence drives customer satisfaction and positions us as a trusted partner in the global refrigeration market.

Expanding Brand Visibility and Market Reach for Partners

Expanding brand visibility and market reach for our partners has always been a priority in my work. I believe that a strong brand presence not only enhances credibility but also opens doors to new opportunities in competitive markets. Over the years, I’ve developed strategies that help our partners amplify their reach while solidifying their reputation as leaders in the refrigeration industry.

One of the most effective ways to achieve this is through active participation in professional circles. By engaging with industry associations, trade shows, and technical forums, we position our partners as trusted vendors. This recognition significantly influences purchasing decisions, as customers tend to prefer brands with established credibility. I’ve seen firsthand how this approach builds trust and fosters long-term relationships.

Another key strategy involves leveraging digital marketing techniques. By emphasizing technical knowledge and providing robust support through online platforms, we help our partners connect with diverse industries. This not only fortifies their brand visibility but also ensures ongoing business relationships. For instance, targeted campaigns showcasing innovative product features often resonate with specific customer segments, driving both awareness and engagement.

| Evidence Description | Impact on Brand Visibility and Market Reach |

|---|---|

| Active participation in professional circles amplifies brand credibility. | Being recognized as a preferred vendor influences purchasing decisions significantly. |

| Tangible ROI narratives reassure decision-makers. | Effective case studies help sales teams close deals faster, enhancing market reach. |

| Local outreach fosters brand awareness across customer segments. | Community engagement leads to increased recall and preference when customers need new equipment. |

| Leveraging digital marketing techniques emphasizes technical knowledge and support. | This approach fortifies brand visibility and builds trust across diverse industries, securing ongoing business relationships. |

Local outreach also plays a pivotal role in expanding market reach. By fostering community engagement, we create meaningful connections with end-users. This approach increases brand recall and ensures our partners remain top-of-mind when customers require new equipment. For example, collaborating with local distributors to host product demonstrations has proven highly effective in building awareness and trust.

Tangible ROI narratives further enhance our partners’ market presence. Case studies showcasing measurable results reassure decision-makers and provide compelling evidence of product value. These narratives empower sales teams to close deals faster, ultimately broadening market reach. I’ve worked closely with partners to craft these stories, ensuring they highlight both technical excellence and real-world impact.

In today’s competitive landscape, a multi-faceted approach is essential for success. By combining professional engagement, digital marketing, local outreach, and ROI-driven storytelling, we help our partners achieve unparalleled visibility and growth. My goal remains to empower them with the tools and strategies needed to thrive in an ever-evolving market.

Leadership Lessons from Tom Liang

The Role of Cross-Departmental Collaboration in Innovation

Innovation thrives when diverse minds come together. I’ve always believed that cross-departmental collaboration is the key to unlocking groundbreaking ideas. At Taojun Refrigeration, I encourage teams from engineering, marketing, and customer service to work closely. This approach fosters a culture where different perspectives converge, leading to solutions that address complex challenges.

By breaking down silos, we’ve developed refrigeration solutions that are not only efficient but also tailored to meet diverse market needs. This collaborative approach has strengthened our ability to adapt and innovate, keeping us ahead in a competitive industry.

Adapting to Market Trends and Customer Needs

The refrigeration industry evolves rapidly, and staying ahead requires adaptability. I’ve made it a priority to align our solutions with emerging market trends and customer demands. This strategy ensures that our products remain relevant and impactful.

- Growing demand for adaptive and remote-control technologies has reshaped customer expectations. These innovations enhance operational flexibility and efficiency.

- The rise of e-commerce and online grocery sectors has increased the need for advanced cold storage and logistics capabilities.

- Rising energy costs and stricter environmental regulations push businesses to adopt eco-friendly and energy-efficient refrigeration systems.

By closely monitoring these trends, I’ve guided my team to develop solutions that address these challenges. For instance, we’ve integrated remote monitoring features into our products, enabling clients to optimize performance in real-time. This adaptability not only meets customer needs but also positions us as a leader in the industry.

Fostering a Culture of Continuous Improvement

Continuous improvement is the cornerstone of success. I’ve cultivated a culture where every team member strives to enhance processes, products, and services. This mindset ensures that we remain agile and responsive to industry demands.

Organizations like McDonald’s and Walmart demonstrate the power of continuous improvement. McDonald’s applied Lean principles to optimize inventory systems, improving service quality and reducing costs. Walmart utilized Six Sigma to streamline supply chain operations, achieving better visibility and lower logistics expenses. Inspired by these examples, I’ve implemented similar methodologies at Taojun Refrigeration.

| Organization | Methodology | Key Outcomes |

|---|---|---|

| McDonald's | Lean Principles | Enhanced service quality and reduced costs through optimized inventory systems. |

| Walmart | Six Sigma | Improved supply chain visibility and reduced logistics costs. |

| Delta Air Lines | Agile | Rapid updates to customer-facing systems improved customer experience. |

| Mayo Clinic | Six Sigma | Reduced patient wait times and improved clinical outcomes. |

| Hochschild Mining | Crowdsourcing | Generated a $40M drilling optimization strategy through employee insights. |

At Taojun, we’ve adopted Lean principles to refine our production processes, ensuring efficiency and quality. By fostering this culture, we empower our team to innovate continuously, delivering solutions that exceed client expectations and set industry benchmarks.

The Future of High-Quality OEM/ODM Refrigeration Solutions

Emerging Technologies Shaping Refrigeration Solutions

The refrigeration industry is undergoing a transformation driven by emerging technologies. I’ve observed that advancements like energy-efficient refrigeration units and eco-friendly refrigerants are reshaping the landscape. These innovations not only reduce electricity usage but also align with global sustainability goals. For instance, smart refrigeration technology now leverages IoT for real-time monitoring, enhancing food safety and minimizing spoilage risks. Variable speed compressors, which adjust operation based on cooling needs, further improve efficiency and extend equipment lifespan.

| Key Market Drivers | Description |

|---|---|

| Booming Food Retail and HoReCa Sectors | Urbanization and lifestyle shifts are increasing demand for processed and frozen food products. |

| Rising Demand in Pharmaceuticals | Refrigeration is essential for storing vaccines and temperature-sensitive medicines. |

| Sustainability & Energy Efficiency | Energy-efficient refrigerators with low-GWP refrigerants are gaining popularity. |

These trends highlight the growing importance of high-quality OEM/ODM solutions to global refrigeration suppliers. By staying ahead of these developments, I ensure our products meet evolving market demands.

The Integration of AI and IoT in Product Development

AI and IoT are revolutionizing refrigeration product development. I’ve seen how these technologies optimize food quality, reduce waste, and enhance energy efficiency. Many of our customers already have data-rich infrastructures, including sensors and controls, which we utilize to deliver actionable insights without extensive retrofitting. Predictive maintenance, enabled by AI, helps identify potential issues before they escalate, reducing downtime and repair costs.

However, challenges remain. Traditional technology companies often lack an understanding of refrigeration-specific needs. Accessing data from controllers for cloud-based models can also be difficult. Despite these hurdles, I believe the integration of AI and IoT will continue to drive innovation, offering smarter, more efficient solutions for our clients.

Tom Liang’s Vision for the Next Decade of Innovation

Looking ahead, my vision for the next decade focuses on sustainability, customization, and technological integration. I aim to develop refrigeration systems that not only meet but exceed environmental standards. By incorporating advanced features like magnetic refrigeration and eco-friendly refrigerants, we can significantly reduce the industry’s carbon footprint.

Customization will remain a cornerstone of our strategy. Each client has unique needs, and I plan to expand our capabilities to deliver even more tailored solutions. Additionally, I see AI and IoT playing a pivotal role in creating intelligent systems that adapt to real-time conditions. My goal is to lead the industry in providing high-quality OEM/ODM solutions to global refrigeration suppliers, setting new benchmarks for performance and reliability.

Over the years, I have dedicated myself to advancing high-quality OEM/ODM solutions to global refrigeration suppliers. My work has focused on creating innovative, sustainable, and tailored products that empower suppliers to thrive in competitive markets. These efforts have not only enhanced operational efficiency but also set new standards for reliability and environmental responsibility across the industry.

Looking ahead, I see immense potential for the refrigeration sector to embrace emerging technologies and redefine its role in a sustainable future. My vision is to continue driving innovation that aligns with global needs while ensuring our partners achieve unparalleled success. Together, we can shape the next chapter of refrigeration excellence.

FAQ

What sets Taojun Refrigeration apart in the OEM/ODM refrigeration industry?

Our commitment to innovation, sustainability, and customization distinguishes us. I prioritize advanced technologies, eco-friendly practices, and tailored solutions to meet diverse client needs. This approach ensures high-quality products that align with global standards and exceed customer expectations.

How does Taojun Refrigeration ensure product quality?

We implement rigorous quality control measures at every stage of production. Advanced testing facilities, including component-level and system-level evaluations, guarantee reliability. By adhering to international certifications like ISO9001 and UL, we maintain consistent excellence.

Why is sustainability a priority in refrigeration solutions?

Refrigeration systems significantly impact the environment. I focus on energy-efficient designs and eco-friendly refrigerants to reduce greenhouse gas emissions. This not only supports global climate goals but also lowers operational costs for our clients.

How does Taojun Refrigeration address customization needs?

I believe every client has unique requirements. We offer flexible OEM/ODM solutions, allowing modifications in design, features, and functionality. This adaptability ensures our products align with specific market demands and customer preferences.

What role does collaboration play in your innovation strategy?

Collaboration drives innovation. I foster partnerships with global suppliers and encourage cross-departmental teamwork within Taojun. This approach combines diverse expertise, enabling us to develop groundbreaking refrigeration solutions that meet evolving industry needs.