Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

How to Maintain HVAC Systems with High Performance Vacuum Pumps

High-performance vacuum pumps are essential tools for maintaining HVAC systems. The High Performance Vacuum Pump Single-Stage 5 Pa Rotary Vane Economy Vacuum Pump by Taojun effectively removes air, moisture, and contaminants from these systems. This process ensures efficient heat exchange and prevents potential damage caused by frozen moisture or accumulated gases.

- Removing contaminants and moisture extends the lifespan of HVAC systems.

- The demand for energy-efficient HVAC systems highlights the importance of using advanced vacuum pumps for optimal performance.

Proper maintenance with high-quality vacuum pumps reduces energy consumption and minimizes repair costs, making them indispensable for HVAC care.

Key Takeaways

- Strong vacuum pumps help remove air and moisture from HVAC systems. This keeps them working well and avoids damage.

- Taking care of vacuum pumps, like changing oil and checking them, makes them work better and last longer.

- Picking the right vacuum pump for the system size and needs is key for saving energy and working well.

- Watching the vacuum process is important to remove all dirt. This keeps the system reliable and working smoothly.

- Checking after maintenance helps find problems early. This keeps HVAC systems safe and working properly.

Why High-Performance Vacuum Pumps Are Essential for HVAC Maintenance

The Role of Vacuum Pumps in HVAC Systems

Vacuum pumps play a critical role in maintaining HVAC systems by ensuring proper air pressure and circulation. These pumps remove air, moisture, and non-condensable gases that can hinder system performance. Their operation involves creating a pressure differential, which allows moisture to vaporize and escape more easily. This process prevents corrosion and blockages caused by frozen moisture, safeguarding the system's integrity.

- Vacuum pumps maintain optimal air pressure and quality within HVAC systems.

- They clear blockages in ducts and vents, restoring airflow and improving efficiency.

- By enhancing air circulation, they contribute to energy savings, especially in large commercial buildings.

In air conditioning and refrigeration systems, vacuum pumps eliminate contaminants that can reduce heat exchange efficiency. Their ability to optimize pressure levels ensures smooth operation, reducing the risk of costly repairs or system failures.

Benefits of Using High-Performance Vacuum Pumps

High-performance vacuum pumps offer several advantages that make them indispensable for HVAC maintenance. Research shows that these pumps are essential for achieving energy efficiency and reducing operational costs. Their advanced design accelerates processes like vacuum forming and drying, while also minimizing energy consumption.

- Improved Efficiency: High-performance pumps optimize HVAC operations, ensuring consistent airflow and temperature control.

- Reduced Waste: By removing contaminants, they prevent system downtime and extend equipment lifespan.

- Cost Savings: Enhanced efficiency leads to lower energy bills and fewer maintenance expenses.

Industries such as food and beverage, pharmaceuticals, and manufacturing benefit from the clean environments maintained by these pumps. Their ability to prevent defects and contamination highlights their value across various applications.

How the High Performance Vacuum Pump Single-Stage 5 Pa Rotary Vane Economy Vacuum Pump Enhances System Longevity

The High Performance Vacuum Pump Single-Stage 5 Pa Rotary Vane Economy Vacuum Pump by Taojun is specifically designed to enhance HVAC system longevity. Its robust aluminum alloy casing ensures durability, even under demanding conditions. The pump's precise cylinder construction achieves a higher ultimate vacuum, effectively removing air and moisture from the system.

One standout feature is its anti-suckback design, which prevents pump oil from flowing back into the vacuum chamber. This ensures clean and efficient operation, reducing the risk of contamination. The oversized sight glass allows users to monitor oil levels easily, ensuring the pump operates at peak performance.

Available in multiple models, this vacuum pump caters to various flow rate requirements. For example, the VP115 model offers a flow rate of 1.5CFM, making it ideal for smaller applications. Larger models, such as the VP2100, provide up to 10CFM, meeting the needs of industrial-scale HVAC systems. By using this high-performance vacuum pump, users can prevent system failures, improve efficiency, and extend the operational lifespan of their HVAC equipment.

Step-by-Step Guide to Maintaining HVAC Systems with Vacuum Pumps

Preparing the HVAC System for Maintenance

Proper preparation ensures the efficiency and safety of HVAC maintenance. Before starting, technicians should follow essential preparatory steps to avoid complications during the vacuum process.

- Disconnect the power supply to eliminate electrical hazards.

- Allow the vacuum pump to cool completely to prevent burns from hot surfaces.

- Wear gloves and safety glasses to protect against oil splashes and contaminants.

- Ensure the workspace is well-ventilated to avoid inhaling harmful vapors.

- Use proper lifting techniques when handling heavy equipment to prevent injuries.

Maintaining cleanliness is equally important. Tubing should remain sealed with original plugs or caps until assembly. Before cutting, clean the tubing to remove contaminants, and ream carefully to prevent shavings from entering the lines. Protect open pipework from rainwater or condensation, and replace filter/driers as needed. Purging the system with nitrogen before and after brazing ensures no debris or moisture remains.

Additionally, technicians should use large-diameter vacuum hoses and keep them as short as possible to maximize efficiency. Removing or fully depressing cores and connecting directly from the pump to CRTs (core removal tools) eliminates unnecessary restrictions. After achieving the desired vacuum level, isolate and test the system to confirm there are no leaks or residual moisture.

Tip: Always dispose of used oil and filters according to local environmental regulations to maintain compliance and sustainability.

Setting Up the High Performance Vacuum Pump Single-Stage 5 Pa Rotary Vane Economy Vacuum Pump

Setting up the High Performance Vacuum Pump Single-Stage 5 Pa Rotary Vane Economy Vacuum Pump requires attention to detail to ensure optimal performance. Begin by inspecting the pump for any visible wear or damage. Check the oil level through the oversized sight glass and refill with clean oil if necessary. This step prevents contamination and ensures smooth operation.

Position the pump on a stable, level surface to avoid vibrations during use. Connect the pump to the HVAC system using appropriate fittings and hoses. Ensure all connections are tight and secure to prevent leaks. For best results, avoid using a manifold and connect the pump directly to the system.

Once connected, power on the pump and allow it to run for a few minutes to stabilize. Monitor the anti-suckback valve to ensure it functions correctly, preventing oil from flowing back into the vacuum chamber. This feature is crucial for maintaining a clean and efficient vacuum process.

Note: Regular calibration of the vacuum pump ensures it operates within specified parameters, providing accurate vacuum levels and preventing errors in pressure measurements.

Monitoring the Vacuum Process for Optimal Results

Monitoring the vacuum process is essential for achieving the desired vacuum level and ensuring the system is free of contaminants. Begin by observing the vacuum gauge to track pressure levels. A steady drop in pressure indicates the removal of air and moisture. If the pressure stabilizes prematurely, check for leaks or blockages in the system.

Vacuum drying is a critical step in this process. It removes residual moisture from the HVAC system, preventing issues like freezing and corrosion. Technicians should also conduct leak tests using tracer gas dilution methods, such as helium or hydrogen, to ensure thorough coverage. Adjusting the probe distance and angle during the sniffing process improves leak detection accuracy.

Once the desired vacuum level is achieved, isolate the system and perform a final test to confirm there are no leaks. This step validates the effectiveness of the vacuum process and ensures the system is ready for refrigerant filling.

Pro Tip: Regular maintenance of the vacuum pump, including oil changes and wear inspections, minimizes downtime and ensures peak performance during HVAC maintenance.

Post-Maintenance Checks and System Reassembly

Post-maintenance checks and system reassembly are critical steps in ensuring HVAC systems operate efficiently and safely after servicing. These steps verify that all components function correctly and that the system is ready for optimal performance.

Importance of Post-Maintenance Inspections

Post-maintenance inspections help identify potential issues early, ensuring the HVAC system performs at its best. Technicians can detect and address minor problems before they escalate into costly repairs. Regular inspections also enhance indoor air quality and extend the system's lifespan.

Note: Inspections are essential for safety. They prevent hazards like electrical fires or carbon monoxide leaks, protecting both property and occupants.

Key benefits of post-maintenance inspections include:

- Uncovering failing components for proactive replacement.

- Logging performance metrics to prevent unexpected failures.

- Building trust by addressing safety risks transparently.

These inspections ensure compliance with warranty requirements and provide peace of mind for homeowners and businesses alike.

Steps for Post-Maintenance Checks

-

Inspect System Components

Technicians should examine all components, including compressors, fans, and coils, for visible wear or damage. Loose connections or worn-out parts must be addressed immediately. -

Check for Leaks

Using a leak detector, technicians should confirm that no refrigerant or air leaks exist. This step ensures the system maintains proper pressure levels. -

Test Electrical Connections

Electrical connections should be tested for stability and proper voltage. Faulty wiring can lead to system malfunctions or safety hazards. -

Verify Vacuum Levels

The vacuum gauge should be checked to confirm the system has reached the desired vacuum level. Any deviations may indicate residual moisture or contaminants. -

Monitor System Performance

After reassembly, technicians should run the system to monitor airflow, temperature control, and overall performance. This step ensures the system operates as intended.

Reassembling the HVAC System

Reassembling the HVAC system requires precision to avoid introducing contaminants or causing damage. Technicians should follow these steps:

- Reconnect Components: Securely reconnect all components, including hoses, fittings, and electrical connections.

- Refill Refrigerant: Add the appropriate amount of refrigerant to the system, following manufacturer guidelines.

- Replace Covers and Panels: Reattach any covers or panels removed during maintenance to protect internal components.

- Conduct a Final Test: Power on the system and observe its operation. Ensure there are no unusual noises, vibrations, or performance issues.

Tip: Always document the maintenance process, including any repairs or replacements made. This record helps track system performance over time and simplifies future servicing.

Final Thoughts

Post-maintenance checks and system reassembly are vital for maintaining HVAC efficiency and reliability. By following these steps, technicians can ensure the system operates safely and meets performance expectations. Regular inspections not only extend the lifespan of HVAC systems but also provide a secure and comfortable environment for users.

Tips for Maximizing Vacuum Pump Efficiency

Regular Cleaning and Maintenance of the Pump

Regular cleaning and maintenance are essential for keeping vacuum pumps efficient and reliable. Technicians should inspect the pump for wear, leaks, or damage before and after each use. Cleaning the surrounding area ensures optimal airflow and prevents contaminants from entering the system. For pumps handling condensable vapors, activating the gas ballast helps remove moisture from the oil, improving performance.

Routine maintenance tasks include checking oil levels, replacing contaminated oil, and inspecting diaphragms and filters. A running hour meter can track operating hours, ensuring timely servicing. Additionally, purging the pump after use removes solvents and contaminants, extending its lifespan.

Tip: Never block the pump discharge outlet, as this can create back pressure and reduce efficiency.

Choosing the Right Model of the High Performance Vacuum Pump for Your Needs

Selecting the correct vacuum pump model ensures compatibility with HVAC system requirements. The High Performance Vacuum Pump Single-Stage 5 Pa Rotary Vane Economy Vacuum Pump offers multiple models tailored to different applications. To choose the right one, consider factors such as system capacity, pumping speed, and ultimate vacuum levels.

For smaller systems, a model like the VP115 with a 1.5CFM flow rate may suffice. Larger systems may require the VP2100, which provides a robust 10CFM flow rate. Noise levels, maintenance ease, and energy-saving features should also influence the decision. Balancing these factors ensures optimal performance and cost efficiency.

Pro Tip: Evaluate the system's air volume and pressure needs to avoid underperformance or energy waste.

Ensuring Proper Storage and Handling

Proper storage and handling protect vacuum pumps from damage and maintain their efficiency. Always follow manufacturer guidelines for handling and installation. Clean, dry hands or gloves prevent contaminants like dust and grease from interfering with operations. Using the correct tools during installation ensures proper fitting and prevents premature wear.

Store vacuum pumps in a controlled environment with stable temperature and humidity levels. Excess moisture can cause corrosion, while extreme temperatures may degrade materials. Protective packaging, such as sealed bags or cushioned containers, shields components from dust and physical impact.

Note: Avoid exposing pumps to direct sunlight or harsh chemicals, as these can degrade sensitive parts like rubber seals and gaskets.

Monitoring for Wear and Tear

Monitoring wear and tear in vacuum pumps is essential for ensuring their long-term efficiency and reliability. Regular checks help identify early signs of damage, allowing technicians to address issues before they escalate into costly repairs or system failures. By focusing on key reliability indicators, professionals can maintain optimal performance and extend the lifespan of their equipment.

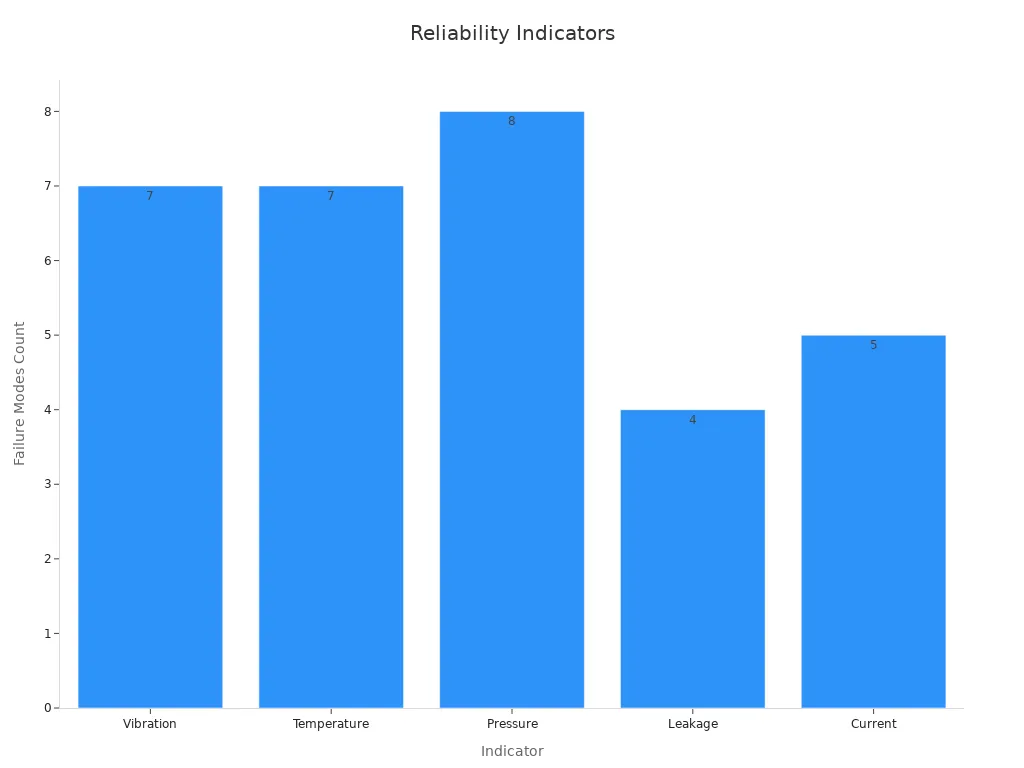

Key Reliability Indicators

Technicians should monitor specific indicators to detect wear and tear in vacuum pumps. These indicators provide valuable insights into the pump's condition and help pinpoint potential failure modes. The table below outlines the primary indicators and their associated failure modes:

| Indicator | Failure Mode |

|---|---|

| Vibration | Worn bearing, Lubrication issue, Misalignment, Cavitation, Blockage, Dry running, Unstable pressure |

| Temperature | Worn bearing, Lubrication issue, Contamination in bearing, Cavitation, Blockage, Dry running, Unstable pressure |

| Pressure | Outer seal, Inner seal, Pump casing, Blockage, Reduced performance, Cavitation, Erosion, Corrosion |

| Leakage | Outer seal, Inner seal, Blockage, Dry running |

| Current | Worn bearing, Lubrication issue, Cavitation, Blockage, Drive Motor issues |

Visualizing Failure Modes

The chart below illustrates the number of failure modes associated with each reliability indicator. This visualization highlights the importance of monitoring multiple parameters to ensure comprehensive maintenance.

Practical Tips for Monitoring

- Use Diagnostic Tools: Employ vibration analyzers, thermal cameras, and pressure gauges to track changes in key indicators.

- Set Baseline Measurements: Record initial readings when the pump is new to establish benchmarks for comparison.

- Schedule Regular Inspections: Conduct routine checks to identify gradual changes in performance.

- Log Observations: Maintain detailed records of readings and maintenance activities for future reference.

Tip: Address unusual vibrations or temperature spikes immediately to prevent further damage. Early intervention minimizes downtime and repair costs.

By consistently monitoring wear and tear, technicians can ensure that vacuum pumps operate efficiently and reliably, safeguarding HVAC systems from unexpected failures.

Common Mistakes to Avoid

Skipping System Preparation Steps

Skipping preparation steps often leads to inefficiencies and safety risks during HVAC maintenance. Proper preparation ensures technicians can work effectively and avoid damaging the system. Neglecting this phase can result in contamination, leaks, or incomplete vacuum processes.

Key preparation steps to follow:

- Disconnect the power supply to prevent electrical hazards.

- Inspect the workspace for cleanliness and ventilation.

- Seal tubing and pipework to block contaminants from entering the system.

- Use nitrogen purging to clear debris and moisture before brazing.

Tip: Always wear protective gear, such as gloves and safety glasses, to minimize exposure to harmful substances.

Technicians who skip these steps may face longer maintenance times and increased repair costs. Following preparation protocols ensures the system operates efficiently after servicing.

Using an Undersized or Overused Pump

Using an undersized or overused vacuum pump can compromise HVAC system performance. An undersized pump struggles to achieve the required vacuum level, leaving moisture and contaminants in the system. Overused pumps may experience wear and tear, reducing their efficiency and reliability.

Signs of an undersized or overused pump:

- Difficulty reaching the desired vacuum level.

- Unusual noises or vibrations during operation.

- Increased maintenance frequency due to component failure.

Pro Tip: Match the pump's capacity to the system's requirements. For smaller systems, models like the VP115 are ideal, while larger systems benefit from robust options like the VP2100.

Selecting the right pump model and monitoring its condition prevents downtime and ensures optimal performance.

Neglecting Regular Pump Maintenance

Regular maintenance keeps vacuum pumps functioning efficiently and extends their lifespan. Neglecting this routine can lead to clogged filters, contaminated oil, and worn-out components, all of which reduce the pump's effectiveness.

Maintenance tasks to prioritize:

- Inspect oil levels and replace contaminated oil promptly.

- Clean filters and diaphragms to prevent blockages.

- Check for leaks and wear in seals and hoses.

Note: Schedule inspections based on operating hours and usage intensity to catch issues early.

Technicians who neglect maintenance risk costly repairs and reduced system efficiency. Consistent upkeep ensures the vacuum pump operates at peak performance during HVAC servicing.

Failing to Monitor the Vacuum Process

Failing to monitor the vacuum process can lead to incomplete system evacuation, leaving moisture and contaminants behind. These residual elements compromise HVAC performance and increase the likelihood of system failures. Technicians must actively oversee the vacuum process to ensure the system reaches the desired vacuum level and remains free of impurities.

Risks of Neglecting Vacuum Monitoring

When technicians neglect to monitor the vacuum process, several issues may arise:

- Residual Moisture: Moisture left in the system can freeze, causing blockages and reducing efficiency.

- Contaminants: Non-condensable gases hinder heat exchange, leading to higher energy consumption.

- System Failures: Incomplete evacuation increases wear on components, shortening the system's lifespan.

Tip: Always use a reliable vacuum gauge to track pressure levels and confirm the system achieves the required vacuum depth.

Best Practices for Effective Monitoring

-

Use High-Quality Tools

Employ a vacuum gauge with precise readings to monitor pressure changes. A digital gauge provides better accuracy compared to analog models. -

Track Pressure Levels

Observe the vacuum gauge throughout the process. A steady decline in pressure indicates proper evacuation. If pressure stabilizes prematurely, inspect for leaks or blockages. -

Perform Leak Tests

After reaching the desired vacuum level, conduct a leak test using tracer gases like helium. This step ensures the system remains sealed and free of contaminants. -

Document the Process

Maintain a log of vacuum levels and test results. This record helps identify recurring issues and ensures compliance with maintenance standards.

Pro Tip: Allow the vacuum pump to run for an extended period to remove deep-seated moisture, especially in older systems.

By actively monitoring the vacuum process, technicians can prevent costly repairs and maintain HVAC efficiency. This attention to detail ensures the system operates at peak performance, providing long-term reliability and energy savings.

High-performance vacuum pumps are indispensable for maintaining HVAC systems. The High Performance Vacuum Pump Single-Stage 5 Pa Rotary Vane Economy Vacuum Pump ensures efficient removal of air and moisture, enhancing system performance and longevity.

In conclusion, the AC vacuum pump is essential for maintaining and repairing air conditioning systems. Its ability to remove moisture and contaminants from the system ensures efficient performance and prolongs the unit's lifespan.

Proper maintenance of vacuum pumps directly impacts the efficiency of HVAC components.

- Removes air and moisture from air conditioning systems.

- Improves AC system performance.

- Prevents damage to system components.

Regular use of these pumps reduces energy costs and prevents system failures, making them a vital tool for HVAC care.

FAQ

What is the primary purpose of a vacuum pump in HVAC systems?

A vacuum pump removes air, moisture, and contaminants from HVAC systems. This process ensures efficient heat exchange, prevents blockages caused by frozen moisture, and protects system components from corrosion or damage.

How often should vacuum pumps undergo maintenance?

Technicians should inspect vacuum pumps before and after each use. Regular maintenance, including oil changes and filter cleaning, ensures optimal performance. Following the manufacturer's guidelines for servicing intervals is essential for long-term reliability.

Can the High Performance Vacuum Pump handle industrial HVAC systems?

Yes, the High Performance Vacuum Pump Single-Stage 5 Pa Rotary Vane Economy Vacuum Pump offers models like the VP2100 with a 10CFM flow rate. This model is ideal for industrial-scale HVAC systems, ensuring efficient evacuation and system reliability.

Why is monitoring the vacuum process important?

Monitoring ensures the system reaches the desired vacuum level and remains free of contaminants. It prevents residual moisture, which can freeze and cause blockages, and ensures non-condensable gases do not hinder system efficiency.

How do I choose the right vacuum pump model for my HVAC system?

Consider the system's size, capacity, and vacuum requirements. Smaller systems may require models like the VP115, while larger systems benefit from higher-capacity options like the VP2100. Matching the pump to the system ensures efficiency and cost-effectiveness.

Tip: Always consult the product specifications to ensure compatibility with your HVAC system.