Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

How to Address Common HVAC Failures with a Universal Air Conditioning Controller

Universal air conditioning controllers offer homeowners rapid solutions for frequent HVAC failures. These devices enable users to identify and resolve issues directly, reducing the wait time for technical support. An air conditioning controller gives individuals the power to restore indoor comfort and manage repair costs efficiently.

Homeowners benefit from immediate control, improved reliability, and greater confidence in their HVAC systems.

Key Takeaways

- Universal air conditioning controllers help homeowners quickly find and fix common HVAC problems, saving time and money.

- These controllers improve comfort by keeping indoor temperatures stable and reducing energy use through smart control methods.

- Safety checks and following proper procedures are essential before troubleshooting HVAC systems to prevent injuries and damage.

- Using diagnostic codes and error messages from the controller makes it easier to identify issues and perform effective repairs.

- Regular maintenance and knowing when to call a professional ensure the HVAC system stays reliable and efficient over time.

Air Conditioning Controller: How It Solves Common HVAC Failures

Simplifying Troubleshooting and Repairs

An air conditioning controller streamlines the process of identifying and fixing HVAC problems. Homeowners often face challenges like unresponsive units, inconsistent temperatures, or frequent cycling. With a universal controller, they can quickly access diagnostic codes and error messages, which point directly to the source of the issue. This approach removes much of the guesswork from troubleshooting.

Many modern controllers, such as the Frequency Air Conditioner Inverter Control System PCB Board Remote, feature advanced signal processing and fault detection. These technologies allow users to spot problems early, sometimes before a complete system failure occurs. A scientific study found that smart Thermostat data can detect gradual capacity loss in air conditioners. This early warning system supports proactive maintenance, reducing the risk of unexpected breakdowns.

Case studies from various industries highlight the effectiveness of advanced controllers. For example, a manufacturing facility improved reliability and reduced downtime after installing modern control systems. Retail stores and office buildings also reported fewer emergency repairs and better comfort after upgrading to advanced HVAC controllers. These real-world examples show that a universal controller can make troubleshooting and repairs faster and more accurate.

Immediate Benefits for Homeowners

Homeowners experience several immediate advantages when using a universal air conditioning controller. The most noticeable benefit is cost savings. By optimizing energy use and reducing unnecessary service calls, these controllers help lower monthly bills and maintenance expenses.

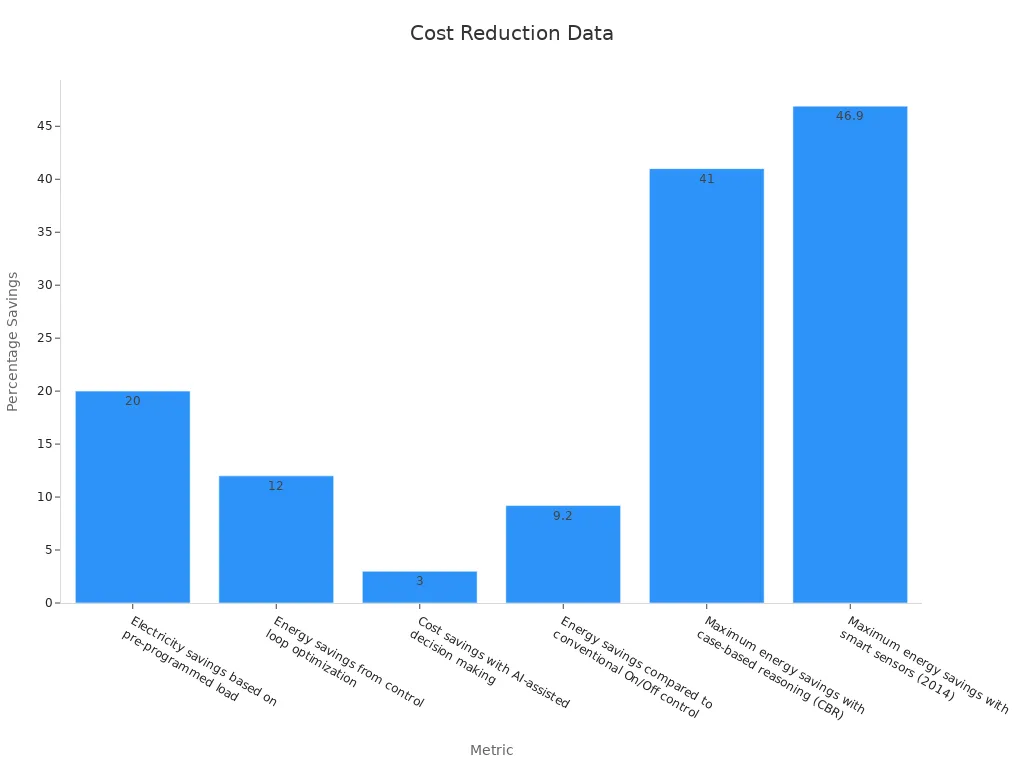

| Metric Description | Numerical Value |

|---|---|

| Electricity savings based on pre-programmed load | 20% |

| Energy savings from control loop optimization | 12% |

| Cost savings reported | Up to 60% |

| Energy savings maintaining thermal comfort | About 9% |

| Average energy savings (1997-2018) using AI tools | Around 14% |

| Energy savings range | 5% to 15% |

| Energy cost savings with demand-side management devices | Up to 40% |

| Heating and cooling energy reduction with fuzzy P control | Up to 20.1% |

| Cost savings with AI-assisted decision making | 3% |

| Energy savings compared to conventional On/Off control | 9.2% |

| Maximum energy savings with case-based reasoning (CBR) | 41% |

| Maximum energy savings with smart sensors (2014) | 46.9% |

| Electricity bill reduction | Around 10% |

Beyond savings, homeowners gain peace of mind. The controller’s built-in safety and emergency protection features help prevent damage during unexpected events. Users can also enjoy a more comfortable living space, as the controller maintains stable temperatures and airflow. These benefits make the air conditioning controller a valuable addition to any home.

Understanding a Universal Air Conditioning Controller

How the Controller Works

A universal air conditioning controller manages the operation of HVAC systems by using advanced control methods. These controllers often rely on three main types of control strategies:

- On-off control switches the system fully on or off when the temperature crosses a set point. This method works well for simple temperature adjustments.

- Proportional control adjusts the output power based on how far the current temperature is from the desired set point. This approach reduces overshooting and frequent cycling.

- PID (Proportional-Integral-Derivative) control combines three actions to provide precise and stable temperature regulation. The controller automatically tunes its parameters to match the system’s needs, ensuring accurate performance even as conditions change.

Controllers like the Frequency Air Conditioner Inverter Control System PCB Board Remote use these principles to deliver consistent comfort. PID controllers, for example, maintain stable temperatures in processes such as drying, curing, and baking, showing their effectiveness in demanding environments.

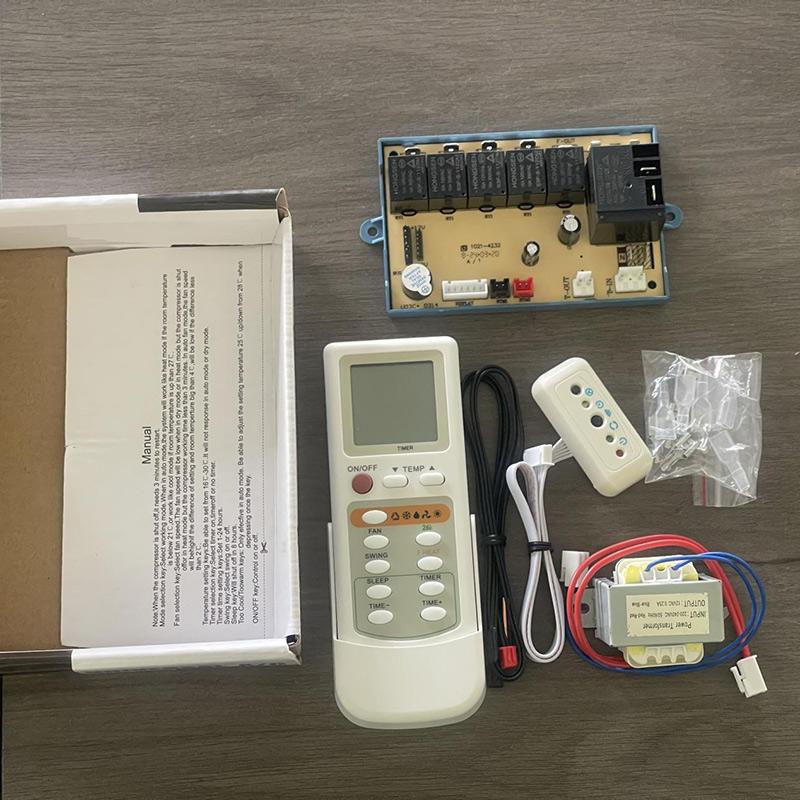

Key Features and Compatibility

Universal controllers stand out for their flexibility and adaptability. Most models support a wide range of air conditioning units, including hanging, cabinet, and ceiling machines. The modular structure allows users to add or upgrade components, such as drainage pumps or sensors, through dedicated interfaces. This design makes it easy to expand system capabilities without major hardware changes.

A typical operational workflow includes:

- Improving metadata quality for accurate system monitoring

- Detecting and fixing both hard and soft faults

- Implementing occupant-centric controls to enhance comfort

- Monitoring energy flows and key performance indicators (KPIs)

Real-world data from commercial buildings shows that correcting control faults can lead to significant energy savings, sometimes up to 35%. These improvements highlight the value of a universal controller in both residential and commercial settings.

Safety and Reliability

Safety and reliability remain top priorities for any air conditioning controller. Independent organizations, such as the AMCA and CSA Group, certify products through rigorous testing and ongoing monitoring. These certifications ensure that controllers meet strict safety and performance standards. The AMCA Certified Ratings Program, for example, verifies product claims through laboratory testing and public challenge mechanisms. The CSA Group evaluates controllers for compliance with international safety standards and functional safety requirements.

Consumer surveys also show high reliability scores for certified HVAC systems over many years of use. These results give homeowners and facility managers confidence that their controllers will perform dependably and safely in real-world conditions.

Common HVAC Failures Addressed by an Air Conditioning Controller

AC Unit Not Turning On

Many homeowners encounter situations where the air conditioning unit fails to start. This issue often results from electrical faults, sensor errors, or control board malfunctions. An air conditioning controller can quickly identify the root cause by displaying diagnostic codes or error messages. Users can check for common triggers such as tripped breakers, loose wiring, or faulty sensors. In many cases, the controller’s built-in fault detection and emergency protection features help prevent further damage by shutting down the system safely.

Tip: Always inspect the power supply and remote batteries before troubleshooting deeper electrical components.

Recent studies show that HVAC systems experience frequent faults. For example:

- Fault Detection and Diagnostics (FDD) technology reports an average of three faults per Air Handling Unit (AHU) and one fault per Air Terminal Unit (ATU) each month.

- The most common fault for AHUs involves supply air temperature setpoint issues, affecting over half of the units at some point.

- Sensor, valve, and damper faults persist for a significant portion of the monitoring period.

Not Cooling or Heating Properly

Improper cooling or heating often signals underlying problems such as restricted airflow, leaky ducts, or incorrect temperature settings. The controller monitors key performance metrics, including temperature differentials, airflow, and energy consumption.

- A temperature differential of 22 degrees or more in cooling mode may indicate inadequate airflow or a malfunctioning unit.

- For heating, a temperature rise below 25 degrees can signal failure, especially in electric furnaces.

- Outlet air temperatures above 140 degrees may point to airflow problems and uneven heating.

IoT sensors and real-time alerts help users detect performance degradation early. Improper installation or leaky ducts can increase household energy use for heating and cooling by up to 30%. Monitoring these metrics allows the controller to maintain comfort and efficiency.

Short Cycling Issues

Short cycling occurs when the HVAC system turns on and off too frequently. This pattern stresses components and reduces system lifespan. Common causes include oversized equipment, thermostat placement errors, or sensor faults. The controller’s advanced algorithms detect abnormal cycling patterns and adjust settings to restore normal operation.

- Persistent faults, such as valve cycling and sensor calibration issues, appear in over 20% of monitored equipment.

- Short cycling often results from unresolved sensor or control faults, which the controller can identify and address.

By addressing these failures, the air conditioning controller improves reliability and extends the life of HVAC systems.

Incorrect Temperature Readings

Incorrect temperature readings often create confusion and discomfort in homes and businesses. Sensors inside HVAC systems can drift over time, leading to inaccurate measurements. Even a small error, such as one degree, can increase energy consumption by more than 8.5%. Over several years, this inefficiency can result in significant financial losses and higher carbon emissions. Some sensors maintain their accuracy for a decade, while others begin to drift almost immediately after installation.

When a system reports the wrong temperature, it may overcool or undercool the space. This not only wastes energy but also puts extra strain on the equipment. In large facilities like data centers, where cooling accounts for up to 40% of total energy use, small measurement errors can have a massive impact on operational costs and equipment reliability.

Tip: Regularly calibrate temperature sensors and check for dust or debris that may affect readings. Many modern controllers offer self-diagnosis features to alert users when a sensor drifts out of range.

A universal controller helps address these issues by providing real-time monitoring and alerts. Users can quickly identify and correct sensor problems, ensuring the system maintains accurate temperature control and optimal efficiency.

Unresponsive or Faulty Controls

Unresponsive or faulty controls present another common challenge in HVAC systems. Users may notice that the remote control fails to change settings, or the unit does not respond to temperature adjustments. Sometimes, the remote displays false alarms or error messages. These symptoms often point to communication problems between the sensors and the control board.

A table below summarizes typical signs of unresponsive controls:

| Symptom | Possible Cause |

|---|---|

| Remote does not change settings | Sensor communication failure |

| False alarms on remote | Control board malfunction |

| No response to temperature changes | Faulty wiring or connections |

Technicians recommend checking the batteries in the remote and ensuring there are no obstructions between the remote and the unit. If problems persist, the controller’s diagnostic features can help pinpoint the source of the issue. Quick identification and resolution of control faults prevent unnecessary downtime and maintain comfort in the space.

Step-by-Step Troubleshooting with an Air Conditioning Controller

Safety Checks Before You Start

Safety forms the foundation of every HVAC troubleshooting process. Before working with any air conditioning controller, technicians and homeowners must follow a series of essential safety protocols. These steps help prevent injuries and reduce the risk of equipment damage.

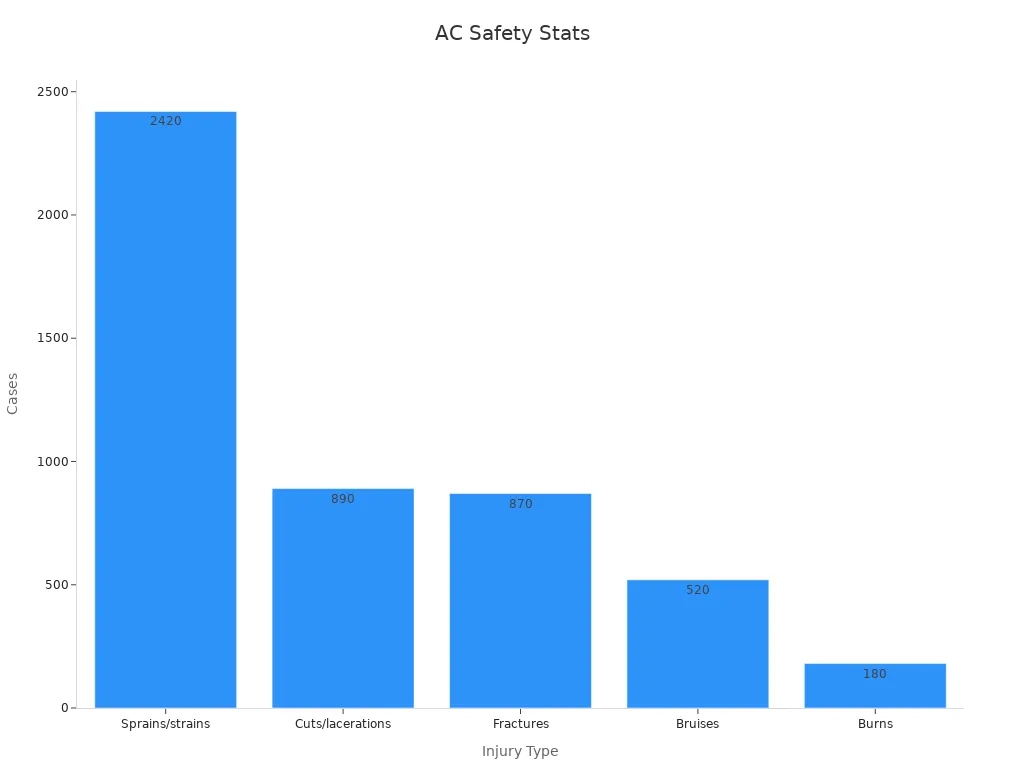

| Safety Protocol Aspect | Description / Protocols | Incident Reduction Support / Statistics |

|---|---|---|

| Pre-Job Preparations | Verify technician training and certification; assess job site hazards; identify confined spaces | Addresses risks from insufficient training and unknown hazards, reducing accidents caused by lack of knowledge and hazards |

| Personal Protective Equipment | Use safety glasses, gloves, respiratory protection, hearing protection, flame-resistant clothing | Minimizes injuries from electrical shocks, chemical exposure, refrigerant leaks, and falls |

| Electrical Safety | Follow lockout/tagout procedures; confirm de-energized circuits; proper wiring and connections | Reduces electrical shock and arc flash incidents, which are common causes of HVAC accidents |

| Refrigerant Safety | Follow EPA handling regulations; inspect for leaks; avoid inhalation and skin contact | Prevents injuries related to refrigerant exposure, a noted cause of accidents |

| Working at Heights | Use harnesses, lanyards; safe ladder placement | Mitigates fall-related injuries, a significant source of HVAC technician accidents |

| Chemical Handling | Use PPE; work in ventilated areas; proper storage and labeling | Reduces chemical burns and exposure incidents |

| Equipment Inspection | Check for wear, damage, malfunction; ensure safety guards are in place | Prevents equipment-related injuries and malfunctions |

| Manufacturer Guidelines | Follow installation and maintenance standards | Ensures safe operation and reduces system failures that could cause accidents |

| Incident Statistics (2020) | Sprains/strains (2420 cases), cuts/lacerations (890), fractures (870), bruises (520), burns (180) | Highlights the types of injuries that safety protocols aim to reduce |

| Common Accident Causes | Electrical shocks, refrigerant leaks, falls, chemical exposure, burns, musculoskeletal injuries, training | Emphasizes the need for comprehensive safety training and adherence to protocols |

The US Bureau of Labor Statistics reports that HVAC technicians often experience sprains, strains, cuts, fractures, bruises, and burns. Electrical hazards, refrigerant leaks, falls, and chemical exposure cause most of these injuries. Regular safety training and strict adherence to protocols significantly reduce these incidents.

Before starting any troubleshooting, technicians should:

- Inspect the HVAC system installation for correct placement and compliance with manufacturer requirements.

- Observe and document equipment operation, including startup and shutdown sequences.

- Report any system issues to contractors immediately.

- Perform Testing, Adjusting, and Balancing (TAB) to calibrate the system for optimal performance.

Technicians must also complete safety checklists, de-energize equipment, and use lockout/tagout procedures. Power should be turned off at the breaker panel, and circuits tested with properly rated meters. Proper use of personal protective equipment (PPE) and tool inspection further enhance safety.

⚠️ Tip: Never skip safety checks. Even experienced technicians can overlook hazards without a checklist.

Resetting and Reprogramming the Controller

Resetting and reprogramming an air conditioning controller often resolves many common issues. These procedures restore the controller to its default settings and clear any temporary faults or errors.

A typical reset process involves:

- Turn off the power to the HVAC system at the breaker panel.

- Wait at least 60 seconds to allow the system to fully power down.

- Restore power and observe the controller’s startup sequence.

- Use the remote or onboard buttons to initiate a factory reset if available.

Reprogramming the controller may require entering specific codes or following a sequence of button presses. This process updates the controller’s software or restores its original configuration. In automotive systems, similar reset procedures clear learned data and resolve operational issues. Although the process may differ for HVAC systems, the principle remains the same: resetting and reprogramming can resolve stuck settings, communication errors, and performance problems.

🔄 Note: Always consult the manufacturer’s manual for model-specific reset and reprogramming instructions.

Using Diagnostic Codes and Error Messages

Modern air conditioning controllers display diagnostic codes and error messages to help users identify problems quickly. These codes appear on the controller’s display or remote, providing valuable information about system status.

Common steps for using diagnostic codes include:

- Refer to the controller’s manual for a list of error codes and their meanings.

- Observe the code displayed during system startup or when a fault occurs.

- Match the code to the corresponding issue, such as sensor failure, communication error, or power supply problem.

- Follow the recommended troubleshooting steps for each code.

Some controllers offer advanced features, such as real-time alerts and self-diagnosis. These functions help users detect issues early and take corrective action before a minor problem becomes a major failure.

| Error Code Example | Possible Cause | Recommended Action |

|---|---|---|

| E1 | Indoor sensor fault | Check and replace sensor |

| E2 | Outdoor sensor fault | Inspect wiring and sensor |

| E3 | Communication error | Reset controller, check cables |

| E4 | Overload protection | Inspect power supply, restart |

💡 Tip: Keep a printed copy of the error code chart near the HVAC unit for quick reference during troubleshooting.

A well-designed air conditioning controller simplifies the troubleshooting process by providing clear, actionable information. Users can resolve many issues without waiting for a technician, saving time and reducing downtime.

Adjusting Settings for Best Performance

Optimizing air conditioning settings can transform both comfort and efficiency in any space. Technicians and homeowners often overlook the impact of precise adjustments, yet these small changes can deliver significant results. By fine-tuning temperature setpoints, fan speeds, and operational schedules, users can achieve a balance between energy savings and occupant comfort.

Key improvements from precise controller adjustments include:

- Improved energy efficiency by preventing unnecessary system operation and reducing energy waste.

- Targeted maintenance, as analytics help identify and resolve issues before they escalate, minimizing downtime and operating costs.

- Enhanced installation optimization by detecting improper sensor placement or equipment sizing, which boosts overall system performance.

- Fine-tuned smart control settings that maintain comfort while minimizing energy consumption.

- Correction of faulty Variable Air Volume (VAV) operation, which reduces downtime and maintains indoor environmental quality.

These benefits lead to lower operating costs, reduced carbon emissions, and a healthier indoor environment.

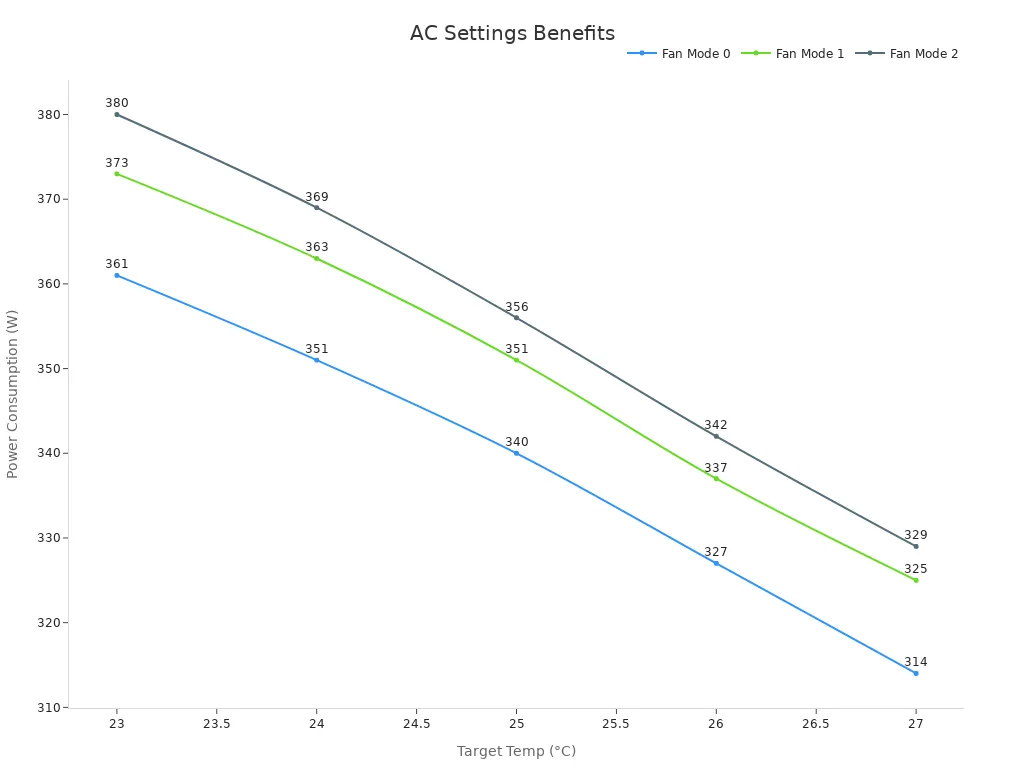

A recent case study highlights the value of optimal setting adjustments. The study compared different target temperatures and fan modes, measuring their effects on power consumption, comfort, and system performance. The table below summarizes the findings:

| Case No. | Target Temperature (°C) | Fan Mode | Predicted Indoor Temperature (°C) | Predicted Humidity (rh) | Average Power Consumption (W) | PMV Index | Fitness Value |

|---|---|---|---|---|---|---|---|

| 1 | 23 | 0 | 22.69 | 62 | 361 | -2.04 | 565 |

| 2 | 24 | 0 | 22.89 | 62 | 351 | -1.96 | 547 |

| 3 | 25 | 0 | 23.00 | 62 | 340 | -1.91 | 531 |

| 4 | 26 | 0 | 23.10 | 62 | 327 | -1.86 | 513 |

| 5 | 27 | 0 | 23.20 | 62 | 314 | -1.82 | 496 |

| 6 | 23 | 1 | 22.24 | 62 | 373 | -2.25 | 598 |

| 7 | 24 | 1 | 22.49 | 62 | 363 | -2.14 | 577 |

| 8 | 25 | 1 | 22.73 | 62 | 351 | -2.02 | 553 |

| 9 | 26 | 1 | 22.91 | 62 | 337 | -1.95 | 532 |

| 10 | 27 | 1 | 23.07 | 62 | 325 | -1.88 | 513 |

| 11 | 23 | 2 | 22.06 | 62 | 380 | -2.33 | 613 |

| 12 | 24 | 2 | 22.24 | 62 | 369 | -2.25 | 594 |

| 13 | 25 | 2 | 22.51 | 62 | 356 | -2.12 | 568 |

| 14 | 26 | 2 | 22.78 | 62 | 342 | -2.00 | 542 |

| 15 | 27 | 2 | 23.01 | 62 | 329 | -1.90 | 519 |

The data shows that setting the target temperature to 27°C with the lowest fan mode (Case 5) results in the lowest power consumption (314 W) and the best fitness value (496), while still maintaining acceptable comfort levels. Adjusting these parameters, especially during the initial cooling phase, can significantly reduce energy use.

Technicians recommend reviewing and adjusting controller settings at the start of each season. Regular calibration and monitoring ensure that the system operates at peak efficiency. Smart controllers with analytics capabilities can automate many of these adjustments, further enhancing performance and comfort.

💡 Tip: Small changes in temperature setpoints and fan speeds can lead to noticeable savings on energy bills without sacrificing comfort.

Knowing When to Call a Professional

While many HVAC issues can be resolved through careful troubleshooting and adjustment, certain situations require the expertise of a licensed technician. Recognizing these scenarios helps prevent further damage and ensures the safety of both the equipment and the occupants.

Consider contacting a professional if any of the following occur:

- The system displays persistent error codes that do not clear after a reset.

- Electrical components show signs of damage, such as burnt wires or tripped breakers.

- Refrigerant leaks are suspected, indicated by hissing sounds or a noticeable drop in cooling performance.

- The unit emits unusual odors, smoke, or excessive noise during operation.

- Temperature or humidity levels remain unstable despite repeated adjustments.

- The controller fails to respond to any input, even after battery replacement and reset procedures.

A professional technician possesses the tools and training to diagnose complex electrical or refrigerant issues. They can also ensure compliance with safety regulations and manufacturer guidelines. Attempting to repair advanced faults without proper knowledge may void warranties or create safety hazards.

⚠️ Alert: Always prioritize safety. If unsure about any step or if the system behaves unpredictably, seek professional assistance immediately.

Routine maintenance visits from certified professionals also help extend the lifespan of HVAC systems. These experts can perform deep diagnostics, clean internal components, and update firmware, ensuring reliable operation throughout the year.

Quick-Reference Air Conditioning Controller Troubleshooting Checklist

Immediate Actions to Take

A quick response can prevent minor HVAC issues from becoming major failures. When troubleshooting, users should follow a systematic approach to ensure safety and efficiency. Start by turning off the power at the breaker panel before inspecting any components. Check the remote batteries and confirm that the display works. Inspect the air filter and replace it if dirty. Examine the thermostat settings and ensure the temperature is set correctly.

Regular electrical testing and monitoring of motor amperage help identify developing problems early. Users should listen for unusual noises or vibrations and look for visible signs of wear or damage. Preventive maintenance, such as cleaning condenser and evaporator coils, supports optimal performance. Scheduling routine inspections and documenting any changes in system behavior can help catch issues before they escalate.

🛠️ Tip: For most residential and commercial systems, an eight-hour, five-day response time for repairs is sufficient. However, critical environments may require faster action or 24/7 coverage.

A checklist for immediate troubleshooting includes:

- Power off the unit and check all electrical connections.

- Replace or clean air filters.

- Inspect for unusual noises, odors, or vibrations.

- Verify thermostat calibration and settings.

- Monitor refrigerant levels and look for leaks.

- Clean and check the condensate drain system.

Signs That Require Professional Help

Some warning signs indicate the need for a licensed HVAC technician. Persistent malfunctions or safety hazards should never be ignored. Users should watch for:

- Unusual noises such as hissing, clanging, or buzzing.

- Inconsistent temperature control or inability to maintain set temperatures.

- Sudden increases in energy bills, which may signal malfunctioning pumps or valves.

- Visible damage to the unit or electrical wiring.

- Erratic behavior after power outages, including failure to restart.

- Overheating compressors or electrical irregularities.

Homeowners should document symptoms, actions taken, and system conditions before shutdown. This information assists professionals in diagnosing and repairing the system efficiently. Regular inspection of filters, ductwork, electrical components, and refrigerant levels helps identify early warning signs and supports preventive maintenance.

⚠️ Alert: If safety concerns arise, such as overheating or electrical issues, stop troubleshooting and contact a professional immediately.

An Air Conditioning Controller gives homeowners the tools to address HVAC failures quickly. They can restore comfort, save time, and avoid unnecessary service calls. Users follow clear steps to troubleshoot common issues. The right controller keeps the system running smoothly. Homeowners experience less stress and greater control over their indoor environment.

A reliable controller helps maintain comfort and efficiency throughout the year.

FAQ

How does a universal air conditioning controller improve HVAC reliability?

A universal controller, such as the Frequency Air Conditioner Inverter Control System PCB Board Remote, uses advanced fault detection and emergency protection. These features help prevent unexpected breakdowns and maintain stable operation in both residential and commercial environments.

Can homeowners install a universal air conditioning controller themselves?

Most universal controllers offer user-friendly installation. However, for optimal safety and performance, a certified technician should handle wiring and initial setup. This approach ensures compliance with manufacturer guidelines and local codes.

What types of air conditioning units are compatible with universal controllers?

Universal controllers support a wide range of systems, including hanging, cabinet, and ceiling units. The modular design allows easy integration with PG motors, electric heating, and additional peripherals. Users can upgrade or expand their systems as needed.

How do diagnostic codes help with troubleshooting?

Diagnostic codes appear on the controller’s display or remote. These codes identify specific faults, such as sensor errors or communication failures. Users can reference the manual or a quick chart to take targeted action and resolve issues efficiently.

Is regular maintenance still necessary with a universal controller?

Yes. Regular maintenance, such as cleaning filters and checking connections, remains essential. The controller’s monitoring features help detect issues early, but routine inspections by professionals ensure long-term system health and efficiency.