Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

How Dual Gauge Valve Enhances HVAC System Efficiency

Efficient HVAC systems depend on tools that ensure accurate pressure monitoring and control. The Dual Gauge valve for HVAC/Refrigeration offers a streamlined solution by integrating high-pressure and low-pressure monitoring into a single device. This innovation reduces tool-switching time and optimizes system diagnostics. Its advanced bidirectional pressure monitoring minimizes energy waste, helping technicians enhance system performance while lowering operational costs. By combining precision and durability, the valve becomes an essential component for maintaining HVAC system efficiency.

Key Takeaways

- Dual gauge valves help HVAC systems by checking both high and low pressure in one tool. This saves time and works better.

- These valves keep pressure steady, cutting energy waste. This lowers costs and makes the system work well.

- Using dual gauge valves often can make HVAC equipment last longer. They reduce damage by keeping pressure balanced.

- Picking the right valve means looking at pressure limits, strong materials, and if it works with refrigerants.

- Installing and taking care of these valves the right way keeps them working well and avoids expensive fixes.

Dual Gauge Valve for HVAC/Refrigeration: What It Is and How It Works

Definition and Features of a Dual Gauge Valve

A dual gauge valve is a specialized tool designed to enhance the efficiency of HVAC and refrigeration systems. It integrates high-pressure (HP) and low-pressure (LP) monitoring into a single, compact unit. This design eliminates the need for multiple tools, reducing the time required for system diagnostics and maintenance. The valve features dual 1/4" SAE ports, allowing technicians to monitor bidirectional pressures up to 600 PSI (42 kg/cm²) with precision.

Advanced models include digital displays that provide dual-scale readings in PSI and kg/cm², along with temperature readouts in °C. These features eliminate errors associated with analog scales, ensuring accurate data interpretation. Constructed from corrosion-resistant brass and high-strength polymers, the valve withstands harsh environments while maintaining long-term reliability. Its multifunctional design supports tasks such as vacuum testing, refrigerant selection, and system purging, making it indispensable for HVAC professionals.

Role of Dual Gauge Valves in HVAC and Refrigeration Systems

Dual gauge valves play a critical role in maintaining the performance and safety of HVAC and refrigeration systems. By consolidating HP and LP monitoring, they enable technicians to perform real-time diagnostics with minimal effort. This capability is essential for identifying issues such as refrigerant leaks, blockages, or undercharge conditions.

In HVAC systems, the valve ensures that pressure levels remain within optimal ranges, preventing energy waste and equipment strain. For refrigeration systems, it helps maintain the correct refrigerant flow, ensuring consistent cooling performance. The valve's ability to handle both high and low pressures makes it versatile for various applications, including automotive AC servicing and industrial refrigeration diagnostics.

Importance of Bidirectional Pressure Monitoring

Bidirectional pressure monitoring is vital for ensuring the efficiency and safety of modern HVAC systems. It allows technicians to measure both HP and LP simultaneously, providing a comprehensive view of system performance. This capability simplifies the detection of pressure imbalances, which can lead to energy inefficiencies or equipment damage if left unaddressed.

For example, maintaining proper differential pressure is crucial in applications like room static and stairwell pressurization. In room static systems, accurate pressure control ensures safety and optimal performance. In stairwell pressurization, maintaining positive pressure prevents smoke infiltration during emergencies, enhancing occupant safety. The dual gauge valve's ability to monitor bidirectional pressures in real-time makes it an essential tool for achieving these outcomes.

| Application | Importance |

|---|---|

| Room Static | Maintaining proper differential pressure is critical for safety and performance in spaces. |

| Stairwell Pressurization | Ensures a smoke-free environment during emergencies by maintaining positive pressure. |

By integrating bidirectional pressure monitoring into a single device, the dual gauge valve for HVAC/Refrigeration streamlines diagnostics and enhances system reliability. This innovation not only improves operational efficiency but also reduces the risk of costly downtime.

Efficiency Benefits of Dual Gauge Valves in HVAC Systems

Precise Pressure Monitoring for Enhanced Performance

The Dual Gauge Valve for HVAC/Refrigeration offers unparalleled precision in pressure monitoring, a critical factor in optimizing system performance. By enabling simultaneous high-pressure (HP) and low-pressure (LP) readings, it provides technicians with a comprehensive view of system dynamics. This real-time data allows for immediate adjustments, ensuring that HVAC systems operate within their optimal pressure ranges.

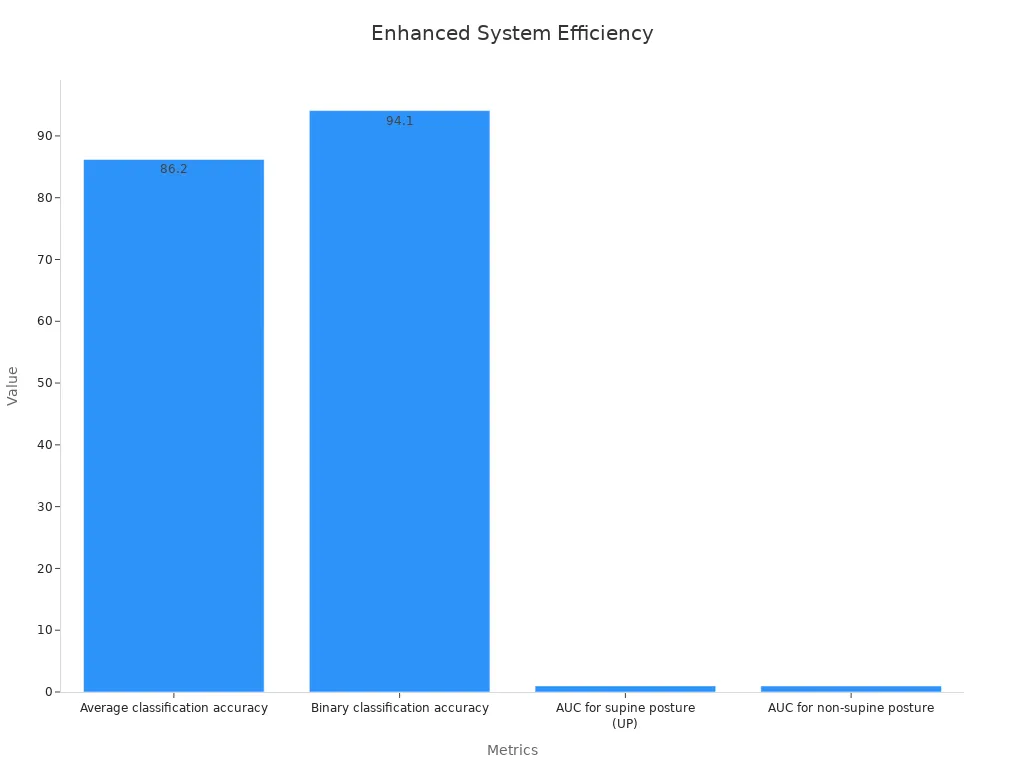

Statistical evidence highlights the impact of precise pressure monitoring on system efficiency. For instance, experimental data demonstrates an average classification accuracy of 86.2% and a binary classification accuracy of 94.1% when using advanced diagnostic tools like dual gauge valves. These metrics underscore the valve's ability to deliver reliable and actionable insights.

This level of precision not only enhances performance but also minimizes the risk of misdiagnosis, which can lead to costly repairs or inefficiencies. The valve's ability to maintain consistent operation across various applications makes it an indispensable tool for HVAC professionals.

Reducing Energy Waste Through Accurate Regulation

Energy efficiency remains a top priority in HVAC system management. The Dual Gauge Valve for HVAC/Refrigeration plays a pivotal role in reducing energy waste by ensuring accurate pressure regulation. By maintaining the correct pressure levels, the valve prevents overloading and underperformance, both of which contribute to unnecessary energy consumption.

The following table illustrates the measurable improvements linked to the use of dual gauge valves:

| Improvement Type | Description |

|---|---|

| Energy Efficiency | DRVs significantly enhance energy efficiency and contribute to cost savings in commercial buildings. |

| Temperature Control | They ensure consistent temperatures and optimal system performance across various applications. |

| System Balancing | DRVs help balance water flow in HVAC systems, ensuring all parts of the building receive the right amount of heating or cooling. |

| Reliability | By maintaining system reliability, DRVs reduce the frequency of repairs and lower maintenance costs. |

| Consistent Operation | DRVs play a crucial role in system balancing by adjusting to maintain specified flow rates even as pressure changes across the system. |

Accurate regulation also extends the lifespan of HVAC components by reducing wear and tear caused by pressure fluctuations. This not only lowers operational costs but also aligns with sustainability goals by minimizing energy waste.

Streamlining Diagnostics and Maintenance Tasks

The multifunctional design of the Dual Gauge Valve for HVAC/Refrigeration simplifies diagnostics and maintenance tasks. By integrating HP and LP monitoring into a single device, it eliminates the need for multiple tools, reducing tool-switching time by up to 40%. This efficiency allows technicians to focus on identifying and resolving issues more quickly.

The valve's advanced diagnostic features enable the detection of common problems such as refrigerant leaks, blockages, and undercharge conditions. These capabilities streamline maintenance workflows, ensuring that systems remain operational with minimal downtime. Additionally, digital models with dual-scale displays provide instant, error-free readings, further enhancing the speed and accuracy of diagnostics.

Technicians benefit from the valve's robust construction, which withstands harsh conditions often encountered in commercial and industrial settings. Its durability ensures long-term reliability, making it a cost-effective investment for HVAC professionals.

Additional Advantages of Using Dual Gauge Valves

Cost Savings Through Improved Efficiency

Dual gauge valves offer significant cost savings by enhancing HVAC system efficiency. Their precise pressure monitoring ensures optimal system performance, reducing energy consumption and lowering utility bills. By consolidating multiple tools into one device, technicians save time during diagnostics and maintenance, which translates into reduced labor costs.

Tip: Businesses can achieve up to 20% energy savings annually by maintaining proper pressure levels in HVAC systems.

The valve's ability to detect issues like refrigerant leaks or blockages early prevents costly repairs. This proactive approach minimizes the risk of major system failures, further contributing to financial savings. For commercial buildings, these savings can accumulate into thousands of dollars annually, making the dual gauge valve a cost-effective investment.

Extending Equipment Lifespan with Accurate Monitoring

Accurate pressure monitoring plays a crucial role in extending the lifespan of HVAC equipment. Dual gauge valves maintain consistent pressure levels, reducing wear and tear on system components. This prevents premature failure of critical parts such as compressors and condensers.

A well-maintained system operates more efficiently and lasts longer. For example, maintaining proper pressure levels can extend the lifespan of a compressor by several years. The valve's durable construction, featuring corrosion-resistant brass and high-strength polymers, ensures long-term reliability even in harsh environments.

Note: Regular use of dual gauge valves for diagnostics can increase the average lifespan of HVAC systems by 15–20%.

Reducing Downtime and Maintenance Costs

Minimizing system downtime is essential for both residential and commercial HVAC applications. Dual gauge valves streamline diagnostics, enabling technicians to identify and resolve issues quickly. This reduces the time systems remain offline, ensuring uninterrupted operation.

The valve's advanced diagnostic features, such as real-time bidirectional pressure monitoring, allow for early detection of potential problems. Addressing these issues promptly reduces the frequency of emergency repairs, lowering overall maintenance costs. Additionally, the robust design of the valve ensures fewer replacements, further cutting expenses.

Key Insight: Businesses that prioritize preventive maintenance using dual gauge valves experience 30% fewer system breakdowns annually.

By reducing downtime and maintenance costs, dual gauge valves enhance operational efficiency and reliability, making them indispensable for HVAC professionals.

Selecting and Maintaining Dual Gauge Valves for Optimal Efficiency

Key Factors to Consider When Choosing a Dual Gauge Valve

Selecting the right dual gauge valve ensures optimal performance and long-term reliability. Several factors should guide this decision:

- Pressure and Temperature Ratings: Ensure the valve matches the system's operating pressure and temperature requirements. For example, the Taojun HVAC Dual Gauge Valve supports pressures up to 600 PSI (42 kg/cm²), making it suitable for most HVAC applications.

- Material Durability: Choose valves constructed from corrosion-resistant materials like brass or stainless steel. These materials withstand harsh environments and extend the valve's lifespan.

- Compatibility: Verify that the valve is compatible with the refrigerants and fittings used in the system. The 1/4" SAE ports on the Taojun HVAC valve ensure broad compatibility.

- Diagnostic Features: Opt for valves with advanced features such as digital displays for precise readings. These features enhance accuracy and simplify diagnostics.

- Ease of Installation: Select a valve designed for straightforward installation and maintenance. Accessibility and clear flow direction markings are essential for efficient setup.

By considering these factors, technicians can ensure the valve meets the specific demands of their HVAC systems.

Best Practices for Installation and Maintenance

Proper installation and maintenance are critical for maximizing the efficiency and reliability of dual gauge valves. Follow these guidelines to achieve optimal results:

- Confirm the valve's compatibility with the system's pressure and temperature ratings.

- Clear the installation site of debris to prevent contamination.

- Mount the valve in an accessible location, aligning it with the flow direction indicated by the arrow.

- Secure the valve using gaskets and bolts, tightening them evenly to avoid leaks.

- Adjust the valve spindle to control the flow rate, using flow meters or pressure gauges for precision.

- Test for leaks after installation and verify flow rates and pressures.

- Perform regular maintenance, including leak testing and calibration, to ensure consistent performance.

Additionally, establish a preventive maintenance schedule. Replace worn components such as seals and gaskets promptly. Training maintenance personnel on proper valve operation further enhances reliability and longevity.

Avoiding Common Mistakes to Ensure Long-Term Reliability

Certain mistakes can compromise the performance and lifespan of dual gauge valves. Avoid these common issues to maintain reliability:

- Improper Sealing: Ensure the valve disc seals correctly against the check seat. Misalignment can lead to leaks and inefficiencies.

- Debris Contamination: Keep the valve free from dirt and debris, which can obstruct the disc and seat, causing malfunctions.

- Restricted Movement: Regularly inspect the valve components to prevent restrictions in movement, which can impair functionality.

By addressing these potential pitfalls, technicians can prevent system failures and extend the valve's operational life. Proper care and attention to detail ensure the dual gauge valve remains a dependable tool for HVAC applications.

Dual gauge valves transform HVAC system management by delivering precise pressure control and reducing energy waste. Their streamlined design simplifies maintenance tasks, saving time and resources. These valves also enhance system reliability, extend equipment lifespan, and lower operational costs. Selecting the right Dual Gauge Valve for HVAC/Refrigeration and adhering to proper maintenance practices ensures maximum efficiency. This investment benefits both residential and commercial applications, making it indispensable for technicians seeking optimal system performance.

FAQ

1. What is the primary purpose of a dual gauge valve in HVAC systems?

The dual gauge valve enables simultaneous monitoring of high-pressure (HP) and low-pressure (LP) levels. This functionality ensures precise pressure control, which optimizes system performance, reduces energy waste, and prevents equipment strain.

2. How does bidirectional pressure monitoring improve HVAC efficiency?

Bidirectional pressure monitoring provides real-time data on both HP and LP levels. This comprehensive view allows technicians to detect imbalances quickly, ensuring systems operate within optimal ranges. It minimizes energy waste and extends equipment lifespan.

3. Can the dual gauge valve be used with all refrigerants?

Yes, most dual gauge valves, including the Taojun HVAC Dual Gauge Valve, are compatible with common refrigerants. Always verify compatibility with the specific refrigerant type used in your system to ensure optimal performance.

4. What maintenance practices ensure the longevity of a dual gauge valve?

Regular maintenance includes leak testing, calibration, and inspecting seals for wear. Technicians should also clean the valve to prevent debris buildup and replace worn components promptly. Following these practices ensures consistent performance and reliability.

5. Why is the Taojun HVAC Dual Gauge Valve a good investment for technicians?

The Taojun HVAC Dual Gauge Valve consolidates multiple tools into one device, saving time and reducing costs. Its durable construction, advanced diagnostic features, and compatibility with various systems make it an indispensable tool for HVAC professionals.

Tip: Regular use of the valve for diagnostics can prevent costly repairs and extend system life.