Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

FOB China Port Pricing Guide: Copper Fittings for US Commercial Refrigeration Projects

FOB Copper Fittings play a crucial role in the efficiency and reliability of US commercial refrigeration systems. These fittings ensure proper connections in refrigeration pipelines, contributing to optimal performance and durability. Understanding FOB pricing is essential for businesses aiming to source these components cost-effectively. By analyzing the costs associated with Free on Board (FOB) transactions, companies can make informed purchasing decisions and maximize their budget. This approach allows buyers to evaluate supplier pricing transparently while considering shipping and handling expenses.

Key Takeaways

- Talk with suppliers to get better prices and payment deals. Use market knowledge to help your case.

- Pick trustworthy suppliers for good quality and on-time delivery. Check their certifications and visit their factories.

- Simplify shipping plans to save on transport costs. Make sure paperwork is correct and items are packed well.

- Buy in large amounts to get discounts and cheaper prices. Plan storage space and predict how much you’ll need.

- Save money by combining shipments and working with skilled freight companies for lower rates.

Key Components of FOB Pricing

Understanding the key components of FOB pricing is essential for businesses sourcing copper fittings from China. Each cost element contributes to the final price and impacts the overall budget for US commercial refrigeration projects. Below is a detailed breakdown of these components.

Product Costs

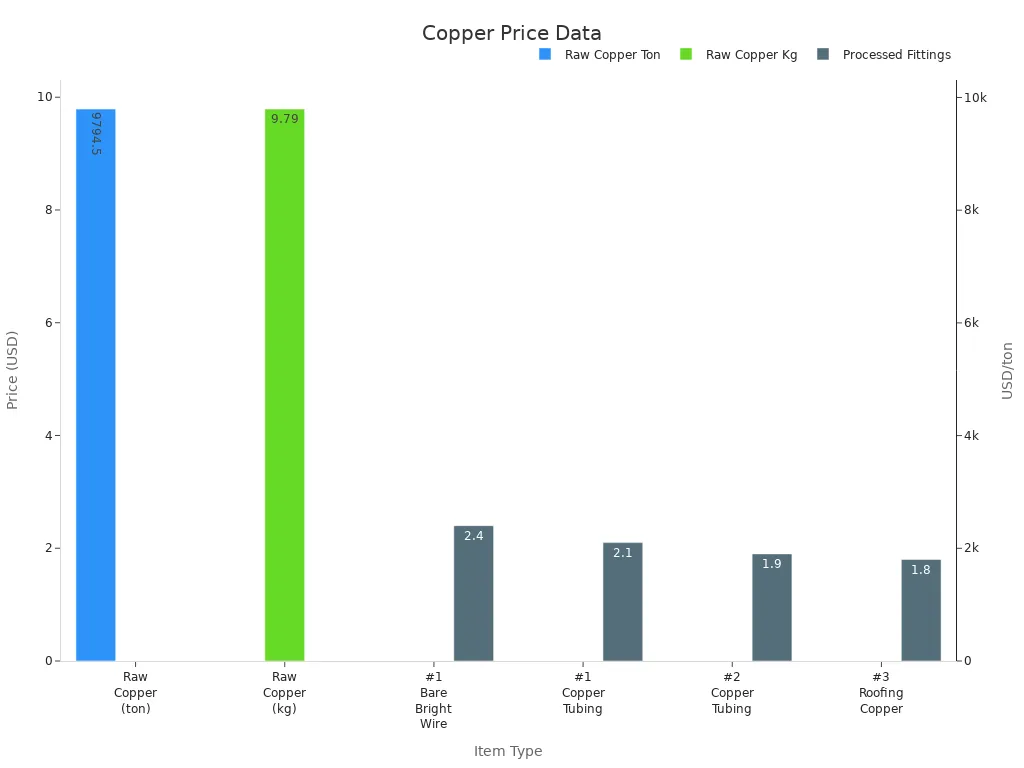

Product costs form the foundation of FOB pricing. These costs include the raw materials, manufacturing expenses, and labor required to produce copper fittings. Copper, as the primary material, significantly influences the cost due to its market volatility.

- Significant fluctuations in copper prices were observed during the Period of Investigation (POI). For example:

- The total Cost of Manufacturing (COM) for seamless refined Copper Pipe and tube products varied byover 25% between the highest and lowest quarterly costs.

- This volatility directly impacts the pricing of FOB copper fittings, as manufacturers adjust their prices to reflect changes in raw material costs.

The current market prices for raw copper and processed copper fittings further highlight this variability:

| Item | Price (USD) |

|---|---|

| Raw Copper (per ton) | 9,794.50 |

| Raw Copper (per kg) | 9.79 |

| #1 Bare Bright Wire | 2.40/lb |

| #1 Copper Tubing | 2.10/lb |

| #2 Copper Tubing | 1.90/lb |

| #3 Roofing Copper | 1.80/lb |

Manufacturers must carefully monitor these market trends to maintain competitive pricing while ensuring profitability.

Packaging and Handling

Packaging and handling costs are another critical component of FOB pricing. These costs cover the materials and labor required to prepare copper fittings for shipment. Proper packaging ensures the products remain intact during transit, reducing the risk of damage and subsequent losses.

- Common packaging materials include:

- Wooden crates for bulk shipments.

- Protective wraps and cushioning for smaller quantities.

- Handling costs may vary depending on the complexity of the packaging process and the labor rates in the manufacturing region.

Efficient packaging not only protects the products but also optimizes shipping space, reducing overall freight costs. Businesses sourcing FOB copper fittings should evaluate the packaging methods used by suppliers to ensure cost-effectiveness and product safety.

Port Fees and Documentation

Port fees and documentation costs are integral to FOB pricing. These expenses cover the administrative and logistical processes required to ship copper fittings from China to the US. Key elements include:

- Port Fees: Charges for using port facilities, including loading and unloading services.

- Documentation Costs: Expenses related to preparing export documents, such as bills of lading, certificates of origin, and customs declarations.

The Department of Commerce emphasizes the importance of correlating production costs with final sales prices. While direct traceability is not mandatory, a reasonable connection between these costs and the FOB price ensures transparency and compliance with international trade regulations.

Businesses must account for these fees when calculating the total cost of sourcing FOB copper fittings. Partnering with experienced suppliers can help streamline the documentation process and minimize delays at the port.

Factors Influencing FOB Copper Fittings Prices

Copper Market Trends

The copper market is highly dynamic, with pricing trends influenced by geopolitical and economic factors. Tariffs and trade wars, such as those seen during the Trump administration, have historically disrupted the copper plumbing and HVAC fittings market. These policy shifts often lead to price fluctuations and supply chain challenges. In Latin America, political instability and inconsistent regulations further contribute to market volatility, impacting the cost of FOB copper fittings.

Recent statistics highlight key trends shaping the market. For example, Shanghai copper inventories have risen by 24.6%, while refined copper production reached 2.34 million metric tons in November. However, a deficit of 131,000 metric tons in refined copper underscores the ongoing supply-demand imbalance. Additionally, China's copper imports increased by 17.8% year-on-year, reflecting robust demand. These trends emphasize the importance of monitoring global market conditions when sourcing copper fittings.

Manufacturing and Labor Costs

Manufacturing and labor costs play a pivotal role in determining FOB pricing. In China, the cost of producing copper fittings depends on factors such as raw material availability, energy prices, and workforce wages. Efficient manufacturing processes and advanced technologies can help reduce production expenses, enabling suppliers to offer competitive prices.

Labor costs in China remain relatively low compared to other countries, making it an attractive sourcing destination for copper fittings. However, rising wages and stricter labor regulations may gradually increase production costs. Businesses must consider these factors when evaluating supplier quotes to ensure cost-effectiveness without compromising quality.

Supply Chain and Global Demand

Global supply chain disruptions significantly influence the demand and pricing of copper fittings. Peru, a major copper supplier, faces production challenges, with approximately 30% of its output at risk. This disruption has contributed to rising copper prices as global demand continues to grow. The International Copper Study Group (ICSG) notes that only two major copper mines were developed between 2017 and 2021, limiting supply expansion.

The green energy sector is a key driver of copper demand, with the International Energy Agency (IEA) predicting a 45% increase by 2040. As industries transition to sustainable technologies, the need for copper fittings in refrigeration and HVAC systems will likely rise. Businesses sourcing FOB copper fittings must account for these supply chain dynamics to secure reliable and cost-effective solutions.

Calculating Total Costs for Copper Fittings

Step-by-Step FOB Pricing Calculation

Calculating the total cost of FOB copper fittings requires a systematic approach. Businesses must account for all cost components to avoid unexpected expenses. Below is a step-by-step guide to help buyers estimate their costs accurately:

-

Determine Product Costs:

Start by obtaining a detailed quote from the supplier. This quote should include the cost of the copper fittings, packaging, and handling. For example, if the supplier quotes $2.10 per pound for #1 copper tubing, multiply this by the total weight of the order. -

Add Port Fees and Documentation Costs:

Include charges for port services, such as loading and unloading, and the preparation of export documents. These costs vary depending on the port and the complexity of the shipment. -

Calculate Freight Costs:

Obtain shipping rates from freight forwarders. Rates depend on factors like shipment volume, weight, and destination. For instance, shipping a 20-foot container from Ningbo to Los Angeles may cost between $1,500 and $2,000. -

Include Tariffs and Import Duties:

Research applicable tariffs and duties for copper fittings imported into the US. Use the Harmonized Tariff Schedule (HTS) to identify the correct classification and duty rate. -

Account for Miscellaneous Expenses:

Add any additional costs, such as insurance or inspection fees, to the total. These expenses ensure the shipment's safety and compliance with regulations.

By following these steps, businesses can calculate the total cost of sourcing FOB copper fittings and make informed purchasing decisions.

Shipping Costs to the US

Shipping costs play a significant role in the overall expense of importing copper fittings. These costs depend on several factors, including the shipping method, container size, and destination port. Buyers typically choose between Full Container Load (FCL) and Less than Container Load (LCL) shipping options.

-

FCL Shipping:

This option is ideal for large orders. A 20-foot container can hold approximately 44,000 pounds of copper fittings, while a 40-foot container accommodates up to 88,000 pounds. FCL shipping offers lower per-unit costs but requires a higher upfront investment. -

LCL Shipping:

For smaller orders, LCL shipping allows businesses to share container space with other shipments. While the per-unit cost is higher, this option reduces the financial burden for smaller-scale purchases.

Tip: To minimize shipping costs, businesses should consolidate orders and optimize container utilization. Partnering with experienced freight forwarders can also help negotiate better rates and streamline logistics.

Tariffs and Import Duties

Tariffs and import duties significantly impact the final cost of copper fittings. These charges are imposed by the US government to regulate trade and protect domestic industries. Buyers must understand the applicable rates to avoid unexpected expenses.

-

Harmonized Tariff Schedule (HTS):

Copper fittings are classified under specific HTS codes. For example, seamless copper pipes and tubes may fall under HTS code 7411.10.1030, which carries a duty rate of 3%. Buyers should consult the HTS database to confirm the correct classification. -

Section 301 Tariffs:

Additional tariffs may apply to products imported from China under Section 301 of the Trade Act. These tariffs range from 7.5% to 25%, depending on the product category. -

Exemptions and Refunds:

Some products may qualify for tariff exemptions or refunds under specific trade agreements. Businesses should explore these options to reduce costs.

By factoring in tariffs and duties, buyers can accurately estimate the landed cost of FOB copper fittings and plan their budgets effectively.

Tips for Optimizing Costs

Negotiating with Suppliers

Effective negotiation with suppliers can significantly reduce costs when sourcing FOB copper fittings. Buyers should begin by researching market trends and understanding the supplier's pricing structure. This knowledge provides leverage during discussions. Requesting detailed quotes that break down costs, including raw materials, labor, and packaging, ensures transparency.

Building long-term relationships with suppliers often leads to better pricing. Suppliers may offer discounts for consistent orders or bulk purchases. Additionally, buyers can negotiate favorable payment terms, such as extended credit periods, to improve cash flow. Clear communication and a collaborative approach foster trust, making suppliers more willing to accommodate cost-saving requests.

Selecting Reliable Chinese Suppliers

Choosing the right supplier is critical for cost optimization. Reliable suppliers ensure consistent quality and timely delivery, reducing the risk of delays or additional expenses. Businesses should evaluate potential suppliers based on their certifications, production capabilities, and client reviews. For instance, companies like Ningbo Taojun Refrigeration Equipment Co., Ltd. have established reputations for producing high-quality refrigeration components and maintaining international certifications.

Conducting factory audits provides valuable insights into a supplier's operations. Buyers should assess manufacturing processes, quality control measures, and compliance with environmental and labor standards. Partnering with suppliers who prioritize innovation and efficiency often results in competitive pricing and superior products.

Efficient Logistics Management

Streamlined logistics management minimizes costs associated with shipping and handling. Businesses should focus on metrics such as on-time delivery, accurate documentation, and proper packaging. The following table highlights key logistics performance metrics and corrective actions to enhance efficiency:

| Metric | Issue Description | Corrective Actions |

|---|---|---|

| Accurate and timely documentation | Errors in shipping documentation lead to delays. | Implement mandatory documentation training, invest in document management software, develop templates. |

| Proper packaging | Packaging issues lead to damage and delays. | Develop packaging guidelines, provide training, implement WMS system, ensure adequate materials. |

| Correct labeling | Incorrect shipping labels lead to delivery errors. | Implement double-checking system, utilize barcode technology, improve workspace organization. |

| On-time delivery | Shipments are delivered at scheduled times. | Analyze delivery time performance against ETA, track on-time delivery rates. |

| Traceability and tracking | Real-time location and traceability of shipments. | Monitor transit times, analyze service failures, ensure accurate tracking systems. |

| On-time shipping | Data on shipment departure dates and times. | Validate shipment departure, measure scheduled delivery dates, assess carrier performance. |

By addressing these areas, businesses can reduce delays, prevent damage, and optimize shipping costs. Partnering with experienced freight forwarders further enhances logistics efficiency, ensuring smooth transportation of FOB copper fittings.

Bulk Purchasing Strategies

Bulk purchasing offers a practical approach to reducing costs when sourcing copper fittings for US commercial refrigeration projects. By ordering larger quantities, businesses can leverage economies of scale and negotiate better pricing with suppliers.

Benefits of Bulk Purchasing

- Lower Unit Costs: Suppliers often provide discounts for bulk orders, reducing the per-unit price of copper fittings. This strategy benefits businesses with high-volume requirements.

- Reduced Shipping Expenses: Consolidating shipments into fewer containers minimizes freight costs. Full Container Load (FCL) shipping becomes more cost-effective compared to Less than Container Load (LCL) options.

- Improved Supplier Relationships: Regular bulk orders foster long-term partnerships with suppliers. These relationships often lead to preferential treatment, such as priority production scheduling or exclusive discounts.

Tip: Businesses should calculate their storage capacity and forecast demand before committing to bulk purchases. Excess inventory can lead to unnecessary holding costs.

Strategies for Effective Bulk Purchasing

- Forecast Demand Accurately: Analyze historical sales data and market trends to estimate future requirements. Accurate forecasting prevents overstocking or underordering.

- Negotiate Volume Discounts: Request tiered pricing structures from suppliers. For example, a supplier may offer a 5% discount for orders exceeding 10,000 units and a 10% discount for orders above 20,000 units.

- Collaborate with Freight Forwarders: Partner with logistics providers to optimize container utilization. Efficient packing and shipping reduce transportation costs.

- Plan Storage Solutions: Ensure adequate warehouse space for bulk inventory. Proper storage prevents damage and maintains product quality.

Example of Bulk Pricing

| Order Quantity | Discount Rate | Unit Price (USD) | Total Cost (USD) |

|---|---|---|---|

| 5,000 units | 0% | 2.10 | 10,500 |

| 10,000 units | 5% | 2.00 | 20,000 |

| 20,000 units | 10% | 1.90 | 38,000 |

Bulk purchasing requires careful planning and execution. Businesses must balance cost savings with operational efficiency to maximize the benefits of this strategy.

Understanding FOB pricing is crucial for businesses sourcing copper fittings for US refrigeration projects. It allows buyers to evaluate costs transparently and make informed decisions that align with their budgets.

Key Takeaways for Cost Optimization:

- Negotiate Effectively: Buyers should leverage market insights to secure better pricing and payment terms.

- Choose Reliable Suppliers: Partnering with certified manufacturers ensures consistent quality and timely delivery.

- Streamline Logistics: Efficient shipping and packaging reduce unnecessary expenses.

- Consider Bulk Purchases: Larger orders often lead to significant discounts and lower unit costs.

Pro Tip: Businesses can maximize savings by consolidating shipments and collaborating with experienced freight forwarders.

📩 Ready to source copper fittings? Explore trusted suppliers like Ningbo Taojun Refrigeration Equipment Co., Ltd. or request quotes today to start optimizing your procurement strategy.

FAQ

1. What does FOB mean in the context of copper fittings?

FOB, or Free on Board, indicates that the seller delivers the goods to a specified port. The buyer assumes responsibility for shipping, insurance, and import duties from that point onward. This term simplifies cost allocation in international trade.

2. How can businesses identify reliable Chinese suppliers?

Buyers should evaluate suppliers based on certifications, production capacity, and client reviews. Conducting factory audits and verifying compliance with international standards ensures quality and reliability. Partnering with established companies like Ningbo Taojun Refrigeration Equipment Co., Ltd. minimizes risks.

3. Are there cost advantages to sourcing copper fittings from China?

Yes, China offers competitive pricing due to lower labor costs and efficient manufacturing processes. Bulk purchasing and favorable supplier relationships further enhance cost savings. Buyers should also consider logistics and tariffs when calculating total expenses.

4. How do copper market trends affect FOB pricing?

Copper price fluctuations directly impact FOB pricing. Global demand, supply chain disruptions, and geopolitical factors influence raw material costs. Buyers must monitor these trends to anticipate price changes and negotiate effectively with suppliers.

5. What are the benefits of bulk purchasing copper fittings?

Bulk purchasing reduces unit costs and shipping expenses. It also strengthens supplier relationships, often leading to priority production and exclusive discounts. Businesses should forecast demand accurately and ensure adequate storage to maximize these benefits.

Tip: Collaborating with freight forwarders can optimize container utilization and further reduce shipping costs.