Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

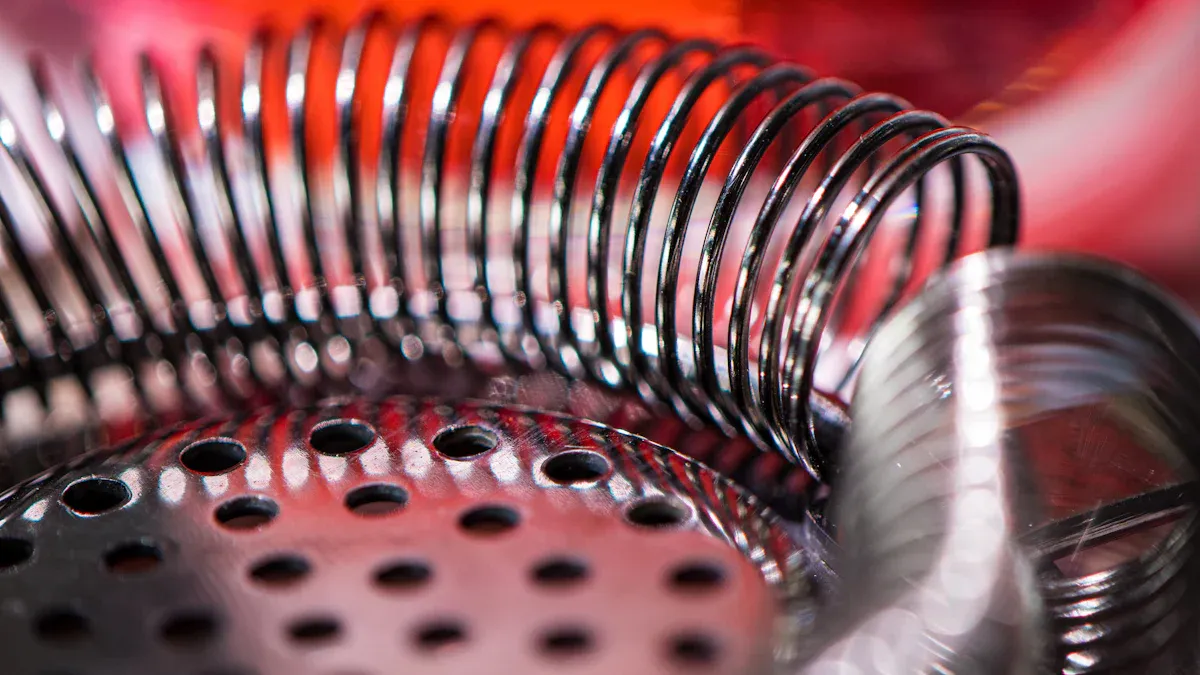

Finned Tube Condenser Steel Wire Spacing: 4mm vs. 6mm Efficiency Test for R134a Systems

The efficiency test results reveal that the 4mm steel wire spacing performs better than the 6mm spacing in R134a systems. This finding matters because tighter spacing enhances heat transfer in the Cooling Refrigerator Finned Tube Type Wire Tube Condenser. Improved efficiency reduces energy consumption, offering significant benefits for refrigeration systems used in commercial and residential applications.

Key Takeaways

- 4mm wire spacing helps transfer heat better. This cools faster and uses less energy, making it great for busy refrigeration systems.

- 6mm wire spacing works for systems with less use. It costs less but cools slower and uses more energy.

- Cleaning and checking condensers often is very important. Taking care of them avoids problems and makes them last longer.

Cooling Refrigerator Finned Tube Type Wire Tube Condenser Overview

Role in R134a Systems

The Cooling Refrigerator Finned Tube Type Wire Tube Condenser plays a critical role in the operation of R134a refrigeration systems. It facilitates the heat exchange process by dissipating heat absorbed from the refrigerant during the cooling cycle. This component ensures that the refrigerant transitions back to its liquid state efficiently, maintaining optimal system performance. Its design, which includes finned tubes and wire spacing, maximizes surface area for heat transfer. This makes it an essential part of both commercial and residential refrigeration units.

R134a systems rely on this condenser to maintain energy efficiency and consistent cooling. The condenser's ability to handle high thermal loads directly impacts the system's overall reliability. By optimizing the design of the Cooling Refrigerator Finned Tube Type Wire Tube Condenser, manufacturers can enhance the performance of R134a systems, reducing energy consumption and operational costs.

Impact of Steel Wire Spacing on Efficiency

Steel wire spacing significantly influences the efficiency of the Cooling Refrigerator Finned Tube Type Wire Tube Condenser. Tighter wire spacing, such as 4mm, increases the surface area available for heat dissipation. This results in improved thermal conductivity and faster cooling cycles. Conversely, wider spacing, like 6mm, reduces the surface area, which can lead to slower heat transfer and decreased efficiency.

The choice of wire spacing affects not only the condenser's performance but also the energy consumption of the entire refrigeration system. Systems with optimized wire spacing operate more efficiently, reducing strain on the compressor and extending the lifespan of the equipment. For R134a systems, selecting the appropriate wire spacing is crucial for achieving the best balance between performance and energy savings.

Efficiency Test Setup and Methodology

Test Conditions

The efficiency test for R134a systems was conducted under controlled conditions to ensure accurate and repeatable results. The following steps outline the test setup:

- The ambient air temperature in the controlled room was set to five specific levels: 10°C, 15°C, 20°C, 25°C, and 30°C. Each temperature was stabilized before testing began.

- A 310 L tank filled with mains water was used, starting at an initial temperature of 20°C. The room was locked to prevent external disturbances.

- A DT80 data logger was initialized remotely to record data from thermocouples and pressure transducers.

- The heat pump was activated remotely, and the test continued until the electronic controller detected a full heat-up cycle. This occurred when the top four tank sensors reached 60°C, and the bottom sensor reached 50°C.

- After the test, the DT80 data logger was stopped, and the data were extracted. Its memory was cleared before the next test.

These conditions ensured that the performance of the Cooling Refrigerator Finned Tube Type Wire Tube Condenser could be evaluated consistently across different scenarios.

Evaluation Metrics

The evaluation of efficiency relied on precise measurements and advanced instrumentation. The experimental setup included a compressor, condenser, evaporator, expansion device (TXV), and SLHX. The following tools and metrics were used:

- T-type thermocouples and pressure gauges measured thermodynamic properties.

- A mass flow meter recorded the refrigerant mass flow rate.

- A power meter tracked the compressor's power consumption.

- A mass scale measured the refrigerant mass charge.

The uncertainties in compressor work and cooling capacity were calculated at 2.26% and 4.72%, respectively. These metrics provided a comprehensive understanding of the condenser's performance, ensuring reliable comparisons between the 4mm and 6mm wire spacing configurations.

Results and Analysis

4mm Spacing Performance

The 4mm wire spacing demonstrated superior performance during the efficiency test. This configuration provided a larger surface area for heat dissipation, which enhanced thermal conductivity. The increased contact between the refrigerant and the condenser's surface allowed for faster heat transfer. As a result, the system achieved quicker cooling cycles and reduced energy consumption.

The test data revealed that the 4mm spacing maintained consistent performance across all ambient temperature levels. Even at higher temperatures, the condenser efficiently dissipated heat, ensuring the refrigerant returned to its liquid state without overburdening the compressor. This stability contributed to the overall reliability of the R134a system.

Additionally, the tighter spacing minimized the formation of thermal resistance. This design feature allowed the Cooling Refrigerator Finned Tube Type Wire Tube Condenser to operate at peak efficiency, making it an ideal choice for applications requiring high thermal loads.

6mm Spacing Performance

The 6mm wire spacing, while functional, exhibited lower efficiency compared to the 4mm configuration. The wider spacing reduced the available surface area for heat exchange, which slowed the rate of thermal conductivity. This limitation resulted in longer cooling cycles and increased energy consumption.

At higher ambient temperatures, the 6mm spacing struggled to maintain consistent performance. The reduced heat dissipation capacity placed additional strain on the compressor, potentially shortening its lifespan. Despite these challenges, the 6mm spacing performed adequately in environments with moderate thermal loads.

This configuration may still be suitable for applications where energy efficiency is not the primary concern. However, its limitations make it less favorable for high-demand systems.

Comparative Analysis

The comparison between the 4mm and 6mm wire spacing highlighted the advantages of tighter spacing in the Cooling Refrigerator Finned Tube Type Wire Tube Condenser. The 4mm spacing consistently outperformed the 6mm configuration in terms of thermal conductivity, cooling cycle duration, and energy efficiency.

| Metric | 4mm Spacing | 6mm Spacing |

|---|---|---|

| Heat Dissipation | High | Moderate |

| Cooling Cycle Duration | Short | Longer |

| Energy Consumption | Lower | Higher |

| Compressor Strain | Minimal | Increased |

| Performance at High Temps | Stable | Inconsistent |

The table above summarizes the key differences between the two configurations. The 4mm spacing's ability to handle high thermal loads and maintain efficiency under varying conditions makes it the preferred choice for R134a systems. In contrast, the 6mm spacing may be more suitable for low-demand applications where cost considerations outweigh performance requirements.

Practical Recommendations

Application-Specific Choices

Selecting the appropriate wire spacing for a Cooling Refrigerator Finned Tube Type Wire Tube Condenser depends on the specific application and operational requirements. Systems requiring high efficiency and consistent performance, such as commercial refrigeration units or industrial cooling systems, benefit significantly from the 4mm wire spacing. This configuration offers superior heat dissipation, shorter cooling cycles, and reduced energy consumption, making it ideal for environments with high thermal loads.

In contrast, the 6mm wire spacing may suit applications where energy efficiency is less critical. For instance, residential refrigerators or low-demand cooling systems can utilize this configuration effectively. Its lower manufacturing cost and adequate performance in moderate thermal conditions make it a practical choice for budget-conscious projects.

The choice of refrigerant also plays a crucial role in determining the condenser's efficiency. Studies show that R134a exhibits a Coefficient of Performance (COP) approximately 5.4% higher than R1234yf, 8.6% higher than R452A, and 0.6% higher than R454C. This positions R134a as a strong candidate for systems prioritizing efficiency.

| Refrigerant Mix | Coefficient of Performance (COP) | Refrigeration Capacity | Compressor Work | Condenser Capacity |

|---|---|---|---|---|

| R134a | Baseline | Baseline | Baseline | Baseline |

| R152a | Higher COP | Higher Capacity | Lower Work | Higher Capacity |

| R134a/R152a - 30/70 | Comparable | Comparable | Comparable | Comparable |

| R134a/R152a - 10/90 | Comparable | Comparable | Comparable | Comparable |

This data underscores the importance of evaluating refrigerant properties alongside wire spacing to optimize system performance.

Maintenance and Longevity Factors

Proper maintenance is essential for ensuring the long-term efficiency and reliability of finned tube condensers. Regular cleaning of the condenser's surface prevents the accumulation of dust and debris, which can obstruct airflow and reduce heat transfer efficiency. For systems operating in dusty or industrial environments, more frequent cleaning schedules are recommended.

Routine inspections of the steel wires and fins help identify signs of wear or corrosion. Tighter wire spacing, such as 4mm, may require more meticulous cleaning due to its denser structure. However, its enhanced thermal performance often offsets the additional maintenance effort.

Lubricating moving parts, such as the compressor, and monitoring refrigerant levels also contribute to the system's longevity. Over time, refrigerant leaks or imbalances can strain the condenser, reducing its efficiency. Addressing these issues promptly ensures stable operation and minimizes repair costs.

Tip: Using high-quality refrigerants like R134a can further enhance the lifespan of the condenser. Its superior thermodynamic properties reduce compressor strain and improve overall system stability.

Finally, selecting materials resistant to corrosion and wear, such as high-grade steel, extends the condenser's service life. Manufacturers like Ningbo Taojun Refrigeration Equipment Co., Ltd. prioritize innovative designs and durable materials to deliver reliable products that meet diverse customer needs.

By combining proper maintenance practices with application-specific choices, users can maximize the efficiency and longevity of their Cooling Refrigerator Finned Tube Type Wire Tube Condensers.

The 4mm wire spacing outperformed the 6mm configuration in efficiency tests, offering faster cooling cycles and lower energy consumption. For high-demand applications, the 4mm spacing is ideal.

Recommendation: Use 6mm spacing for low-demand systems prioritizing cost savings. Regular maintenance ensures optimal performance and extends the condenser's lifespan.

FAQ

What is the primary advantage of 4mm wire spacing in condensers?

The 4mm wire spacing provides a larger surface area for heat transfer. This improves thermal conductivity, reduces cooling cycles, and enhances energy efficiency in high-demand applications.

Can 6mm wire spacing still be effective in refrigeration systems?

Yes, 6mm wire spacing works well in low-demand systems. It offers adequate performance for residential refrigerators or budget-conscious projects where energy efficiency is less critical.

How does regular maintenance impact condenser performance?

Routine maintenance prevents dust buildup, ensures optimal airflow, and reduces thermal resistance. This extends the condenser's lifespan and maintains its efficiency over time.

Tip: Clean the condenser regularly and inspect for wear to avoid performance issues.