Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

Enhancing HVAC Performance with High-Quality Copper Capillary Tubes

What type of copper tubing is used for air conditioning and refrigeration? Copper capillary tubes are a key component in modern HVAC systems, designed to optimize refrigerant flow and enhance thermal efficiency. Their serpentine design minimizes resistance, significantly improving the Coefficient of Performance (COP). Research indicates that incorporating nanoparticles into refrigerants can boost cooling effectiveness by up to 15% when used alongside copper tubes. The HVAC industry depends on copper tubing for its exceptional durability, corrosion resistance, and ability to ensure long-term system reliability. These tubes also meet the increasing demand forenergy-efficient solutions, making them essential for sustainable building practices.

Key Takeaways

- Copper capillary tubes improve refrigerant flow, making HVAC systems cooler.

- Good copper tubes use less energy, cutting costs and pollution.

- Copper lasts long and resists rust, needing fewer repairs.

- Correct size and setup of tubes stop system problems and work best.

- Checking copper tubes often finds damage or clogs, keeping flow steady.

The Role of Capillary Tubes in HVAC Systems

What Are Capillary Tubes and How Do They Work?

Capillary tubes are narrow, precision-engineered copper tubes that play a vital role in HVAC systems. These tubes regulate refrigerant flow by utilizing pressure differences within the system. As refrigerant enters the capillary tube, its pressure drops due to friction and density changes, causing a reduction in temperature. This process ensures that the refrigerant reaches the evaporator in the correct state for optimal cooling performance.

Non-adiabatic capillary tubes, such as the capillary tube-suction line heat exchanger (CT-SLHX), further enhance system efficiency. By ensuring only vapor enters the compressor, these tubes prevent issues like slugging and improve thermal energy transfer. The lateral configuration of non-adiabatic tubes is particularly effective, offering superior manufacturability and performance. This design reduces refrigerant enthalpy, boosting cooling capacity and ensuring consistent system operation.

Why Are Capillary Tubes Critical for Refrigerant Flow Regulation?

Capillary tubes are indispensable for maintaining efficient refrigerant flow in HVAC systems. Their ability to adjust flow rates based on pressure changes eliminates the need for moving parts, enhancing reliability. Proper sizing of the tube is crucial to match the compressor's pumping capacity. Incorrect sizing can lead to inefficiencies, such as low suction pressure or flooding, which compromise system performance.

- Key Technical Benchmarks:

- Capillary tubes rely on pressure differences to regulate refrigerant flow.

- Optimal efficiency occurs at specific high- and low-side pressures.

- Proper tube sizing prevents issues like evaporator starvation or compressor strain.

The table below highlights common symptoms of capillary tube issues and their impact on system performance:

| Symptom of Capillary Tube Issue | Resulting Effect on System Performance |

|---|---|

| High head pressure from blockage | Starvation of the evaporator, leading to low pressures on the low side and high evaporator superheats |

| Complete blockage | Dangerously high head pressures and evaporator pressures in the vacuum range |

| Moisture causing freezing | Elevated head pressures and reduced evaporator pressures due to partial restriction, potentially leading to compressor shutdown |

Applications of Capillary Tubes in Air Conditioning and Refrigeration

Capillary tubes are widely used in air conditioning and refrigeration systems due to their ability to handle two-phase refrigerant flow efficiently. Studies have shown that parameters like condenser and evaporator pressures, refrigerant flow rate, and tube diameter significantly influence capillary tube performance. Computational models validate these findings, demonstrating how flow structures and evaporation dynamics affect system efficiency.

- Key Applications:

- Homogeneous flow of two-phase refrigerants in adiabatic capillary tubes.

- Empirical correlations for predicting refrigerant mass flow rates, such as R-22, based on tube dimensions and operating conditions.

- High-precision cooling in systems requiring consistent thermal management.

These applications highlight the versatility of capillary tubes in optimizing HVAC performance across various industries.

Advantages of High-Quality Copper Capillary Tubes

Superior Thermal Conductivity for Efficient Heat Transfer

High-quality copper capillary tubes excel in thermal conductivity, making them indispensable for efficient heat transfer in HVAC systems. Copper's thermal conductivity ranges between 300 and 400 W/(m•K), which allows it to transfer heat rapidly and evenly. This property ensures that HVAC systems maintain optimal cooling and heating performance, even under demanding conditions.

An experimental study on ultra-thin flat heat pipes (UTFHPs) demonstrated the exceptional thermal performance of copper-based designs. The study highlighted how innovative composite wick structures, combining copper foam and screen mesh, significantly enhanced heat transfer capacity. These designs improved capillary action and vapor transport, which are critical for maintaining consistent thermal management in HVAC systems.

Copper capillary tubes also feature smooth internal surfaces that reduce flow resistance. This characteristic minimizes energy loss during refrigerant circulation, ensuring that heat exchangers operate at peak efficiency. By facilitating rapid heat dissipation, these tubes contribute to the overall reliability and performance of HVAC systems.

Enhanced Energy Efficiency and Reduced Power Consumption

Copper capillary tubes play a pivotal role in reducing energy consumption in HVAC systems. Their high thermal conductivity ensures efficient heat exchange, which minimizes the workload on compressors and other system components. This efficiency translates into lower power usage and reduced operational costs.

Several factors contribute to the energy-saving capabilities of copper tubes:

- Low flow resistance loss: Copper's smooth internal surface reduces friction, allowing refrigerants to flow more freely. This efficiency enhances the performance of heat exchangers and lowers energy requirements.

- Increased heat exchange area: Internally grooved copper tubes expand the surface area available for heat transfer. This design improves cooling efficiency while reducing pressure drops within the system.

- Consistent thermal performance: Copper's ability to maintain stable thermal conductivity ensures that HVAC systems operate efficiently, even under fluctuating environmental conditions.

These attributes make copper capillary tubes a preferred choice for energy-efficient HVAC solutions. By optimizing refrigerant flow and heat transfer, they help reduce the carbon footprint of residential and commercial buildings.

Durability and Corrosion Resistance for Long-Term Use

Durability is a defining feature of high-quality copper capillary tubes. Copper's natural resistance to corrosion ensures that these tubes maintain their structural integrity over extended periods. This characteristic is particularly important in HVAC systems, where exposure to moisture and varying temperatures can lead to material degradation.

Copper capillary tubes undergo rigorous testing to meet industry standards for durability and performance. Their ability to withstand harsh environments, such as those found in industrial and marine applications, makes them a reliable choice for long-term use. Additionally, copper's malleability allows for easy installation and maintenance, further enhancing its practicality in HVAC systems.

The corrosion-resistant properties of copper also contribute to system longevity. By preventing the buildup of rust and other contaminants, these tubes ensure consistent refrigerant flow and optimal system performance. This reliability reduces the need for frequent replacements, lowering maintenance costs and enhancing the overall value of HVAC installations.

Tip: Investing in high-quality copper capillary tubes, such as those offered by Taojun HVAC, ensures long-lasting performance and energy efficiency. Their superior characteristics make them an excellent choice for both residential and commercial applications.

Compact Design for Space-Saving HVAC Systems

Copper capillary tubes offer a compact design that is ideal for space-saving HVAC systems. Their small diameter and lightweight construction allow engineers to integrate them into tight spaces without compromising performance. This feature is particularly valuable in urban environments, where HVAC systems must fit within limited building footprints.

The compact nature of copper capillary tubes enables manufacturers to design HVAC systems that are both efficient and unobtrusive. These tubes can be arranged in intricate configurations, maximizing the use of available space while maintaining optimal refrigerant flow. Their flexibility supports innovative designs, such as modular systems, which are increasingly popular in residential and commercial applications.

Note: The compact design of copper capillary tubes not only saves space but also reduces material usage, contributing to sustainable building practices.

Benefits of Compact Copper Capillary Tubes in HVAC Systems

- Space Optimization: Copper capillary tubes minimize the physical footprint of HVAC systems, making them suitable for small apartments, offices, and industrial facilities.

- Ease of Installation: Their lightweight and flexible design simplify installation, reducing labor costs and project timelines.

- Enhanced System Efficiency: Despite their small size, these tubes maintain consistent refrigerant flow, ensuring reliable cooling and heating performance.

- Versatility: Copper capillary tubes adapt to various HVAC configurations, including split systems and ductless setups.

Applications in Modern HVAC Systems

Copper capillary tubes are integral to compact HVAC systems used in high-density urban areas. Their ability to fit into confined spaces makes them essential for portable air conditioners, mini-split systems, and rooftop units. In addition, their compact design supports the development of energy-efficient systems that align with green building standards.

Studies have shown that compact copper tubing improves thermal management in HVAC systems. By optimizing refrigerant flow, these tubes enhance the Coefficient of Performance (COP), reducing energy consumption. This efficiency is critical for meeting the growing demand for sustainable cooling solutions.

When considering what type of copper tubing is used for air conditioning and refrigeration, the compact design of copper capillary tubes stands out as a key advantage. Their ability to deliver high performance in a small form factor makes them indispensable for modern HVAC applications.

What Type of Copper Tubing Is Used for Air Conditioning and Refrigeration?

Overview of Copper Tubing Types: Plain Tube vs. Straight Tube

Copper tubing plays a pivotal role in HVAC systems, offering versatility and efficiency for refrigerant flow regulation. Two primary types of copper tubing dominate the industry: Plain Tube and Straight Tube. Each type serves distinct purposes, catering to specific system requirements.

Plain tubes are characterized by their high precision and corrosion resistance. Their smooth internal surfaces reduce flow resistance, ensuring consistent refrigerant circulation. These tubes excel in applications requiring low flow rates, such as residential air conditioning systems. Straight tubes, on the other hand, feature a flat and ripple-free surface, making them ideal for high-precision applications like electronics cooling and aerospace systems.

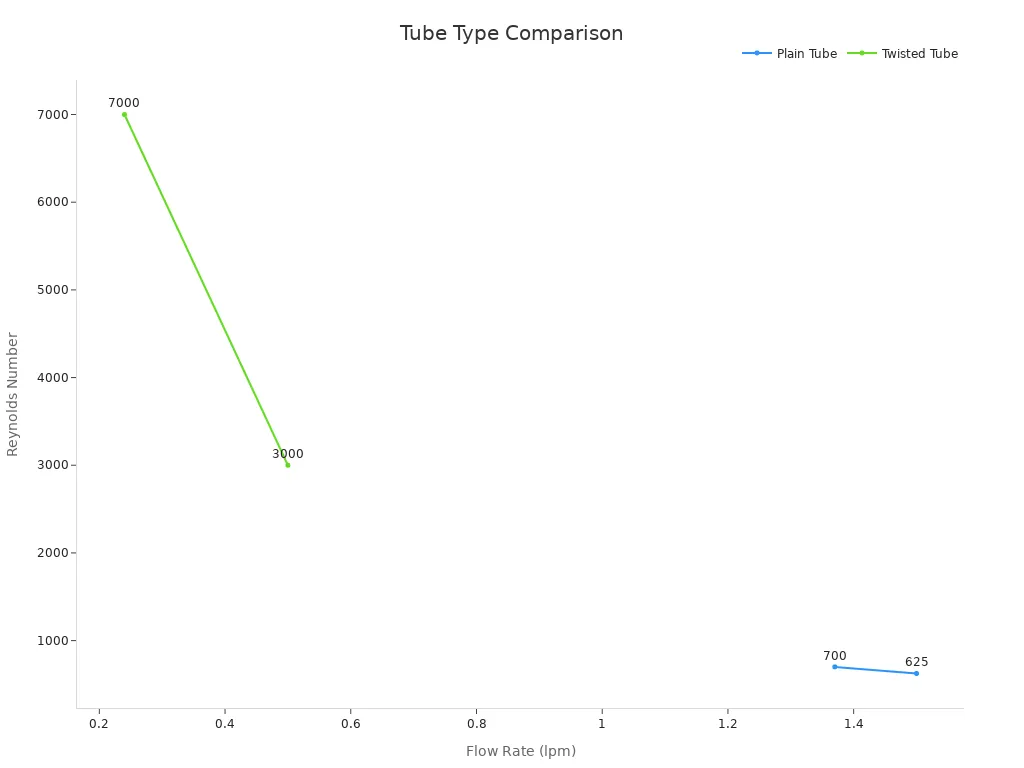

The table below compares the performance of plain and twisted tubes based on flow rate and Reynolds number:

| Tube Type | Flow Rate (lpm) | Reynolds Number | Performance Comparison |

|---|---|---|---|

| Plain Tube | 1.5 | 625 | Better performance at low flow |

| Plain Tube | 1.37 | 700 | Better performance at low flow |

| Twisted Tube | 0.5 | 3000 | Better performance at high flow |

| Twisted Tube | 0.24 | 7000 | Better performance at high flow |

This comparison highlights the importance of selecting the right tubing type based on system requirements. Plain tubes perform optimally at lower flow rates, while twisted tubes excel in high-flow scenarios.

Key Features of Oxygen-Free Copper (OFC) Tubes

Oxygen-Free Copper (OFC) tubes represent the pinnacle of copper tubing technology. These tubes are crafted with copper purity exceeding 99%, ensuring superior performance in HVAC applications. Their high cleanliness and precision make them ideal for systems requiring consistent thermal management.

Key features of OFC tubes include:

- Exceptional Thermal Conductivity: OFC tubes transfer heat efficiently, maintaining stable system temperatures.

- Corrosion Resistance: The absence of oxygen minimizes the risk of oxidation, extending the lifespan of the tubes.

- High Ductility: OFC tubes can be easily shaped and installed, accommodating complex system designs.

These features make OFC tubes indispensable for demanding environments, such as LNG gas applications and shipbuilding. Their ability to withstand harsh conditions ensures reliable performance and long-term durability.

Benefits of High-Purity Copper for HVAC Applications

High-purity copper offers unparalleled advantages for HVAC systems, enhancing both performance and longevity. Its thermal conductivity, approximately 400 times greater than other metals, ensures efficient heat transfer. This property reduces the workload on compressors, improving energy efficiency and lowering operational costs.

Research highlights several benefits of high-purity copper:

- Copper line sets improve HVAC system energy performance by up to 20% compared to less conductive materials.

- Properly installed copper tubing can last up to 50 years, significantly outperforming alternative materials.

- High-purity copper minimizes energy loss during refrigerant circulation, ensuring consistent system operation.

Tip: Investing in high-purity copper tubing, such as Taojun HVAC's Copper Capillary Tubes, guarantees long-term benefits for residential and commercial applications.

These advantages underscore the importance of using high-quality copper in HVAC systems. By optimizing refrigerant flow and enhancing thermal management, high-purity copper ensures reliable and efficient system performance.

Optimizing HVAC Systems with Copper Capillary Tubes

Maintaining Consistent Refrigerant Flow for Cooling Efficiency

Copper capillary tubes ensure consistent refrigerant flow, which is essential for maintaining cooling efficiency in HVAC systems. Their precision-engineered design regulates the refrigerant's pressure and flow rate, ensuring it reaches the evaporator in the correct state. This process prevents issues like evaporator starvation or flooding, which can compromise cooling performance.

The smooth internal surface of copper tubes minimizes flow resistance, allowing refrigerants to circulate efficiently. This characteristic enhances the heat exchange process, ensuring the system operates at peak performance. Additionally, copper's excellent thermal conductivity ensures rapid heat transfer, further optimizing cooling efficiency.

Tip: Regularly inspect copper capillary tubes for blockages or wear to maintain consistent refrigerant flow and avoid system inefficiencies.

Reducing System Strain and Preventing Overheating

Copper capillary tubes play a critical role in reducing strain on HVAC components. By regulating refrigerant flow, these tubes prevent the compressor from overworking, which can lead to overheating and potential system failure. Properly sized and installed copper tubes ensure that the system operates within its designed parameters, minimizing stress on critical components.

The durability and corrosion resistance of copper further contribute to system reliability. These properties prevent material degradation, ensuring that the tubes maintain their structural integrity under varying environmental conditions. This reliability reduces the likelihood of system malfunctions caused by overheating or excessive strain.

Note: Using high-quality copper capillary tubes, such as those from Taojun HVAC, can significantly reduce maintenance costs by preventing overheating-related issues.

Enhancing System Longevity and Reliability

Copper capillary tubes enhance the longevity and reliability of HVAC systems by ensuring consistent performance over time. Their resistance to corrosion and wear allows them to withstand harsh operating conditions, reducing the need for frequent replacements. This durability translates into lower maintenance costs and extended system lifespans.

The precision and high purity of copper used in these tubes also contribute to their reliability. By maintaining consistent refrigerant flow and preventing issues like blockages or leaks, copper capillary tubes ensure that HVAC systems operate efficiently and reliably for years.

Callout: Investing in premium copper capillary tubes is a cost-effective way to enhance the durability and performance of HVAC systems, ensuring long-term operational success.

Selecting and Maintaining Copper Capillary Tubes

Factors to Consider When Choosing Copper Capillary Tubes

Selecting the right copper capillary tubes requires careful evaluation of several critical factors. These include material quality, tube type, and application-specific requirements. High-quality copper ensures optimal thermal conductivity and durability, making it essential for HVAC systems. Industry standards, such as ASTM B280 and B828, provide guidelines for seamless copper tubing and soldering practices, ensuring reliable performance.

| Standard | Description |

|---|---|

| ASTM B280 | Seamless Copper Tube for Air Conditioning and Refrigeration Field Service |

| B32 | Specification for Solder Metal |

| B153 | Test Method for Expansion (Pin Test) of Copper and Copper-Alloy Pipe and Tubing |

| B577 | Test Methods for Detection of Cuprous Oxide (Hydrogen Embrittlement Susceptibility) in Copper |

| B828 | Practice for Making Capillary Joints by Soldering of Copper and Copper Alloy Tube and Fittings |

Market trends also influence tube selection. Straight and coiled tubes cater to different applications, such as HVAC, refrigeration, and medical devices. Factors like regional market share, raw material fluctuations, and application-specific needs play a significant role in determining the most suitable tube type.

Tip: Prioritize copper capillary tubes that meet industry standards and align with your system's operational requirements for maximum efficiency and reliability.

Best Practices for Installation and Maintenance

Proper installation and maintenance of copper capillary tubes ensure long-term system performance. Design and installation protocols emphasize the importance of pressure systems, drainage, and solar energy applications. Joining methods, such as soldering and brazing, create durable connections that withstand high-pressure environments.

- Key Installation Guidelines:

- Use fittings, solders, and fluxes designed for copper tubing to prevent leaks and ensure robust joints.

- Follow manufacturer recommendations for tube sizing and placement to optimize refrigerant flow.

- Inspect connections for uniformity and cleanliness before soldering or brazing.

Routine maintenance involves inspecting tubes for signs of wear, corrosion, or blockages. Cleaning the internal surfaces of the tubes prevents refrigerant flow disruptions, while regular checks on joints ensure system reliability.

Note: Proper installation techniques and consistent maintenance reduce the risk of system failures and extend the lifespan of copper capillary tubes.

Identifying Signs of Wear and When to Replace Tubes

Recognizing wear in copper capillary tubes is crucial for preventing system inefficiencies. Common signs include discoloration, reduced refrigerant flow, and visible corrosion. Blockages caused by debris or moisture can lead to overheating and strain on the compressor.

- Indicators of Tube Wear:

- Decreased cooling efficiency due to restricted refrigerant flow.

- Visible cracks or deformities in the tubing.

- Increased energy consumption resulting from system strain.

Replacing worn tubes promptly prevents further damage to HVAC components. High-quality copper capillary tubes, such as those offered by Taojun HVAC, provide superior durability and corrosion resistance, reducing the frequency of replacements.

Callout: Regular inspections and timely replacements ensure consistent system performance and minimize operational costs.

High-quality copper capillary tubes are indispensable for modern HVAC systems. Their superior thermal conductivity enhances energy efficiency, ensuring optimal heat transfer. Corrosion resistance extends their lifespan, reducing replacement costs and maintenance efforts. Additionally, copper's recyclability aligns with sustainable practices, offering long-term value for environmentally conscious applications.

Callout: Taojun HVAC's premium copper capillary tubes deliver unmatched performance and reliability. Investing in these tubes guarantees efficient, durable, and eco-friendly solutions for residential and commercial HVAC systems.

By optimizing refrigerant flow and minimizing system strain, copper capillary tubes ensure consistent and long-lasting performance, making them a cornerstone of advanced HVAC technology.

FAQ

What makes copper capillary tubes better than other materials for HVAC systems?

Copper capillary tubes excel due to their superior thermal conductivity, corrosion resistance, and durability. These properties ensure efficient heat transfer, long-term reliability, and reduced maintenance costs. Their recyclability also makes them an environmentally friendly choice for HVAC applications.

How do I choose the right size of copper capillary tube for my HVAC system?

Selecting the correct size depends on the system's refrigerant type, operating pressures, and cooling capacity. Consulting manufacturer guidelines or working with an HVAC professional ensures proper sizing, which optimizes refrigerant flow and prevents system inefficiencies.

Can copper capillary tubes be used in extreme environments?

Yes, copper capillary tubes perform well in extreme conditions. Their corrosion resistance and high durability make them suitable for harsh environments, including industrial, marine, and high-temperature applications. Oxygen-Free Copper (OFC) tubes are particularly effective in demanding scenarios.

How often should copper capillary tubes be inspected or replaced?

Regular inspections should occur annually to check for blockages, corrosion, or wear. Replacement depends on the tube's condition and system performance. High-quality tubes, like those from Taojun HVAC, often last decades with proper maintenance.

Are copper capillary tubes compatible with all refrigerants?

Copper capillary tubes are compatible with most refrigerants, including R-22 and R-410A. However, verifying compatibility with the specific refrigerant used in your HVAC system ensures optimal performance and prevents potential issues.