Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

Custom Label Roll Bond Evaporators: Branding Solutions for OEM Partners

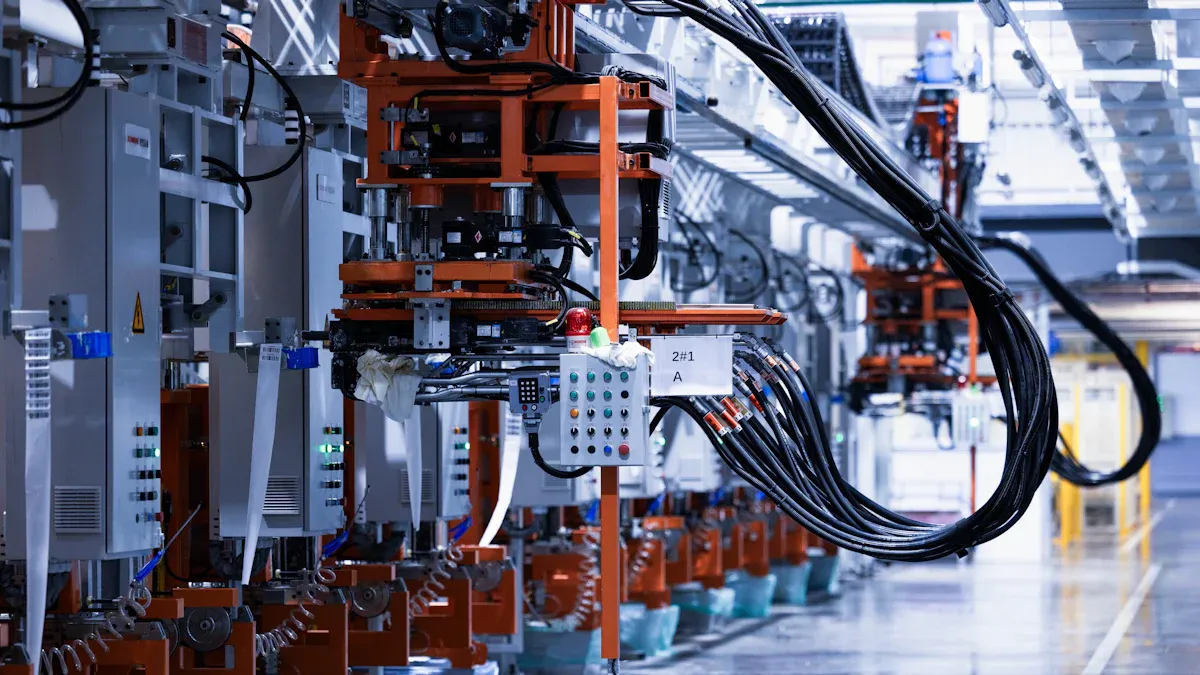

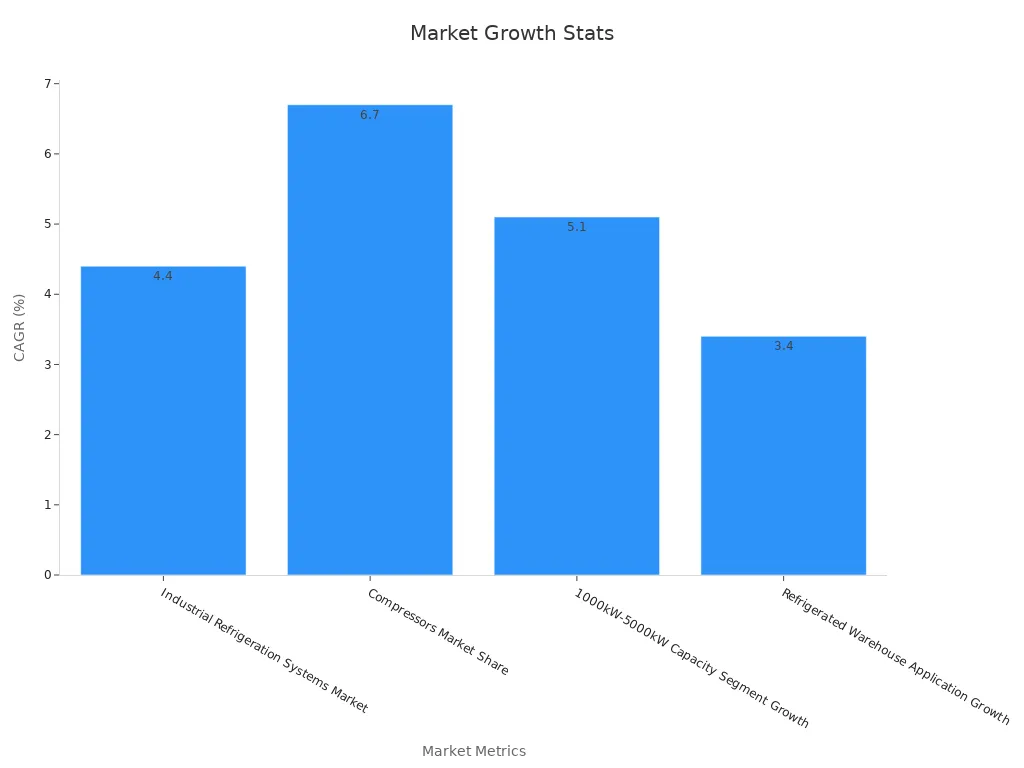

Custom label roll bond evaporators give OEM partners a powerful tool to showcase their brand directly on critical refrigeration components. In a market where industrial refrigeration systems reached $19.73 billion in 2022 and are projected to grow to $29.07 billion by 2031, brand visibility remains vital.

By integrating a Refrigerator Spare Parts Aluminum Roll bonded evaporator with custom branding, companies can communicate reliability and quality at every point of contact. This approach not only sets products apart but also builds lasting trust with end users.

Key Takeaways

- Custom label roll bond evaporators help OEM partners boost brand visibility by placing their logo directly on key refrigeration parts, building trust and recognition.

- These evaporators offer high efficiency, lightweight design, and cost savings, making them ideal for modern refrigeration and energy-saving applications.

- Custom labels create a strong emotional connection with customers, increase product appeal, and encourage repeat purchases through consistent branding.

- Choosing durable materials and smart label placement ensures labels last in tough environments without affecting evaporator performance.

- Integrating custom labeling into OEM production lines improves efficiency, reduces costs, and supports compliance with industry standards.

Refrigerator Spare Parts Aluminum Roll bonded evaporator: Definition and OEM Relevance

What Are Roll Bond Evaporators?

A Refrigerator Spare Parts Aluminum Roll bonded evaporator serves as a critical component in modern refrigeration systems. Manufacturers create these evaporators by bonding two aluminum sheets together through a rolling process, forming internal channels for refrigerant flow. The typical material thickness ranges from 1.5 to 2.8 mm, with finished plates measuring between 1.1 and 2.5 mm. Surface treatments, such as spray coatings, enhance corrosion resistance and durability. The production process involves several precise steps, including material preparation, cleaning, printing, rolling, annealing, inflating, punching, folding, welding, leakage testing, and final inspection.

Roll bond evaporators offer high thermal efficiency and lightweight construction. Their compact design makes them suitable for a wide range of applications, including refrigerators, freezers, and even electric vehicle battery cooling systems. The market for these evaporators reached approximately USD 1.2 billion in 2023 and is projected to grow to USD 2.1 billion by 2032, reflecting a CAGR of 6.2%. This growth highlights the increasing demand for energy-efficient and environmentally friendly refrigeration solutions.

Note: Innovations in roll bond evaporator technology include the integration of smart sensors, optimization of fin spacing, and advanced manufacturing techniques, all aimed at improving performance and reliability.

Importance for OEM Partners

OEM partners benefit significantly from integrating Refrigerator Spare Parts Aluminum Roll bonded evaporator solutions into their product lines. These evaporators deliver superior heat transfer efficiency, lightweight construction, and cost-effectiveness. The table below highlights key technical characteristics:

| Technical Characteristic | Description |

|---|---|

| Construction | Two aluminum sheets rolled to create internal channels |

| Tubing | copper tubes for easy system integration |

| Surface Coating | Plastic powder coating for protection |

| Design Features | Lightweight, compact, cost-effective |

| Heat Transfer Efficiency | Superior to conventional evaporators |

| Types | Single-side (cost-effective), Double-side (enhanced heat transfer) |

| Applications | Refrigerators, freezers, showcases |

| Innovations | Smart sensors, optimized fin spacing, advanced materials |

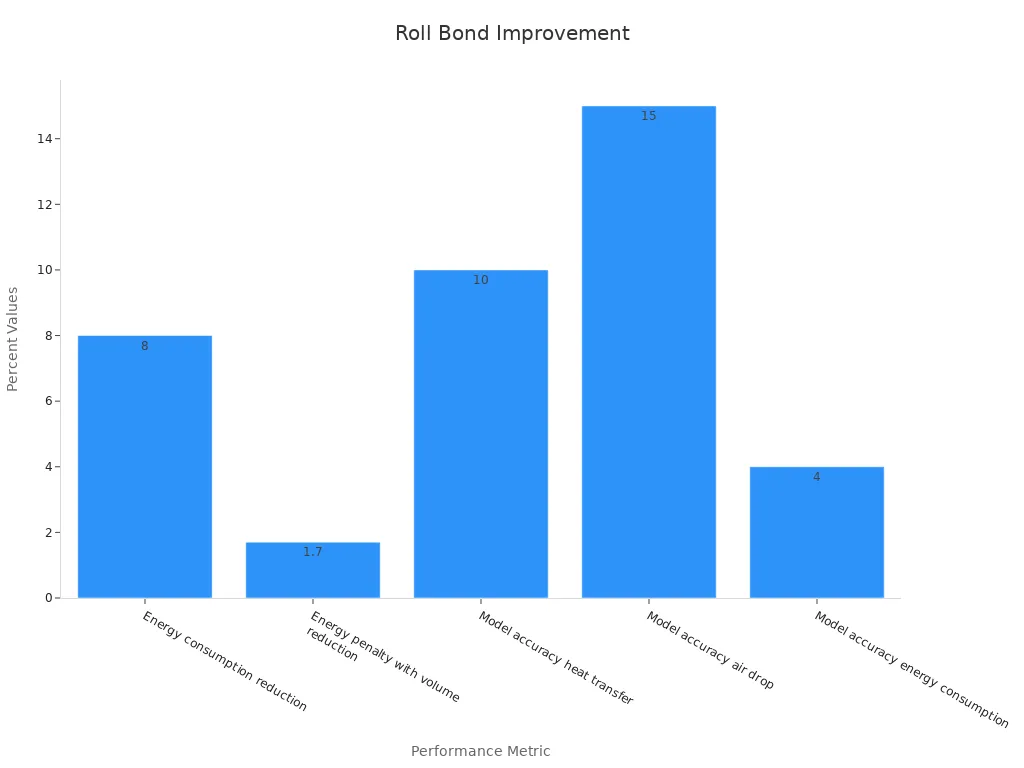

OEMs can expect measurable performance improvements when using Refrigerator Spare Parts Aluminum Roll bonded evaporator technology. For example, these evaporators can reduce energy consumption by up to 8% compared to conventional fin-on-tube designs. Pull-down times decrease significantly, and even with a 50% reduction in evaporator volume, energy consumption increases by only 1.7%. Model predictions for heat transfer and energy use remain highly accurate, ensuring reliable system performance.

OEMs gain a competitive edge by adopting these advanced evaporators, meeting market demands for efficiency, sustainability, and innovation.

Branding Benefits for OEM Partners

Enhanced Brand Recognition

Custom label roll bond evaporators allow OEM partners to display their brand identity directly on essential refrigeration components. This approach ensures that every product leaving the factory carries a consistent and recognizable corporate image. When customers see a familiar logo or design, they associate it with reliability and quality.

- OEM partners can offer a complete, integrated package that features their branding.

- Products with custom labels create heightened market awareness for the partner company.

- Custom branding enables partners to quote private label products, increasing their presence against main brands.

- Private label products foster customer loyalty, as buyers return to the same OEM for replacements or upgrades.

- Products produced by highly accredited manufacturers reinforce the brand’s reputation for quality and compliance.

Consistent branding across all components strengthens the visual identity of the OEM partner, making their products stand out in a crowded marketplace.

Competitive Differentiation

In a competitive market, differentiation is key. Custom labels on roll bond evaporators provide OEM partners with unique opportunities to set their products apart. Labels can feature distinct colors, typography, and graphics that align with the brand’s identity. Clear messaging on labels communicates unique product features and benefits, while authenticity claims—such as eco-friendly or energy-efficient—appeal to specific consumer segments.

- Labels enhance visual appeal and reinforce brand values.

- Storytelling through labels creates emotional connections with customers.

- Customization options allow OEMs to tailor products to meet customer preferences.

- Exceptional customer service and brand values communicated through labels further differentiate products.

A study found that 68% of consumers are willing to pay more for products labeled as cruelty-free. This statistic demonstrates that labels conveying ethical or quality information can significantly influence purchasing decisions. Custom labels not only attract attention but also encourage customers to choose one brand over another.

| Competitive Performance Metric | Explanation | Benefit from Custom Labels |

|---|---|---|

| Brand Loyalty | Builds consumer trust through consistent quality | Increases repeat purchases and customer retention |

| Profit Margins | Lower production costs via economies of scale | Enables competitive pricing and higher profitability |

| Market Share Growth | Attracts and retains customers through unique branding | Differentiates products in crowded markets |

| Customer Satisfaction | Enhanced by visual appeal and clear messaging | Improves willingness to pay premium prices |

| Emotional Connection | Storytelling and authenticity in labels | Strengthens brand affinity and loyalty |

Customer Trust and Perceived Value

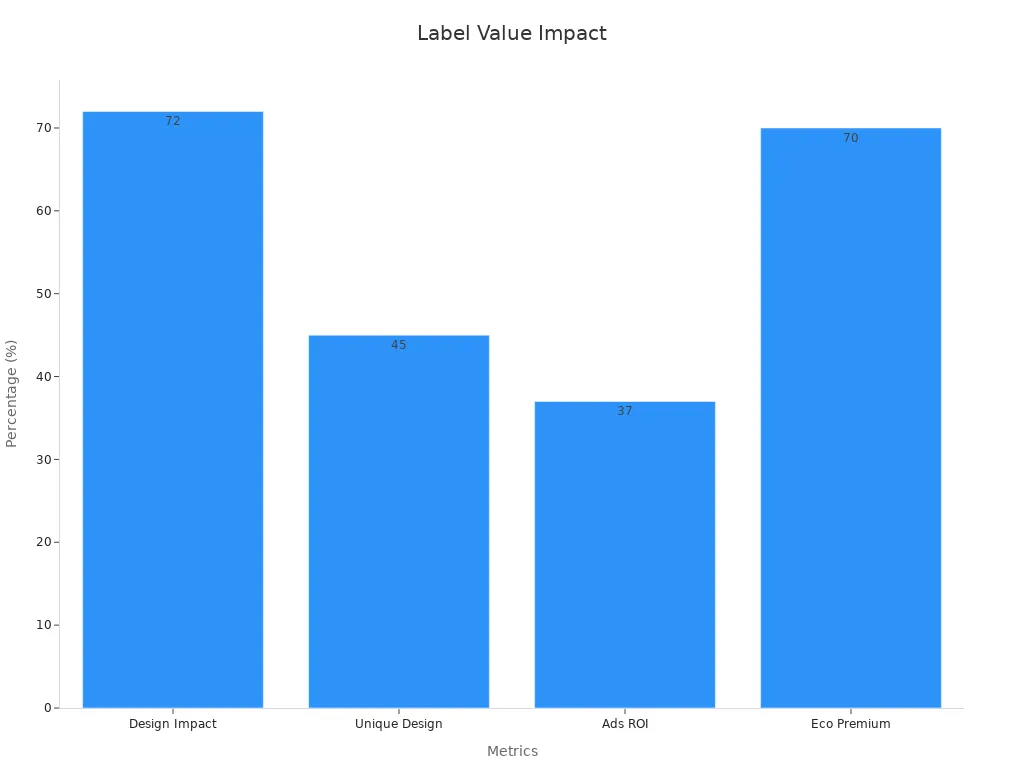

Custom labeling plays a crucial role in building customer trust and enhancing perceived product value. When customers encounter a product with a well-designed, informative label, they perceive it as higher quality and more trustworthy. Packaging design, including custom labels, influences buying decisions for 72% of shoppers. Unique packaging designs increase customer interest by 45%, while ads with custom labels achieve a 37% higher return on investment. Furthermore, 70% of customers express willingness to pay more for sustainable packaging, highlighting the impact of eco-friendly custom labels.

| Statistic | Impact on Perceived Product Value |

|---|---|

| 72% of shoppers say packaging design affects their buying choices | Indicates packaging design, including custom labels, influences consumer decisions |

| Unique packaging designs increase customer interest by 45% | Shows custom labeling attracts more consumer attention |

| Ads with custom labels achieve 37% higher return on investment | Demonstrates marketing effectiveness of custom labels |

| 70% of customers willing to pay more for sustainable packaging | Highlights willingness to pay premium linked to eco-friendly custom labels |

Custom label roll bond evaporators help OEM partners build trust, increase perceived value, and drive customer loyalty. These branding solutions position OEMs for long-term success in a rapidly evolving market.

Customization Options and Process

Label Design and Placement

Effective label design and strategic placement play a crucial role in enhancing the visual appeal and market performance of roll bond evaporators. Companies that invest in aesthetic design often see measurable business benefits. The table below summarizes key findings from industry research:

| Evidence Type | Description | Quantitative Findings | Example |

|---|---|---|---|

| Earnings Impact | Firms with strong design focus outperform peers | 32% higher earnings for 93 firms across 9 product categories | Hertenstein et al. (2005) |

| Consumer Influence | Aesthetics drive purchase decisions | Up to 60% of automotive purchases explained by aesthetics | Kreuzbauer and Malter (2005) |

| Market Performance | Design changes boost market share and pricing | 30% MSRP increase, 54% market share gain in case studies | Pauwels et al. (2004), Blonigen et al. |

| Eye-Tracking Metrics | Visual attention linked to label design | Longer fixations and dwell time for high-aesthetic products | Khalighy et al., Luo et al. |

| Visual Congruence | Label-product harmony enhances perception | Improved consumer perception with congruent shapes | Westerman et al. |

Designers use eye-tracking technology to measure how labels attract and hold consumer attention. Products with visually appealing labels receive longer fixations, indicating higher engagement and preference. Placement on the evaporator should maximize visibility without interfering with function. Labels positioned on flat, accessible surfaces ensure easy identification during installation and maintenance.

Material and Printing Choices

Selecting the right materials and printing methods ensures label durability and legibility in demanding environments. Manufacturers often choose vinyl or polyester substrates for their resistance to chemicals, moisture, and UV exposure. Vinyl labels resist fading and peeling, while polyester offers superior tear and chemical resistance. Permanent adhesives secure labels to aluminum surfaces, preventing tampering or accidental removal.

Printing methods such as digital, flexographic, and thermal transfer are matched to the chosen substrate. Protective laminates, typically 1 to 3 mil polycarbonate, shield labels from abrasion and harsh conditions. Compliance with standards like UL 969 and ISO9001:2015 guarantees that labels meet industry requirements for quality and longevity. Specialized labels, including safety and warning types, undergo rigorous testing to ensure performance in extreme temperatures and environments.

Integration with OEM Production

Seamless integration of custom labels into OEM production lines enhances efficiency and consistency. Manufacturers use configurable labeling systems and prebuilt templates to streamline setup. Annotation teams can adjust user interfaces and workflows to match project needs, reducing reliance on technical staff. Hotkeys and automation features, such as AI-assisted pre-labeling, speed up the labeling process and minimize manual effort.

Real-time collaboration and quality control workflows maintain high standards throughout production. Agile, iterative approaches—using smaller batches and frequent feedback—improve supervision and accuracy. API and SDK connectivity allow for direct integration with OEM data systems, supporting automation and scalability. Case studies show that these process improvements can boost labeling speed and efficiency by 30–40%, ensuring timely delivery and consistent branding across all products.

Key Considerations for OEMs

Quality Assurance

OEMs must prioritize quality assurance when selecting custom label solutions for refrigeration components. Reliable quality control ensures that each Refrigerator Spare Parts Aluminum Roll bonded evaporator meets strict performance and durability standards. Manufacturers often implement multi-stage inspections, including visual checks, leak testing, and functional assessments. Laser marking technology provides a robust method for labeling, offering corrosion resistance and long-lasting identification. This method supports traceability by enabling barcodes, QR codes, and unique identifiers on each component. These features simplify audits and help maintain consistent quality across production batches. Manufacturers also use advanced testing equipment to verify that labels remain legible and intact under harsh operating conditions.

Compliance and Standards

Adhering to industry regulations is essential for OEMs producing custom labeled refrigeration components. The following table summarizes key compliance standards and benchmarks:

| Aspect | Details |

|---|---|

| Compliance Standard | Energy Conservation Program under EPCA (42 U.S.C. 6291-6317), regulated by U.S. DOE |

| Equipment Definition | Commercial refrigerators, freezers, or refrigerator-freezers as per 10 CFR 431.62 and EPCA definitions |

| Equipment Classes | Families: VOP, SVO, HZO, VCT, HCT, VCS, HCS, SOC, CB, PD |

| Condensing Unit Configurations | RC (Remote Condensing), SC (Self Contained) |

| Operating Temperatures | H (High), M (Medium), L (Low), I (Ice Cream) |

| Statistical Benchmarks | Efficiency distributions based on DOE test data, manufacturer submissions, ENERGY STAR data, DOE CCD |

| Compliance Certification | DOE Compliance Certification Database (CCD) for refrigeration equipment |

Manufacturers must ensure that each Refrigerator Spare Parts Aluminum Roll bonded evaporator complies with these standards. Proper labeling supports regulatory requirements and provides clear identification for audits and certifications.

Cost and Lead Time

Cost and lead time play a significant role in OEM decision-making. Custom labeling may introduce additional expenses, but efficient production processes help control costs. Laser marking allows for rapid customization, reducing setup time and minimizing waste. OEMs benefit from streamlined workflows that integrate labeling into existing assembly lines. Shorter lead times enable faster delivery to market, supporting customer demands and seasonal fluctuations. By working with experienced suppliers, OEMs can balance quality, compliance, and cost-effectiveness when sourcing Refrigerator Spare Parts Aluminum Roll bonded evaporator solutions.

Tip: Early collaboration with suppliers helps optimize design, material selection, and labeling methods, resulting in better cost control and timely project completion.

Success Stories and Use Cases

Real-World OEM Examples

Leading OEMs in the refrigeration industry have adopted custom label roll bond evaporators to strengthen their market presence. For instance, global appliance manufacturers such as Haier and Whirlpool have integrated branded evaporators into their product lines. These companies report increased customer recognition and loyalty after implementing visible branding on internal components. Their approach ensures that every unit, even after years of use, continues to reinforce the brand’s reputation for quality and reliability.

Industrial sectors outside refrigeration also demonstrate the value of tailored OEM solutions. In the aviation industry, StorkJet developed tail-specific performance models for aircraft fuel consumption. These models, based on real operational data, provide more accurate estimations than standard OEM models. By adjusting recommendations for each aircraft, StorkJet uncovers cost savings and improves operational efficiency. This example highlights how OEMs can leverage data-driven customization to deliver superior value and differentiate their offerings.

Measurable Branding Outcomes

Custom label solutions deliver quantifiable improvements for OEM partners. Companies that invest in branded components often see significant gains in operational efficiency and customer satisfaction. The following results illustrate the impact of advanced OEM strategies:

- A 75% reduction in customer delinquency over 120 days late, resulting in $450 million in improved cash flow.

- A 10% decrease in machine downtime through predictive maintenance and vibration analysis.

- Enhanced preventive maintenance and remote troubleshooting, which lower total cost of ownership.

- Improved asset utilization, maximizing return on investment and reducing unnecessary equipment rentals.

- Equipment operator tracking that reduces maintenance costs and increases safety by identifying training needs.

These outcomes show that custom label roll bond evaporators not only elevate brand visibility but also drive measurable business results. OEMs who embrace these solutions position themselves for long-term growth and industry leadership.

Custom label roll bond evaporators give OEM partners a practical way to boost brand visibility and stand out in a competitive market. The North America industrial evaporators market, valued at $4.5 billion in 2024, is projected to reach $6.3 billion by 2033, driven by demand for energy-efficient and innovative solutions. Custom labeling not only increases market recognition but also strengthens customer loyalty, as shown by rising brand equity scores and repeat purchase rates.

| Metric | Benchmark/Result | Impact |

|---|---|---|

| Social Media Reach | 150K+ impressions/month | Higher brand recall |

| Branded Keyword Search Volume | 20% YoY increase | Growing market interest |

| Brand Equity Score | 75%+ favorable responses | Strong customer satisfaction |

OEMs who invest in custom labeling position their brands for long-term growth and sustained market leadership.

FAQ

What is a custom label roll bond evaporator?

A custom label roll bond evaporator features a brand’s logo or information printed directly on the component. This approach helps OEM partners reinforce their brand identity and ensures consistent recognition throughout the product’s lifecycle.

How durable are the custom labels on evaporators?

Manufacturers use high-quality materials and advanced printing methods. Labels resist chemicals, moisture, and UV exposure. They remain legible and intact even in demanding refrigeration environments.

Can OEMs choose the design and placement of labels?

Yes. OEM partners select label designs, colors, and placement. Manufacturers offer flexible options to match branding requirements and ensure optimal visibility without affecting performance.

Do custom label evaporators meet industry compliance standards?

Manufacturers ensure all custom label roll bond evaporators comply with international standards such as ISO9001 and UL. Labels also meet regulatory requirements for durability, traceability, and safety.

How do custom labels integrate with existing OEM production lines?

Manufacturers provide configurable labeling systems. These systems streamline integration with OEM assembly lines, reduce manual effort, and maintain consistent branding across all products.