Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

Compact Wire Tube Condenser Integration for Beverage Coolers and Wine Cabinets

Compact Wire Tube Condenser Integration for Beverage Coolers and Wine Cabinets transforms the way these appliances operate. This advanced system increases cooling efficiency, making sure drinks stay at the perfect temperature. Its compact structure saves valuable space, allowing for sleeker designs in both home and commercial settings. Many users notice lower energy bills as a result of improved performance. These advantages support reliable operation and meet the needs of busy households and businesses.

Key Takeaways

- Compact wire tube condensers boost cooling efficiency by increasing heat transfer, keeping beverages perfectly chilled while saving energy.

- Their slim, coiled design saves space, allowing for sleek beverage coolers and wine cabinets without sacrificing performance.

- These condensers reduce energy use and lower operating costs, making them a smart, cost-effective choice for homes and businesses.

- They maintain stable temperatures and operate quietly, protecting beverage quality and creating a comfortable environment.

- Easy to inspect and clean, compact wire tube condensers simplify maintenance and extend the lifespan of cooling appliances.

Compact Wire Tube Condenser Integration for Beverage Coolers and Wine Cabinets: How It Works

Structure and Function of Wire Tube Condensers

Wire tube condensers use a network of metal tubes arranged in a compact, coiled pattern. Manufacturers design these tubes to maximize surface area, which allows for efficient heat transfer from the refrigerant inside the tubes to the surrounding air. The metal, often copper or aluminum, conducts heat quickly. Fins or bends in the tubing further increase the contact area with air, speeding up the cooling process. This structure supports a slim profile, making it ideal for modern beverage coolers and wine cabinets where space is at a premium.

The condenser’s function centers on removing heat from the refrigerant. As the refrigerant passes through the tubes, it releases heat absorbed from inside the cooler or cabinet. The heat then dissipates into the environment, allowing the refrigerant to cycle back and absorb more heat. This continuous process keeps beverages at the desired temperature.

Role in Refrigeration Systems

Wire tube condensers play a critical role in the overall performance of refrigeration systems. Their geometry and material selection directly impact how efficiently the system removes heat. Market studies show that the adoption of wire tube condensers continues to rise in both residential and commercial cooling systems. This trend reflects their superior heat transfer capabilities and energy efficiency.

Experimental research highlights that improvements in condenser geometry can boost the coefficient of performance by 13% to 29%. Sub-cooling increases by up to 24%, which means the system can maintain lower temperatures with less energy. These enhancements result from changes in refrigerant flow and pressure within the condenser, leading to better heat transfer. Compact Wire Tube Condenser Integration for Beverage Coolers and Wine Cabinets ensures reliable cooling, energy savings, and consistent performance for users.

Compact Wire Tube Condenser Integration for Beverage Coolers and Wine Cabinets: Key Advantages

Improved Cooling Efficiency

Compact Wire Tube Condenser Integration for Beverage Coolers and Wine Cabinets delivers a significant boost in cooling efficiency. The advanced design maximizes heat transfer by increasing the surface area exposed to air, which accelerates the removal of heat from the refrigerant. Researchers at MIT have shown that innovative approaches, such as applying an electric field to wire mesh tubes, can nearly double heat transfer efficiency by preventing water droplet accumulation. This method keeps condenser surfaces clear, allowing for uninterrupted cooling performance.

Optimizing the geometry of wire tube condensers also plays a crucial role. Adjustments in wire diameter, spacing, and tube arrangement can enhance the heat transfer coefficient by up to 15%. These improvements translate into measurable gains in system performance. The following table highlights key metrics that quantify the efficiency gains:

| Metric | Classical Condenser | Microchannel Condenser | Improvement / Change |

|---|---|---|---|

| Coefficient of Performance (COP) | 2.086 | 2.351 | Increase by ~12.7% |

| Exergy Efficiency | 23.950% | 25.564% | Increase by ~1.6 percentage points |

| CO2 Emissions (kg/h) | 16.357 | 14.438 | Reduction by ~11.7% |

Note: Enhanced cooling efficiency not only improves beverage preservation but also supports environmental sustainability by reducing emissions.

Space-Saving and Sleek Design

Manufacturers design compact wire tube condensers with a focus on minimal footprint and maximum utility. The coiled tube arrangement allows for a slim profile, making it possible to integrate these condensers into tight spaces within beverage coolers and wine cabinets. This design flexibility enables appliance makers to create products that fit seamlessly into modern kitchens, bars, and commercial environments.

A compact condenser does not compromise on performance. Instead, it increases condenser capacity by up to 20% within the same footprint. The following table summarizes the impact of this design:

| Metric | Improvement Range | Description |

|---|---|---|

| Capacity Increase | 20% | More cooling power in the same space |

| Condensing Temperature Drop | 2 °C | Lower operating temperatures |

| Heat Rejection Rate Increase | 26% | Faster removal of heat from the system |

This space-saving approach results in sleeker appliances that offer both aesthetic appeal and practical benefits. Users enjoy more storage capacity for beverages without sacrificing valuable kitchen or bar space.

Energy Savings and Cost Effectiveness

Energy efficiency stands as a core advantage of compact wire tube condenser integration. By reducing the workload on the compressor and improving heat rejection, these condensers lower overall energy consumption. Studies show that systems with optimized condenser designs can decrease compressor work by up to 11.3%, leading to a corresponding drop in power usage.

The financial benefits become clear when examining operational costs. In cities like Daejeon and Busan, integrated condenser designs have reduced peak energy loads by 11% and average costs by 16%. The table below illustrates these savings:

| Metric | Value | Description |

|---|---|---|

| Peak Load Reduction | 11% | Lower maximum energy consumption |

| Average Cost Reduction | 16% | Decreased operational expenses |

💡 Tip: Choosing appliances with compact wire tube condensers can lead to noticeable savings on monthly energy bills, making them a smart investment for both homes and businesses.

Temperature Stability and Quiet Operation

Temperature stability stands as a critical factor in beverage coolers and wine cabinets. Compact Wire Tube Condenser Integration for Beverage Coolers and Wine Cabinets supports precise temperature regulation by enhancing system efficiency and control. Experimental studies on domestic refrigerators with compact mini-channel flat tube condensers involved continuous temperature monitoring inside both fresh food and freezer compartments. Researchers evaluated performance metrics such as the coefficient of performance (COP) and second-law efficiency under different refrigerant charges and capillary tube lengths. They found that optimal refrigerant charge levels, typically between 48 and 56 grams, and specific tube lengths, such as 2800 millimeters, resulted in the highest system performance and efficiency. These findings indicate that compact condenser integration helps maintain consistent internal temperatures, which is essential for preserving beverage quality and wine integrity.

Advanced control systems further contribute to temperature stability. For example, SCHO-optimized FOPID controllers in Steam Condenser systems achieve rapid stabilization, withsettling times as short as 17.66 seconds and minimal overshoot of 6.06%. These metrics reflect the system's ability to quickly reach and maintain the desired temperature, reducing fluctuations that could compromise stored beverages. The lowest ITAE value of 14.8078 demonstrates minimized cumulative error, ensuring long-term temperature equilibrium.

Quiet operation is another hallmark of modern integrated condenser systems. Manufacturers measure HVAC noise levels in decibels (dB), with lower values indicating quieter performance. Many quiet HVAC units operate between 50 and 60 dB, while advanced mini-split systems can achieve indoor noise levels as low as 20 to 35 dB. For context, a noise level of 25 dB resembles a whisper or a quiet library, making these systems ideal for home and hospitality environments. Features such as heavy-duty compressor blankets, sound insulation, and variable-speed compressors further reduce operational sound. Proper placement and professional installation also play a role in minimizing noise. These design choices ensure that beverage coolers and wine cabinets equipped with compact wire tube condensers operate discreetly, supporting a comfortable and undisturbed environment.

- Typical noise levels for integrated condenser systems:

- Quiet HVAC units: 50–60 dB

- Mini-split systems: 20–35 dB

- Traditional HVAC: 50–75 dB

🛑 Note: Reduced noise and stable temperatures protect beverage flavor and quality, while also enhancing user comfort in both residential and commercial spaces.

Ease of Maintenance

Ease of maintenance remains a top priority for appliance owners and service professionals. Compact wire tube condenser designs simplify routine care and troubleshooting. The open structure of the wire tube arrangement allows for straightforward visual inspection. Technicians can quickly identify dust buildup or obstructions, which helps prevent performance issues before they escalate.

Cleaning the condenser requires minimal effort. Owners can use a soft brush or vacuum to remove dust and debris from the exposed tubes. This process takes only a few minutes and does not require specialized tools. The accessible design also reduces the risk of accidental damage during maintenance, which extends the lifespan of the appliance.

Manufacturers often incorporate features that further streamline maintenance. Removable panels, easy-access mounting, and clear labeling of components support efficient service. These enhancements reduce downtime and ensure that beverage coolers and wine cabinets remain in optimal working condition. Regular maintenance not only preserves energy efficiency but also safeguards the quality of stored beverages.

- Key maintenance benefits:

- Quick visual inspection

- Simple cleaning process

- Reduced risk of damage

- Extended appliance lifespan

💡 Tip: Schedule regular cleaning and inspection to maximize the performance and longevity of your beverage cooler or wine cabinet.

Compact Wire Tube Condenser Integration for Beverage Coolers and Wine Cabinets: What to Consider

Compatibility with Appliance Design

Manufacturers must ensure that wire tube condensers align with the overall appliance design. The condenser’s size, shape, and mounting method should fit seamlessly within the cabinet or cooler. Engineers often collaborate with product designers to select condensers that match the appliance’s airflow patterns and internal layout. This approach maximizes cooling performance and maintains a sleek appearance. Appliance compatibility also extends to electrical connections and refrigerant types. Selecting a condenser that integrates smoothly with existing systems reduces installation time and supports long-term reliability.

Energy Efficiency Ratings and Certifications

Energy efficiency remains a top priority for both commercial and residential users. Industry standards and certifications provide a reliable benchmark for evaluating system performance. Several globally recognized certifications and standards guide manufacturers and buyers:

- LEED Certification: Over 1,515 data centers worldwide have achieved this rating, which includes credits for optimizing energy performance.

- BREEAM Certification: Measures holistic sustainability and ensures energy efficiency goals are met.

- ASHRAE 90.4: Offers technical guidance to minimize life cycle costs and maximize energy efficiency.

- ISO 5001: Provides a framework for improving organizational energy use.

- DIN EN50600: Assesses risk and requirements to define optimal energy strategies.

These certifications use structured, data-driven frameworks to demonstrate the link between energy efficiency ratings and system optimization. Analytical models, such as those combining Data Envelopment Analysis and Principal Component Analysis, further validate the impact of environmental regulations and energy consumption on performance.

Maintenance and Cleaning Requirements

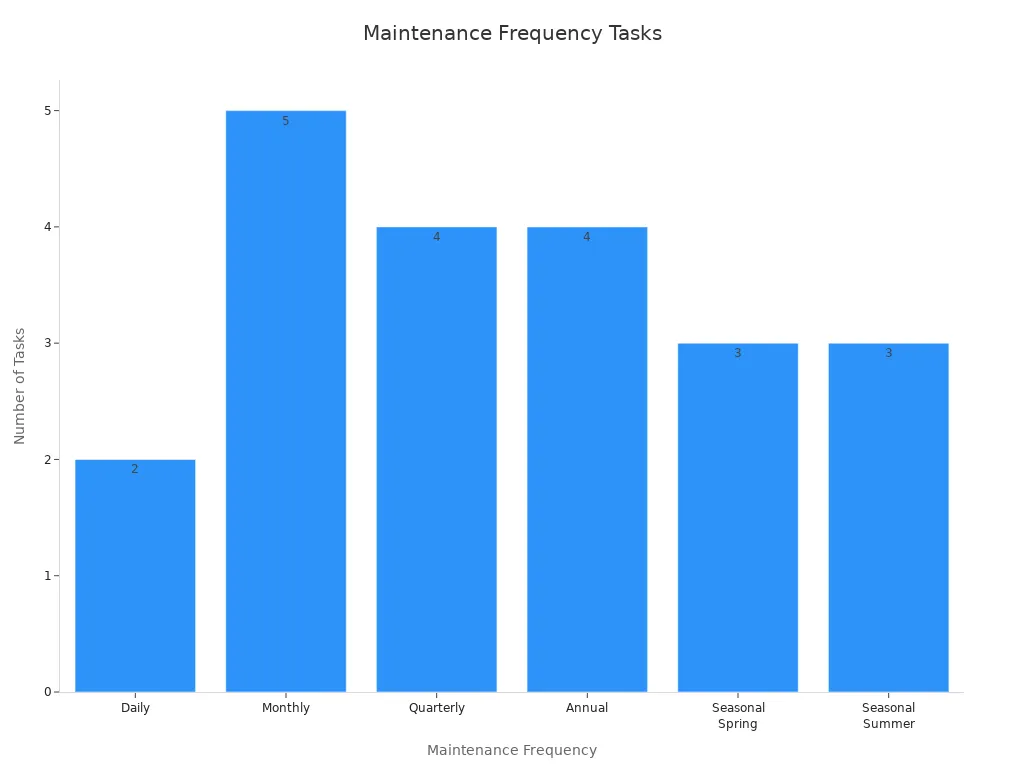

Routine maintenance ensures that integrated condenser systems operate efficiently and last longer. Preventive care includes regular cleaning, inspections, and tune-ups. Neglecting these tasks can lead to reduced efficiency, higher costs, and potential equipment failure. Key maintenance activities focus on components such as condenser coils, filters, and electrical connections. The following table outlines recommended maintenance frequencies and tasks:

| Maintenance Frequency | Key Tasks for Integrated Condenser Systems |

|---|---|

| Daily | Monitor system performance, check for obvious issues |

| Monthly | Replace/clean air filters, inspect belts and pulleys, clean drain pans and condensate lines, test electrical connections, monitor refrigerant levels |

| Quarterly | Thorough cleaning of condenser and evaporator coils, inspect all heating and cooling components, test electrical connections and safety controls, check refrigerant levels and pressure |

| Annual | Full system performance evaluation, deep cleaning of all components including ductwork, calibrate controls and Thermostats, inspect electrical components and safety systems |

| Seasonal (Spring) | Clean condenser coils, check refrigerant levels, clear debris from outdoor units |

| Seasonal (Summer) | Monitor cooling system performance, clean condenser coils as needed, check refrigerant pressure |

A comprehensive maintenance checklist helps ensure no critical tasks are missed. Seasonal plans prepare systems for peak performance and adapt to specific usage conditions, supporting reliability and efficiency.

Selecting the Right Refrigerant

Selecting the right refrigerant plays a crucial role in the performance and sustainability of beverage coolers and wine cabinets. Refrigerants transfer heat efficiently, ensuring that the cooling system maintains optimal temperatures. The choice of refrigerant affects energy consumption, environmental impact, and system compatibility.

Manufacturers often consider several factors when choosing a refrigerant:

- Environmental Impact: Many companies now prefer refrigerants with low Global Warming Potential (GWP) and zero Ozone Depletion Potential (ODP). Hydrocarbon-based refrigerants, such as R600a (isobutane) and R290 (propane), have gained popularity due to their eco-friendly properties.

- Energy Efficiency: Refrigerants with high thermodynamic efficiency help reduce energy usage. This leads to lower operating costs and supports sustainability goals.

- System Compatibility: The refrigerant must match the design and materials of the condenser, compressor, and other system components. Using an incompatible refrigerant can reduce performance or cause damage.

- Safety: Some refrigerants are flammable or toxic. Manufacturers must follow safety standards and regulations to ensure safe operation.

The table below compares common refrigerants used in beverage coolers and wine cabinets:

| Refrigerant | GWP | ODP | Efficiency | Safety Level |

|---|---|---|---|---|

| R134a | 1430 | 0 | High | A1 (Safe) |

| R600a | 3 | 0 | Very High | A3 (Flammable) |

| R290 | 3 | 0 | Very High | A3 (Flammable) |

| R404A | 3922 | 0 | High | A1 (Safe) |

💡 Tip: Always check local regulations and manufacturer recommendations before selecting a refrigerant. Proper selection ensures efficient operation and compliance with environmental standards.

Choosing the right refrigerant supports long-term reliability and efficiency. It also aligns with global efforts to reduce environmental impact.

Compact Wire Tube Condenser Integration for Beverage Coolers and Wine Cabinets: Maximizing Performance

Best Installation Practices

Proper installation sets the foundation for reliable performance. Technicians should position the condenser to allow unrestricted airflow around the coils. They must secure all electrical connections and ensure the refrigerant lines remain free from kinks or sharp bends. Using manufacturer-recommended mounting brackets and hardware prevents vibration and noise. Installers should check that the appliance sits level, which helps refrigerant flow and reduces compressor strain. Following these steps ensures the system operates efficiently from the start.

Routine Cleaning and Maintenance

Regular maintenance keeps cooling systems running at peak efficiency. Owners and service professionals should follow a structured schedule for cleaning and inspection. The table below outlines essential activities and their impact:

| Maintenance Activity | Description & Schedule | Notes / Impact on Performance |

|---|---|---|

| Water Treatment | Control scale, biological growth, and corrosion in open cooling sources. | Prevents fouling and excess energy use. |

| Refrigerant Charge Maintenance | Maintain proper refrigerant levels; check for leaks. | Ensures compressor efficiency and reduces load. |

| Motor & Electrical Components | Clean vents, check seals, maintain wiring and insulation. | Prevents failures and maintains efficiency. |

| Lubrication | Test compressor lubricant annually for contaminants. | Supports compressor longevity. |

| Condenser Tube Cleaning | Use rod & brush, chemical, or tube cleaning guns as needed. | Clean tubes improve heat transfer and efficiency. |

| Cleaning Frequency | Daily logs, periodic reviews, annual lubricant testing, scheduled cleaning outages. | Regular care prevents performance loss. |

Some systems use automatic brush tube cleaning, which keeps tubes clear without stopping operation. This method, combined with routine checks, helps maintain optimal heat exchange and energy savings.

Monitoring for Optimal Operation

Continuous monitoring ensures the system maintains ideal conditions for beverages and wine. Smart monitoring systems track parameters such as ambient temperature, condenser temperature, compressor health, and cabinet temperature. The table below highlights key features:

| Monitoring System | Key Monitored Parameters and Features |

|---|---|

| Smart Draft System | Ambient air temperature, compressor temperature, glycol bath temperature, condenser temperature, cabinet temperature, equipment health, preventive alerts, troubleshooting data |

| Smart Cooler™ | Real-time ambient temperature, condenser temperature |

| Smart Refrigerator™ | Cabinet temperature, compressor health, tap tower temperature, ambient temperature |

| Smart Kegerator™ | Real-time keg levels, temperature, pressure, line cleanliness, equipment health, preventive alerts |

These systems use Wi-Fi or Ethernet for remote access and real-time alerts. They help users respond quickly to any issues, ensuring that Compact Wire Tube Condenser Integration for Beverage Coolers and Wine Cabinets delivers consistent performance and product quality.

Compact Wire Tube Condenser Integration for Beverage Coolers and Wine Cabinets offers clear advantages for both home and commercial users. Users benefit from improved energy efficiency, reduced maintenance costs, and reliable performance. Market research highlights that advanced materials and smart diagnostics extend system lifespan and lower operational expenses. Case studies show that these condensers can cut energy use by up to 19% while supporting compact, modern appliance designs.

For buyers, selecting a system that matches appliance requirements and prioritizes easy maintenance ensures long-term value and consistent cooling.

- Choose models with proven reliability and energy-saving features.

- Look for systems that use corrosion-resistant materials and support smart monitoring.

FAQ

What is a compact wire tube condenser?

A compact wire tube condenser uses coiled metal tubes to transfer heat efficiently. Manufacturers design these condensers for small spaces in beverage coolers and wine cabinets. This technology supports faster cooling and saves space.

How does a wire tube condenser improve energy efficiency?

Wire tube condensers increase surface area for heat transfer. This design reduces compressor workload and lowers energy consumption. Users often see reduced electricity bills.

Are compact wire tube condensers easy to maintain?

Yes. The open tube structure allows for quick visual inspection and easy cleaning. Owners can use a soft brush or vacuum to remove dust.

Regular maintenance helps extend appliance lifespan.

Can these condensers operate quietly?

Manufacturers engineer compact wire tube condensers for quiet operation. Many systems run at noise levels as low as 20–35 dB.

Quiet performance makes them suitable for homes, restaurants, and offices.

What should buyers consider before choosing a condenser?

Buyers should check compatibility with appliance design, energy efficiency ratings, and refrigerant type.

| Factor | Why It Matters |

|---|---|

| Compatibility | Ensures proper fit |

| Efficiency Rating | Reduces energy costs |

| Refrigerant | Supports sustainability |