Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

Choosing the Right Aluminum Filter Drier for Your Refrigeration Needs

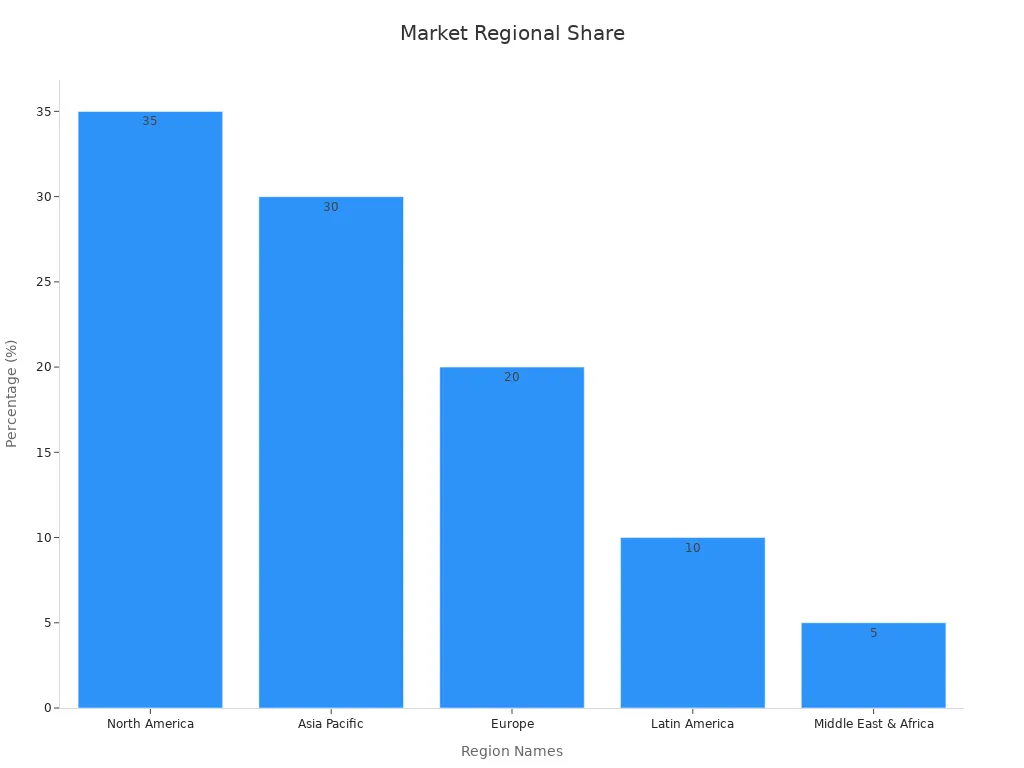

Selecting the right refrigeration systems aluminum Filter Drier requires careful attention to system compatibility, filtration efficiency, and moisture removal capacity. Industry data shows that the global market for filter driers continues to expand, driven by rising HVACR demand and stricter environmental regulations. The table below highlights key market statistics:

| Aspect | Details |

|---|---|

| Market Size 2024 | USD 150 Million |

| Projected Market Size 2033 | USD 220 Million |

| CAGR (2026-2033) | 4.5% |

| Regional Market Share (2023) | North America 35%, Asia Pacific 30%, Europe 20%, Latin America 10%, Middle East & Africa 5% |

A properly chosen filter drier boosts system performance, protects components, and extends equipment lifespan.

Key Takeaways

- Aluminum filter driers remove moisture and contaminants to protect refrigeration systems and improve performance.

- Choose a filter drier that matches your system’s refrigerant type, pressure rating, and flow capacity for safe and efficient operation.

- Proper installation and regular maintenance, including timely replacement, prevent system failures and extend equipment life.

- Single tube filter driers suit small systems, while double tube models handle larger, high-capacity refrigeration needs.

- Select filter driers with recognized certifications and buy from reliable suppliers to ensure quality and long-term system protection.

Refrigeration Systems Aluminum Filter Drier: Function and Importance

What Is an Aluminum Filter Drier?

An aluminum filter drieris a specialized component designed for use in refrigeration and air conditioning systems. It removes moisture, acid, and particulate contaminants from the refrigerant. Manufacturers use high-quality aluminum to construct these filter driers, which provides excellent corrosion resistance and lightweight properties. The internal core often contains a Molecular Sieve, a material that absorbs moisture and prevents chemical reactions within the system. This design ensures that the refrigerant remains clean and dry, which is essential for efficient operation.

Aluminum filter driers come in various sizes and configurations to suit different system requirements. Technicians select the appropriate model based on system capacity, refrigerant type, and pressure rating. The use of aluminum also allows for better heat dissipation and durability, making these filter driers a preferred choice in modern refrigeration systems.

The Role in Refrigeration Systems

The refrigeration systems aluminum filter drier plays a critical role in maintaining system reliability and performance. Its main function is to protect the compressor and other components from damage caused by moisture and contaminants. When moisture enters the system, it can react with refrigerants and oils, leading to acid formation and corrosion. This process often results in system failure and costly repairs.

Tip: Regular replacement of the filter drier helps prevent moisture buildup and extends the lifespan of refrigeration equipment.

Key benefits of using a high-quality aluminum filter drier include:

- Superior moisture absorption, which keeps refrigerants free from water and prevents acid formation.

- Compatibility with modern synthetic oils such as PVE, POE, and PAG, ensuring chemical stability and structural integrity.

- Effective control of moisture, which prevents oil hydrolysis and acid-related failures.

- Support for new-generation refrigerants, including hydrocarbons and hydrofluoroolefins, meeting environmental standards.

- High filtration efficiency, corrosion resistance, and shock resistance, as confirmed by laboratory tests and industry certifications.

These features demonstrate how the filter drier maintains optimal refrigerant conditions and prevents system failures. By choosing the right filter drier, technicians ensure long-term system efficiency and reliability.

Key Selection Criteria for Refrigeration Systems Aluminum Filter Drier

System Compatibility: Refrigerant Types and Pressure Ratings

Selecting the right filter drier starts with system compatibility. Every refrigeration system operates with specific refrigerant types and pressure requirements. Technicians must match the filter drier to the refrigerant in use, such as R134a, R404A, or newer low-GWP blends. Each refrigerant has unique chemical properties that interact differently with filter drier materials. Using an incompatible filter drier can lead to chemical reactions, reduced efficiency, or even system failure.

Pressure rating is another critical factor. The filter drier must withstand the maximum operating pressure of the system. Manufacturers specify pressure ratings to ensure safety and reliability. For example, many high-quality aluminum filter driers support working pressures up to 45 bar, making them suitable for both traditional and modern refrigeration applications. Always check the manufacturer’s specifications to confirm compatibility with both refrigerant type and system pressure.

Tip: Always verify the filter drier’s compatibility with A2L refrigerants and ensure it meets the latest safety standards for your application.

Filtration Efficiency and Moisture Removal

Filtration efficiency and moisture removal define the core performance of any filter drier. These features protect compressors and other sensitive components from debris and water contamination. Industry standards, such as ANSI/ASHRAE Standard 63.2-2017, provide laboratory methods to evaluate how well filter driers remove and retain solid particles. The table below summarizes key standards relevant to filtration efficiency:

| Standard / Test Method | Focus Area | Description | Applicability to Aluminum Filter Driers |

|---|---|---|---|

| ANSI/ASHRAE Standard 63.2-2017 | Filtration efficiency | Laboratory test evaluating removal and retention of solid particles by liquid-line filters and driers. | Applicable to hermetic refrigerant liquid-line filter driers, including aluminum types. |

| ISO 14085-3:2015 | Filtration efficiency and retention capacity | Measures filtration efficiency of hydraulic filter elements under steady or cyclic flow conditions. | Relevant for comparative understanding; not specific to aluminum filter driers. |

| ISO 19438:2003 | Filtration efficiency and contaminant retention | Multi-pass test for fuel filters measuring particulate removal and contaminant capacity at constant flow. | Applicable to fuel filters; may provide comparative insights but not specific to aluminum filter driers. |

Filtration efficiency ensures that particles such as brazing chips, dust, and rust do not circulate within the system. Moisture removal is equally important. Moisture can cause corrosion, acid formation, and eventual system breakdown. High-quality filter driers use molecular sieves to adsorb water and activated alumina to neutralize acids. These features keep the refrigerant clean and dry, supporting long-term system reliability.

Build Quality and Certifications

Build quality and certifications set apart reliable filter driers from substandard options. Manufacturers use advanced materials and construction techniques to ensure durability and performance. For example, leading filter driers feature molecular sieves for moisture adsorption, activated alumina for acid removal, and multiple filtration layers such as fibrous media and glass wool. These design elements target both particulate and chemical contaminants.

Certifications validate the product’s safety and compliance with international standards. Many reputable filter driers carry UL certification, PED Directive 2014/68/EU compliance, and leak testing for refrigerant conformity. Some models are compatible with A2L refrigerants and have ATEX certification in process. Operating temperature ranges from -40°C to +70°C, and connection sizes vary from 1/4” to 1-1/8” to fit different system requirements. These certifications and features ensure that the refrigeration systems aluminum filter drier performs reliably in demanding environments.

Note: Certified filter driers provide peace of mind by meeting rigorous safety and performance standards. Always choose products with recognized certifications for critical refrigeration applications.

Installation and Maintenance Considerations

Proper installation and regular maintenance ensure the filter drier performs at its best. Technicians must follow best practices during both processes to maximize system reliability and efficiency.

Installation Best Practices

A successful installation starts with careful preparation. Technicians should inspect the filter drier for any visible damage before opening the packaging. Cleanliness is critical. Any debris or moisture introduced during installation can compromise system performance.

Key steps for installation:

-

System Preparation:

Evacuate the refrigeration system completely. Remove all traces of moisture and contaminants before installing the new filter drier. -

Correct Orientation:

Install the filter drier in the liquid line, as close as possible to the expansion valve or capillary tube. The arrow on the body indicates the correct flow direction. -

Proper Brazing Techniques:

Use a wet rag or heat sink to protect the filter drier from excessive heat during brazing. Overheating can damage the internal desiccant and reduce moisture removal capacity. -

Leak Testing:

After installation, perform a thorough leak test. Use nitrogen or another inert gas to pressurize the system and check all joints for leaks.

Tip: Always use new filter driers after opening the refrigeration system for repairs or component replacement. Reusing old filter driers can introduce contaminants and moisture.

Maintenance Guidelines

Routine maintenance extends the lifespan of both the filter drier and the entire refrigeration system. Technicians should monitor system performance and replace the filter drier at recommended intervals.

Maintenance checklist:

-

Visual Inspection:

Check for signs of corrosion, swelling, or oil stains on the filter drier. These may indicate internal blockage or moisture saturation. -

Pressure Drop Monitoring:

Measure the pressure drop across the filter drier. A significant increase suggests clogging or restricted flow, signaling the need for replacement. -

Scheduled Replacement:

Replace the filter drier during major service events, such as compressor changes or after a system burnout. Manufacturers often recommend replacement every 12 to 24 months, depending on operating conditions. -

System Cleanliness:

Keep the surrounding area clean during maintenance. Prevent dirt and moisture from entering the system when removing or installing the filter drier.

| Maintenance Task | Frequency | Purpose |

|---|---|---|

| Visual Inspection | Every 6 months | Detect early signs of failure |

| Pressure Drop Check | Every 6 months | Identify flow restrictions |

| Scheduled Replacement | 12-24 months | Ensure optimal moisture and contaminant removal |

| Leak Testing | After each service | Maintain system integrity |

Note: Following a consistent maintenance schedule helps prevent costly breakdowns and ensures the refrigeration system operates efficiently.

Common Installation and Maintenance Mistakes

Technicians sometimes overlook important details during installation or maintenance. Avoiding these mistakes can save time and prevent system failures.

- Failing to purge the system with nitrogen during brazing, which can cause internal oxidation.

- Installing the filter drier in the wrong orientation, leading to restricted flow.

- Neglecting to replace the filter drier after a compressor burnout or major repair.

- Using excessive heat during installation, which can damage the desiccant core.

🛠️ Alert: Always consult the manufacturer’s installation manual for specific instructions and recommended practices.

By following these guidelines, technicians help ensure the filter drier delivers reliable protection and supports long-term system performance.

Single Tube vs. Double Tube Aluminum Filter Drier Options

Features of Single Tube Aluminum Filter Driers

Single tube aluminum filter driers offer a straightforward design. Manufacturers typically use a single inlet and outlet, which simplifies installation. These filter driers suit small to medium refrigeration systems. The compact structure allows for easy integration into tight spaces. Technicians often select single tube models for applications where space and weight matter. The single flow path ensures consistent refrigerant movement and reliable filtration.

Key advantages include:

- Simple installation process

- Lightweight and compact form

- Cost-effective for standard refrigeration units

- Reliable performance in low to moderate capacity systems

Tip: Single tube filter driers work well in residential refrigerators, small commercial coolers, and air conditioning units.

Features of Double Tube Aluminum Filter Driers

Double tube aluminum filter driers feature two parallel flow paths. This design increases filtration capacity and supports higher refrigerant flow rates. Double tube models often serve larger or more complex refrigeration systems. The dual-tube structure enhances moisture and contaminant removal, which helps protect sensitive components.

Notable features:

- Higher flow capacity for demanding systems

- Improved filtration and moisture removal

- Suitable for commercial and industrial refrigeration

- Enhanced durability due to robust construction

A table below summarizes the main differences:

| Feature | Single Tube | Double Tube |

|---|---|---|

| Flow Capacity | Standard | High |

| Installation | Simple | Requires more space |

| Application | Small/Medium Systems | Large/Industrial Systems |

| Filtration Efficiency | Standard | Enhanced |

Choosing Between Single and Double Tube Designs

Selecting between single tube and double tube aluminum filter driers depends on system requirements. Technicians assess system size, refrigerant flow, and installation space. Single tube models fit compact systems with moderate demands. Double tube options serve high-capacity or mission-critical applications. System designers should consider future maintenance and replacement needs. Proper selection ensures optimal performance and long-term reliability.

🛠️ Note: Always consult manufacturer guidelines to match the filter drier design to your specific refrigeration system.

Comparing Features and Benefits of Refrigeration Systems Aluminum Filter Drier

Common Specifications and Performance Factors

Industry benchmarks help buyers compare aluminum filter driers across brands and models. Manufacturers focus on several key specifications to ensure optimal system protection and efficiency. The table below summarizes the most important performance factors:

| Benchmark / Specification | Description | Impact / Example |

|---|---|---|

| Moisture Removal Capacity | High-performance desiccants like molecular sieves and activated alumina absorb moisture efficiently | Absorbs up to 20% more moisture than conventional models, extending system lifespan and efficiency |

| Pressure Drop | Optimized flow paths reduce resistance to refrigerant flow | Reduces pressure drop by up to 30%, improving energy efficiency and lowering operational costs |

| Overall Lifespan | Advanced materials and desiccants enhance durability | Longer operational life reduces maintenance and replacement frequency |

| Materials | Advanced aluminum alloys and polymer composites improve corrosion resistance and thermal conductivity | Improves durability and thermal performance |

| Nanotechnology | Increases surface area of filter media for better filtration and moisture absorption | Enhances energy performance by up to 15% |

| Eco-friendly Materials | Use of biodegradable polymers and recyclable metals | Supports sustainability and regulatory compliance |

| Application Versatility | Tailored designs for residential, commercial, and industrial systems | Ensures optimal performance across diverse environments |

These specifications allow system designers to select the right filter drier for each application. High moisture removal capacity and low pressure drop remain top priorities for most users.

Reliability and Longevity

Aluminum filter driers deliver proven reliability in demanding refrigeration environments. Manufacturers use advanced desiccants such as molecular sieves to prevent moisture-related freezing and acid formation. Brazed construction techniques increase durability and reduce the risk of leaks. Regular inspection and timely replacement maximize the effectiveness of these components. Sight-glass moisture indicators help technicians detect contamination early, allowing for proactive maintenance.

- High-quality filter driers protect compressors and evaporators from corrosion and debris.

- Proper sealing and controlled refrigerant storage maintain filter drier performance.

- Routine maintenance, including inspection and replacement, extends equipment lifespan and reduces unexpected downtime.

🛡️ Tip: Consistent use of reliable filter driers supports long-term system protection and minimizes costly repairs.

Cost-Effectiveness and Value

Cost-effectiveness goes beyond the initial purchase price. Aluminum filter driers offer value through extended service intervals, reduced maintenance, and improved energy efficiency. Modern designs use a blend of molecular sieve and activated alumina to maximize both moisture and acid adsorption. Filtration efficiency, often optimized at a 25-micron rating, balances contaminant capture with minimal pressure drop. Manufacturers select solid core designs and advanced materials to ensure durability and performance.

Buyers benefit from:

- Fewer replacements due to longer operational life

- Lower energy consumption from reduced pressure drop

- Enhanced protection for sensitive system components

💡 Note: Selecting a filter drier with high moisture adsorption and robust construction delivers long-term savings and reliable system operation.

Evaluating Chinese Suppliers for Refrigeration Systems Aluminum Filter Drier

What to Look for in a Supplier

Buyers should evaluate several factors when selecting a Chinese supplier for refrigeration systems aluminum filter drier products. A reputable supplier demonstrates a strong track record in the refrigeration industry. Years of experience, a broad product portfolio, and a commitment to customer satisfaction signal reliability. Companies that invest in research and development often deliver innovative solutions and adapt to changing market needs.

A supplier with integrated design, production, and after-sales service can provide better support throughout the product lifecycle. Responsive communication and technical assistance help resolve issues quickly. Many buyers also value suppliers who offer customization options to meet specific system requirements.

📝 Tip: Request references or case studies from potential suppliers to verify their experience and performance in real-world applications.

Quality Assurance and Certifications

Quality assurance remains a top priority when sourcing refrigeration components. Leading Chinese manufacturers implement strict quality control processes at every production stage. They use advanced testing equipment to ensure each filter drier meets industry standards for performance and safety.

Certifications provide additional confidence. Look for suppliers with ISO9001 quality management certification, UL certification for the US market, and compliance with EU ROHS directives. These credentials confirm that the supplier follows international best practices and delivers products that meet regulatory requirements.

| Certification | Description | Importance |

|---|---|---|

| ISO9001 | Quality management system | Ensures consistent product quality |

| UL | US safety certification | Required for North American sales |

| EU ROHS | Environmental compliance | Confirms eco-friendly production |

Tips for Sourcing and Ordering

Effective sourcing strategies help buyers secure high-quality refrigeration systems aluminum filter drier products from China. Start by comparing multiple suppliers and reviewing their product specifications. Request product samples to evaluate build quality and compatibility with your system.

Clear communication of technical requirements reduces the risk of errors. Confirm lead times, minimum order quantities, and shipping arrangements before placing an order. Reliable suppliers provide transparent pricing and detailed documentation.

📦 Note: Establish long-term partnerships with trusted suppliers to ensure consistent supply and ongoing technical support.

Selecting the right refrigeration systems aluminum filter drier depends on matching system needs with product features. Decision-makers should review specifications such as flow capacity, pressure, and refrigerant compatibility. The table below shows how model ranges align with system requirements:

| Model Range | Flow Capacity (SCFM) | Refrigerant Types | Max Pressure (PSIG) |

|---|---|---|---|

| RAD-0025A to 0150A | 25–150 | R134a | 232 |

| RAD-0200A to 0600A | 200–600 | R134a, R404a, R449a | 232 |

| RAD-0750A to 2000A | 750–2000 | R449a, R404a | 232 |

Professionals recommend consulting trusted suppliers and prioritizing certified products for long-term protection.

FAQ

What is the main function of an aluminum filter drier in refrigeration systems?

An aluminum filter drier removes moisture and contaminants from the refrigerant. This process protects compressors and other components, ensuring efficient and reliable system operation.

How often should technicians replace an aluminum filter drier?

Technicians should replace the filter drier every 12 to 24 months or during major service events. Regular replacement prevents moisture buildup and maintains system performance.

Can aluminum filter driers work with all refrigerant types?

Most aluminum filter driers support a wide range of refrigerants, including R134a, R404A, and new low-GWP blends. Always check the manufacturer’s specifications for compatibility.

What certifications should buyers look for when selecting a filter drier?

Buyers should look for ISO9001, UL, and EU ROHS certifications. These certifications confirm product quality, safety, and environmental compliance.

Why choose a Chinese supplier for aluminum filter driers?

Chinese suppliers often provide advanced manufacturing, competitive pricing, and a broad product range. Many offer international certifications and strong after-sales support.