Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

Auditing a Filter Drier Factory: 10 Checklist Items for B2B Buyers

Auditing a Filter Drier factory plays a critical role in ensuring the production of high-quality and reliable components. For B2B buyers, a structured checklist provides a systematic way to evaluate factories and identify areas for improvement.

A well-designed audit checklist offers several advantages:

- Consistency: Promotes uniformity in processes, ensuring better quality control.

- Error Reduction: Minimizes mistakes through a structured approach.

- Efficiency: Streamlines operations, enabling quick identification of gaps.

- Accountability: Clarifies team responsibilities, boosting reliability.

- Data Tracking and Analysis: Facilitates performance monitoring over time.

- Compliance: Ensures adherence to industry standards and regulations.

This meticulous approach is especially vital when evaluating components like a copper filter drier for refrigerator freezer parts, where precision and compliance directly impact performance and safety.

Key Takeaways

- Use a clear checklist to check filter drier factories. This helps you make better and smarter choices.

- Check for important certifications like ISO 9001 and ROHS. These show the factory follows rules and makes good products.

- Look at where materials come from and how they are tracked. This ensures parts like copper filter driers are good and dependable.

- Make sure the factory treats workers fairly. Paying fair wages and keeping workers safe makes them happier and work better.

- Review the factory's quality checks. Careful testing helps avoid mistakes and keeps products safe.

- Ask about how the factory ships products. Fast and organized delivery makes customers happy and builds trust.

- See if the factory is always trying to improve. Factories that change and get better stay ahead of others.

- Ask for customer reviews and feedback. This helps you learn how well the factory works and if it’s reliable.

Factory Certifications and Compliance

Importance of Certifications

Certifications validate a factory’s adherence to industry standards and best practices. They demonstrate a commitment to quality, operational reliability, and customer satisfaction. Certified factories often outperform their non-certified counterparts in areas such as production efficiency, defect management, and workforce training.

Certification also fosters trust among B2B buyers, ensuring that products meet stringent requirements for safety and performance. For components like a copper filter drier for refrigerator freezer parts, certifications guarantee compliance with technical specifications critical to refrigeration systems.

Studies highlight the correlation between certifications and operational reliability:

- Certification improves performance across industries and company sizes.

- Enhanced customer satisfaction and quality management are linked to certification.

- Positive effects on personnel management and training have been documented.

Key Certifications to Verify

B2B buyers should prioritize verifying certifications that align with industry standards and regulatory requirements. Key certifications include:

- ISO 9001: Ensures robust quality management systems.

- ROHS Compliance: Confirms adherence to environmental protection directives.

- UL Certification: Validates product safety for global markets.

| Study | Findings |

|---|---|

| Poksinska (2010) | Organizations may vary in maturity for standardizing operations, affecting certification outcomes. |

| Aba et al. (2016) | Certified companies show better performance than non-certified ones over a five-year period. |

| Santos and Millán (2013) | Certification significantly impacts continuous improvement, which is crucial for operational reliability. |

Factories with these certifications demonstrate their ability to produce reliable and high-quality refrigeration components. Buyers should request documentation and verify its authenticity during audits.

Compliance with Environmental and Safety Standards

Compliance with environmental and safety standards is essential for sustainable operations. Factories must adhere to regulations that minimize environmental impact and ensure worker safety. This includes proper waste management, energy-efficient processes, and adherence to occupational health standards.

Factories that comply with these standards not only reduce their ecological footprint but also enhance their reputation among environmentally conscious buyers. For example, ROHS certification ensures that products are free from hazardous substances, aligning with global environmental directives.

Safety compliance also plays a critical role in maintaining operational stability. Factories that prioritize worker safety through training programs and protective measures reduce risks and improve productivity. Buyers should assess these practices during audits to ensure long-term reliability and ethical operations.

Ethical Labor Practices

Ethical labor practices form a cornerstone of responsible manufacturing. For B2B buyers, evaluating a factory’s commitment to fair labor standards ensures alignment with corporate values and global expectations. Factories that prioritize ethical labor practices not only protect their workforce but also enhance their reputation in the marketplace.

Key Aspects of Ethical Labor Practices

-

Fair Wages and Benefits

Workers should receive compensation that meets or exceeds the legal minimum wage. Factories must also provide essential benefits, such as health insurance, paid leave, and retirement plans. Buyers should verify payroll records and employee contracts to confirm compliance. -

Safe Working Conditions

A safe workplace minimizes risks and promotes productivity. Factories must adhere to occupational safety standards, including proper ventilation, protective equipment, and emergency protocols. Regular safety audits and employee training programs further demonstrate a commitment to worker well-being. -

Prohibition of Child and Forced Labor

Ethical factories strictly prohibit child labor and any form of forced or bonded labor. Buyers should review hiring policies and conduct on-site inspections to ensure compliance with international labor laws, such as those outlined by the International Labour Organization (ILO). -

Non-Discrimination Policies

Factories must foster an inclusive environment where workers are treated equally, regardless of gender, race, religion, or other personal characteristics. Policies against discrimination and harassment should be clearly documented and enforced.

Why Ethical Labor Practices Matter

Ethical labor practices are not just a moral obligation; they are a business imperative. Factories that treat their workforce fairly often experience higher employee retention, improved morale, and better overall productivity.

For B2B buyers, partnering with such factories reduces the risk of reputational damage and ensures compliance with global supply chain standards. Ethical practices also resonate with end consumers, who increasingly demand transparency and fairness in the products they purchase.

How to Assess Ethical Labor Practices

Buyers can evaluate ethical labor practices through:

- On-Site Visits: Observe working conditions and interact with employees.

- Documentation Review: Examine policies, payroll records, and safety certifications.

- Third-Party Audits: Engage independent organizations to verify compliance with labor standards.

| Indicator | What to Look For |

|---|---|

| Fair Wages | Payroll records, employee interviews |

| Safe Conditions | Safety equipment, emergency exits, training logs |

| Non-Discrimination | Written policies, grievance mechanisms |

Factories that uphold ethical labor practices demonstrate their commitment to social responsibility. This commitment not only benefits workers but also strengthens partnerships with buyers who value integrity and fairness.

Raw Material Quality

Sourcing and Traceability

The quality of raw materials directly impacts the performance and durability of refrigeration components. Buyers should evaluate the factory’s sourcing practices to ensure materials come from reputable suppliers. Factories that maintain strong relationships with trusted vendors often achieve higher consistency in their products.

Traceability is another critical factor. Factories must implement systems to track raw materials from procurement to production. This ensures accountability and allows for quick identification of issues in the supply chain. For instance, a robust traceability system can help pinpoint the origin of copper used in a copper filter drier for refrigerator freezer parts, ensuring compliance with industry standards.

Tip: During audits, request documentation that outlines the sourcing process and traceability measures. This provides insight into the factory’s commitment to quality and transparency.

Consistency in Material Quality

Consistency in raw material quality is essential for producing reliable refrigeration components. Factories must conduct regular inspections and testing to verify that materials meet predefined specifications. This includes evaluating properties such as tensile strength, corrosion resistance, and thermal conductivity.

Factories that prioritize consistency often implement standardized quality control protocols. These protocols may include sampling procedures, material certifications, and third-party testing. For example, copper used in refrigeration components must exhibit uniformity to ensure optimal performance in demanding environments.

Buyers should assess the factory’s quality assurance processes during audits. Look for evidence of routine material testing and adherence to strict quality benchmarks. Factories that consistently meet these standards demonstrate their ability to deliver high-quality products.

Adherence to Specifications for Copper Filter Drier for Refrigerator Freezer Parts

Adherence to technical specifications is non-negotiable when manufacturing components like a copper filter drier for refrigerator freezer parts. These specifications ensure compatibility with refrigeration systems and compliance with safety standards. Factories must follow precise guidelines for dimensions, material composition, and performance characteristics.

During audits, buyers should verify that the factory adheres to these specifications at every stage of production. This includes reviewing design blueprints, inspecting finished products, and confirming compliance with industry certifications. Factories that meet these requirements not only produce reliable components but also reduce the risk of operational failures in end-use applications.

Note: Partnering with a factory that prioritizes adherence to specifications enhances product reliability and strengthens the buyer-supplier relationship.

Manufacturing Processes

Overview of Production Methods

Modern filter drier factories employ advanced production methods to ensure consistent quality and efficiency. These methods often include automated assembly lines, precision welding, and computer-aided design (CAD) systems. Automation reduces human error and enhances productivity, while CAD ensures that components like the copper filter drier for refrigerator freezer parts meet exact specifications.

Factories also adopt lean manufacturing principles to minimize waste and optimize resource utilization. Techniques such as just-in-time (JIT) production and value stream mapping streamline workflows and reduce lead times. These practices not only improve operational efficiency but also contribute to cost savings, which can be passed on to buyers.

Machinery and Equipment Maintenance

Well-maintained machinery forms the backbone of any manufacturing process. Regular maintenance ensures that equipment operates at peak performance, reducing the risk of breakdowns and production delays. Factories often implement preventive maintenance schedules, which include routine inspections, lubrication, and part replacements.

Advanced monitoring systems, such as sensors and IoT-enabled devices, allow factories to track equipment performance in real time. These systems detect anomalies early, enabling timely interventions. For example, a factory producing refrigeration components can use vibration analysis to identify potential issues in welding machines, ensuring uninterrupted production.

Buyers auditing a factory should assess the maintenance logs and inquire about the frequency of equipment servicing. A factory with a robust maintenance program demonstrates its commitment to reliability and quality.

Efficiency and Precision in Processes

Efficiency and precision are critical in manufacturing high-performance components. Factories achieve these goals by integrating advanced technologies such as statistical process control (SPC) and predictive analytics. These tools help monitor production parameters and maintain tight tolerances, ensuring that every product meets the required standards.

The benefits of these methods are evident across industries. For instance, a precision parts manufacturer using polynomial regression models achieved a 43% reduction in out-of-specification parts, saving $245,000 in rework costs. Similarly, a medical device manufacturer employing SPC systems reduced quality-related downtime by 37%, resulting in $520,000 in savings.

| Case Study | Method Used | Improvement Achieved |

|---|---|---|

| Precision Parts Manufacturer | Polynomial Regression Models | 43% reduction in out-of-specification parts, $245,000 reduction in rework costs |

| Medical Device Manufacturer | SPC System | 37% reduction in quality-related downtime, $520,000 savings |

| Food Processing Company | Predictive Regression Models | 7% increase in throughput, 3.2% reduction in energy consumption |

For components like the copper filter drier for refrigerator freezer parts, precision in processes ensures optimal performance and durability. Buyers should evaluate the factory’s use of advanced production techniques and their impact on product quality.

Quality Control Systems

Testing Protocols and Standards

Testing protocols form the foundation of any robust quality control system. Factories producing refrigeration components, such as copper filter driers, must implement rigorous testing standards to ensure product reliability and safety. These protocols often include performance testing, durability assessments, and compliance checks against industry benchmarks.

Standardized testing procedures help identify potential defects early in the production cycle. For example, pressure testing ensures that copper filter driers can withstand operational stress without failure. Similarly, leak detection tests verify the integrity of seals and joints, preventing refrigerant loss during use.

Factories that adopt international testing standards, such as ISO 2859 for sampling procedures, demonstrate their commitment to quality. Buyers should evaluate the factory’s testing facilities and request documentation of testing protocols during audits. This ensures that the factory consistently delivers products that meet or exceed expectations.

Defect Management Systems

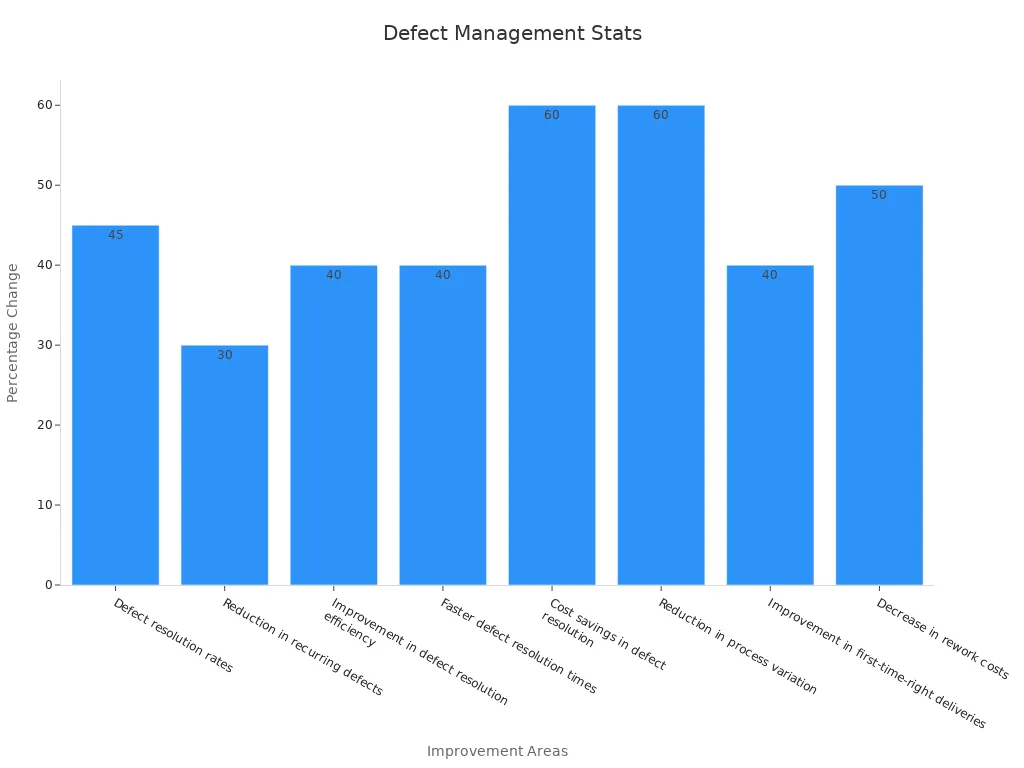

Effective defect management systems are critical for maintaining high-quality production standards. These systems enable factories to identify, analyze, and resolve defects efficiently, minimizing disruptions and ensuring product reliability.

Structured reporting mechanisms play a pivotal role in defect resolution. Factories that implement thorough root cause analysis can reduce recurring defects by 30%. Integrated defect tracking systems further enhance efficiency, leading to a 40% improvement in defect resolution times and a 50% decrease in rework costs.

| Improvement Area | Statistic |

|---|---|

| Defect resolution rates | 45% better with structured reporting |

| Reduction in recurring defects | 30% with thorough root cause analysis |

| Improvement in defect resolution efficiency | 40% within six months with robust systems |

| Faster defect resolution times | 40% faster with integrated approaches |

| Cost savings in defect resolution | Up to 60% through shift-left testing |

| Reduction in process variation | 60% with integrated defect tracking |

| Improvement in first-time-right deliveries | 40% with integrated defect tracking |

| Decrease in rework costs | 50% with integrated defect tracking |

Buyers should assess the factory’s defect management practices during audits. This includes reviewing defect logs, analyzing resolution timelines, and verifying the use of advanced tracking tools. Factories with robust defect management systems consistently deliver higher-quality products and reduce operational costs.

Continuous Improvement Practices

Continuous improvement practices ensure that factories remain competitive and adapt to evolving industry demands. These practices involve regularly evaluating processes, identifying inefficiencies, and implementing corrective actions to enhance overall performance.

Factories often use methodologies like Six Sigma and Kaizen to drive continuous improvement. Six Sigma focuses on reducing process variation, while Kaizen emphasizes incremental changes for sustained growth. For example, a factory adopting Six Sigma principles can achieve a 60% reduction in process variation, leading to more consistent product quality.

Employee involvement is another key aspect of continuous improvement. Factories that encourage workforce participation in problem-solving initiatives often experience higher innovation rates and improved morale. Buyers should inquire about the factory’s improvement programs and review case studies or performance metrics to gauge their effectiveness.

Tip: Partnering with a factory that prioritizes continuous improvement ensures long-term reliability and innovation, benefiting both buyers and end-users.

Supply Chain Management

Vendor Relationships and Reliability

Strong vendor relationships form the backbone of an efficient supply chain. Factories that collaborate with reliable vendors ensure a steady supply of high-quality raw materials, minimizing disruptions in production. Buyers should evaluate the factory's vendor selection criteria, focusing on factors such as supplier reputation, delivery consistency, and adherence to quality standards.

Factories that maintain long-term partnerships with trusted vendors often benefit from preferential pricing, faster lead times, and improved communication. These advantages translate into better cost management and timely production schedules. Buyers auditing a factory should request a list of key suppliers and assess their track records for reliability and performance.

Tip: Factories with diversified vendor networks reduce the risk of supply chain disruptions caused by unforeseen events, such as material shortages or geopolitical issues.

Inventory Management Systems

Effective inventory management systems ensure that factories maintain optimal stock levels, avoiding overstocking or shortages. Advanced systems, such as Enterprise Resource Planning (ERP) software, enable factories to monitor inventory in real time, track material usage, and forecast demand accurately.

Factories with optimized inventory systems experience significant operational benefits:

- 30% improvement in order fulfillment rates, reducing delivery delays.

- Enhanced visibility into stock levels, minimizing waste and inefficiencies.

- Faster response times to sudden changes in demand.

Buyers should inquire about the factory's inventory management practices during audits. This includes reviewing software capabilities, stock turnover rates, and replenishment strategies. Factories that leverage data-driven tools demonstrate their commitment to efficiency and customer satisfaction.

Logistics and Delivery Capabilities

Logistics and delivery capabilities play a critical role in ensuring that products reach buyers on time and in excellent condition. Factories with robust logistics systems streamline the movement of goods from production to distribution, reducing transit times and costs.

Key factors to assess include:

- Packaging Standards: Proper packaging protects components like copper filter driers during transit, preventing damage.

- Shipping Partnerships: Factories that collaborate with reliable carriers ensure consistent delivery performance.

- Tracking Systems: Real-time tracking provides transparency and allows buyers to monitor shipments.

Buyers should also evaluate the factory's ability to handle international shipping requirements, such as customs documentation and compliance with export regulations. Factories with well-established logistics networks enhance buyer confidence by delivering products efficiently and reliably.

Note: Factories that prioritize logistics optimization often achieve higher customer satisfaction rates, strengthening their position as preferred suppliers.

Workforce Expertise

Employee Qualifications and Training

A factory’s workforce expertise directly impacts the quality of its products. Skilled employees ensure precision in manufacturing processes and adherence to industry standards. Buyers should evaluate the qualifications and training programs offered to workers during factory audits.

Factories that prioritize employee development often implement structured training programs. These programs cover technical skills, safety protocols, and quality assurance practices. For example, workers handling copper filter driers for refrigerator freezer parts must understand material properties, welding techniques, and testing procedures.

Tip: Ask factories to provide documentation of training schedules, certifications, and performance evaluations. This demonstrates their commitment to workforce excellence.

Key indicators of employee qualifications include:

- Technical Certifications: Workers with certifications in refrigeration systems or welding techniques bring specialized expertise.

- On-the-Job Training: Factories that offer hands-on training ensure employees gain practical experience.

- Continuous Education: Programs that update workers on new technologies and industry trends enhance their adaptability.

A well-trained workforce reduces errors, improves efficiency, and ensures consistent product quality. Buyers should prioritize factories that invest in employee education and skill development.

Workforce Retention and Experience

Employee retention reflects a factory’s ability to maintain a stable and experienced workforce. High retention rates indicate job satisfaction, effective management, and a positive work environment. Buyers should assess workforce retention during audits to gauge operational reliability.

Experienced workers contribute to higher productivity and fewer defects. Factories with long-tenured employees benefit from institutional knowledge, which enhances process optimization and problem-solving capabilities. For instance, a factory producing refrigeration components may rely on veteran technicians to troubleshoot complex machinery issues.

Note: Factories with low turnover rates often deliver consistent quality, as experienced employees require less supervision and training.

Indicators of workforce retention include:

- Average Tenure: Longer average tenure suggests stability and expertise.

- Employee Feedback: Positive feedback highlights satisfaction and engagement.

- Retention Programs: Initiatives like performance incentives and career growth opportunities improve loyalty.

Buyers should inquire about retention strategies and review employee satisfaction surveys. Factories that prioritize workforce retention demonstrate their commitment to operational excellence.

Commitment to Quality Maintenance

A factory’s dedication to quality maintenance ensures long-term reliability and customer satisfaction. Workforce expertise plays a critical role in sustaining high standards. Buyers should evaluate how factories integrate quality maintenance into daily operations.

Factories committed to quality maintenance often adopt proactive measures. These include regular inspections, preventive maintenance schedules, and employee accountability programs. Workers trained in quality control protocols can identify issues early, reducing defects and downtime.

Callout: Factories that emphasize quality maintenance deliver products that consistently meet buyer expectations.

Key practices include:

- Standard Operating Procedures (SOPs): Clear guidelines ensure uniformity in processes.

- Quality Audits: Routine audits verify adherence to specifications and standards.

- Employee Involvement: Workers engaged in quality initiatives contribute to continuous improvement.

Buyers should assess the factory’s quality maintenance practices during audits. Factories that prioritize these measures enhance product reliability and strengthen buyer confidence.

Production Capacity and Scalability

Meeting Current Volume Requirements

A factory’s ability to meet current production demands is a critical factor for B2B buyers. Buyers should assess whether the factory can consistently deliver the required volume of products without compromising quality or timelines. This evaluation involves reviewing production schedules, output data, and resource allocation.

Factories that operate at optimal capacity often implement advanced planning systems, such as Material Requirements Planning (MRP) or Enterprise Resource Planning (ERP) software. These tools help streamline workflows, allocate resources efficiently, and minimize bottlenecks. For example, a factory producing copper filter driers for refrigerator freezer parts may use ERP systems to synchronize material procurement with production schedules, ensuring timely delivery.

Tip: Buyers should request production reports and observe operations during peak demand periods. This provides insight into the factory’s ability to handle high-volume orders reliably.

Scalability for Future Growth

Scalability reflects a factory’s potential to expand operations in response to increased demand. Buyers should evaluate whether the factory has the infrastructure, workforce, and technology to scale production without significant delays or additional costs.

Key indicators of scalability include:

- Facility Size: Factories with room for additional machinery or assembly lines can scale more easily.

- Workforce Flexibility: A cross-trained workforce can adapt to new roles as production needs grow.

- Technology Investments: Factories that adopt modular equipment or automation systems can expand capacity with minimal disruption.

For instance, a factory equipped with modular welding machines can quickly add units to increase output. Similarly, factories that maintain strong vendor relationships can secure additional raw materials during periods of high demand. Buyers should inquire about the factory’s expansion plans and review past performance during growth phases.

Note: Partnering with a scalable factory ensures long-term reliability, especially for buyers planning to increase order volumes in the future.

Operational Flexibility

Operational flexibility enables factories to adapt to changing requirements, such as custom orders, design modifications, or urgent deadlines. Buyers should assess whether the factory can adjust production schedules, reconfigure assembly lines, or accommodate special requests without significant delays.

Factories with flexible operations often employ lean manufacturing principles. Techniques like Just-in-Time (JIT) production and quick changeover systems allow factories to switch between product types efficiently. For example, a factory producing refrigeration components may use quick-change tooling to transition from one product line to another within hours.

Callout: Flexible factories reduce lead times and improve responsiveness, making them ideal partners for dynamic markets.

Buyers should evaluate the factory’s track record in handling custom orders or last-minute changes. This includes reviewing case studies, interviewing key personnel, and observing production processes during audits. Factories that demonstrate operational flexibility provide a competitive advantage by meeting diverse buyer needs effectively.

Packaging and Logistics

Packaging Standards for Copper Filter Drier for Refrigerator Freezer Parts

Packaging plays a vital role in preserving the integrity of refrigeration components during transit. Factories must adhere to strict packaging standards to ensure that products like copper filter driers for refrigerator freezer parts remain undamaged and functional upon delivery. Buyers should evaluate the factory’s packaging practices to confirm compliance with industry requirements.

Effective packaging involves using durable materials that protect against physical impact, moisture, and temperature fluctuations. Factories often employ multi-layered packaging solutions, including corrugated boxes, foam inserts, and vacuum-sealed bags. These materials shield sensitive components from external stressors, ensuring their reliability in end-use applications.

Buyers should also assess labeling practices during audits. Proper labeling provides critical information, such as product specifications, handling instructions, and batch numbers. This enhances traceability and simplifies inventory management for buyers. Factories that prioritize clear and accurate labeling demonstrate their commitment to quality and customer satisfaction.

Ensuring Product Safety During Transit

Product safety during transit is essential for maintaining the quality of refrigeration components. Factories must implement measures to prevent damage caused by vibration, stacking pressure, or environmental conditions. Buyers should inquire about the factory’s shipping protocols to ensure that products arrive in optimal condition.

Factories often use shock-absorbing materials and reinforced packaging to mitigate transit risks. For example, copper filter driers for refrigerator freezer parts may be packed with foam padding to prevent movement within the box. Additionally, factories may employ temperature-controlled containers for shipments to regions with extreme climates.

Tip: Buyers should request documentation of transit safety measures, such as drop tests and vibration simulations. These tests validate the factory’s ability to protect products during transportation.

Tracking systems also play a crucial role in ensuring product safety. Real-time tracking allows buyers to monitor shipments and address potential issues promptly. Factories that integrate tracking technology into their logistics operations enhance transparency and build trust with buyers.

Delivery Efficiency and Timeliness

Timely delivery is a cornerstone of successful B2B partnerships. Factories must demonstrate their ability to meet delivery deadlines consistently, even during peak demand periods. Buyers should evaluate the factory’s logistics capabilities to ensure reliable and efficient service.

Key factors influencing delivery efficiency include route optimization, carrier partnerships, and inventory management. Factories that collaborate with reputable shipping companies often achieve faster transit times and lower costs. Additionally, advanced inventory systems enable factories to prepare shipments promptly, reducing lead times.

Buyers should also assess the factory’s ability to handle international shipping requirements. This includes compliance with customs regulations, accurate documentation, and familiarity with export procedures. Factories with robust international logistics networks minimize delays and ensure smooth delivery across borders.

Callout: Partnering with a factory that prioritizes delivery efficiency strengthens buyer confidence and enhances supply chain reliability.

Customer References and Reviews

Requesting and Verifying Client References

Client references provide valuable insights into a factory’s performance and reliability. Buyers should request references from previous or current clients during the audit process. Factories that willingly share references demonstrate transparency and confidence in their operations.

To verify references, buyers can contact the listed clients directly. Questions should focus on key areas such as product quality, delivery timelines, and responsiveness to issues. For example, asking about the consistency of copper filter driers for refrigerator freezer parts can reveal the factory’s commitment to quality.

Tip: Request references from clients in similar industries or with comparable order volumes. This ensures the feedback aligns with the buyer’s specific needs.

Buyers should also cross-check references with publicly available information, such as company websites or industry reports. Factories with positive references from reputable clients often exhibit higher reliability and professionalism.

Analyzing Feedback from Other B2B Clients

Feedback from other B2B clients offers a broader perspective on the factory’s reputation. Buyers should analyze reviews and testimonials available on platforms like industry forums, trade directories, or social media. These sources often highlight recurring strengths and weaknesses in the factory’s operations.

A structured approach to feedback analysis can help buyers identify patterns. For instance:

- Positive Indicators: Consistent praise for product quality, timely deliveries, and responsive customer service.

- Negative Indicators: Complaints about delayed shipments, inconsistent quality, or lack of communication.

| Feedback Type | What It Reveals |

|---|---|

| Positive Testimonials | Reliability, professionalism, and quality |

| Neutral Comments | Areas for improvement or minor concerns |

| Negative Reviews | Potential risks or operational weaknesses |

Buyers should prioritize feedback from verified sources to ensure accuracy. Factories with a high volume of positive reviews from B2B clients often deliver consistent results and maintain strong partnerships.

Indicators of Reliability and Trustworthiness

Reliability and trustworthiness are critical factors in selecting a factory. Buyers should look for specific indicators during audits and reference checks. These include:

- Longevity in the Industry: Factories with decades of experience, like Ningbo Taojun Refrigeration Equipment Co., Ltd., often exhibit stability and expertise.

- Partnerships with Reputable Brands: Collaborations with well-known companies signal credibility and high standards.

- Repeat Business: A high percentage of returning clients reflects satisfaction and trust.

- Certifications and Awards: Recognition from industry bodies reinforces the factory’s reliability.

Callout: Factories that consistently meet deadlines, maintain quality, and resolve issues promptly build trust with their clients.

Buyers should combine these indicators with direct feedback from references and reviews. Factories that excel in reliability and trustworthiness strengthen buyer confidence and foster long-term partnerships.

Innovation and R&D

Commitment to Research and Development

Research and development (R&D) drive progress in filter drier manufacturing. Factories investing in R&D improve product quality, optimize processes, and meet evolving market demands. Buyers should assess a factory’s dedication to R&D during audits to gauge its ability to innovate and adapt.

Factories with strong R&D programs often allocate resources to developing new materials, refining designs, and enhancing production techniques. These efforts result in products with superior performance and reliability. For example, copper filter driers for refrigerator freezer parts benefit from R&D through improved filtration efficiency and durability.

A 10% increase in R&D spending leads to a 1.7% rise in the probability of innovation. This investment significantly impacts product innovation, which directly enhances competitive positioning. Additionally, innovative sales increase by 1.6% for every 10% boost in R&D spending.

Buyers should inquire about the factory’s R&D initiatives, including recent projects, patents, and collaborations with research institutions. Factories committed to R&D demonstrate their ability to stay ahead in a competitive industry.

Adoption of Advanced Technologies

Advanced technologies transform filter drier manufacturing by improving efficiency, reliability, and product performance. Buyers should evaluate a factory’s adoption of cutting-edge tools and systems during audits.

Modern factories integrate smart technologies, such as IoT-enabled sensors and predictive maintenance systems, into their operations. These innovations allow real-time monitoring and proactive service, reducing operational costs and enhancing customer satisfaction. Additionally, advanced materials and filtration designs improve product capabilities, meeting the demands of refrigeration systems.

| Evidence Description | Impact on Competitive Edge |

|---|---|

| Manufacturers are developing filter driers with improved filtration capabilities. | Enhances product performance, meeting evolving market demands. |

| Integration of smart technologies and advanced materials in design. | Increases reliability and efficiency, providing a technological advantage. |

| Real-time monitoring and predictive maintenance through IoT and smart sensors. | Allows for proactive service, reducing operational costs and improving customer satisfaction. |

| Focus on innovation and differentiation in product offerings. | Helps manufacturers stand out in a competitive landscape, attracting more customers. |

Factories leveraging these technologies gain a competitive edge by delivering high-quality products efficiently. Buyers should assess the factory’s technological infrastructure and its impact on production quality.

Competitive Edge Through Innovation

Innovation sets leading factories apart in the filter drier industry. Buyers should prioritize factories that focus on differentiation and continuous improvement to maintain a competitive edge.

Innovative factories often introduce unique product features, such as enhanced filtration systems or eco-friendly designs. These advancements attract buyers seeking reliable and sustainable solutions. Additionally, factories that innovate in production processes reduce costs and improve efficiency, benefiting both manufacturers and clients.

Factories emphasizing innovation and differentiation stand out in competitive markets. Their ability to adapt to industry trends and customer needs strengthens their position as preferred suppliers.

Buyers should evaluate the factory’s track record in innovation, including product launches, awards, and partnerships with industry leaders. Factories that prioritize innovation deliver superior value and foster long-term relationships with buyers.

Auditing a filter drier factory with a structured 10-item checklist ensures thorough evaluation and informed decision-making. This approach empowers B2B buyers to assess critical factors such as certifications, raw material quality, and production capacity.

Key Takeaway: A comprehensive checklist minimizes risks, enhances product reliability, and fosters long-term partnerships.

By leveraging this tool, buyers secure high-quality refrigeration components while aligning with industry standards. This systematic evaluation process strengthens supply chains and supports sustainable business growth.

FAQ

What certifications should a filter drier factory have?

Buyers should verify certifications like ISO 9001 for quality management, ROHS for environmental compliance, and UL for product safety. These certifications ensure the factory adheres to global standards and produces reliable components.

How can buyers assess raw material quality during an audit?

Buyers should request documentation on sourcing practices and traceability systems. On-site inspections of raw materials, such as copper, can confirm consistency and adherence to specifications.

Tip: Ask for third-party testing reports to validate material quality.

Why is workforce expertise important in filter drier manufacturing?

Skilled employees ensure precision in production and adherence to quality standards. Factories with structured training programs and experienced workers deliver consistent, high-quality products.

How do factories ensure product safety during transit?

Factories use durable packaging materials, shock-absorbing inserts, and proper labeling to protect products. Advanced tracking systems provide real-time updates, ensuring safe and timely delivery.

What role does R&D play in filter drier manufacturing?

Research and development drive innovation, improve product performance, and optimize manufacturing processes. Factories investing in R&D stay competitive and meet evolving market demands.

How can buyers verify a factory’s scalability?

Buyers should review production reports, facility size, and workforce flexibility. Factories with modular equipment and strong vendor relationships can scale operations efficiently.

What testing protocols should a factory follow?

Factories should implement rigorous testing, including pressure tests, leak detection, and durability assessments. Adherence to international standards like ISO 2859 ensures product reliability.

Callout: Testing protocols reduce defects and enhance product safety.

How can buyers evaluate a factory’s logistics capabilities?

Buyers should assess shipping partnerships, route optimization, and compliance with export regulations. Factories with robust logistics systems ensure timely and efficient deliveries.

Note: Reliable logistics strengthen supply chain efficiency and buyer confidence.