Author:

-

Position:

General Manager of Foreign Trade Department, Taojun Refrigeration -

Professional Experience:

Engaged in international trade within the refrigeration industry since 2004.

Expert in brand strategy and omni-channel marketing, having led three multi-million yuan projects that boosted brand exposure by over 200%.

-

Core Competencies:

Proficient in data analysis and user growth strategies.

Skilled in SEO/SEM and social media management tools.

Experienced in cross-departmental collaboration and team leadership.

-

Philosophy:

"Data-driven decisions, creativity-powered branding." Committed to achieving business value and user experience excellence through refined operations. -

Vision:

Eager to collaborate with partners to explore emerging market opportunities and set industry benchmark cases.

Contact Us to Find More Products

Air Conditioner Copper Filter Driers: Customization Options for OEM Partners

Customization plays a pivotal role in the design of air conditioner copper Filter Driers for OEM partners. Tailored solutions allow HVAC systems to achieve optimal performance by addressing specific operational needs.

- Technological advancements in filter driers enhance energy efficiency, directly improving HVAC system functionality.

- Customized components ensure compatibility with unique system designs, meeting diverse requirements.

- The growing focus on environmental sustainability underscores the need for precise and efficient filter drier configurations.

By integrating these innovations, OEMs can deliver superior products that align with modern industry demands.

Key Takeaways

- Custom designs make HVAC systems work better and more efficiently.

- Special filter driers fit new refrigerants, lowering failure risks and boosting performance.

- Choosing custom options saves money over time by cutting repair costs.

- Unique branding and packaging help OEMs shine in busy markets and keep customers loyal.

- Working with makers helps OEMs meet market needs and grow with new ideas.

Understanding Air Conditioner Copper Filter Driers

What Are Air Conditioner Copper Filter Driers?

Air conditioner copper filter driers are essential components in HVAC systems, designed to maintain the efficiency and reliability of refrigeration cycles. These devices filter out contaminants and moisture from the refrigerant, ensuring smooth operation and preventing damage to critical system parts. Manufactured from refrigeration-grade copper tubing and Molecular Sieve, they are particularly suited for low-vibration systems. Their compact design makes them economical replacements for steel driers, provided proper installation techniques are followed.

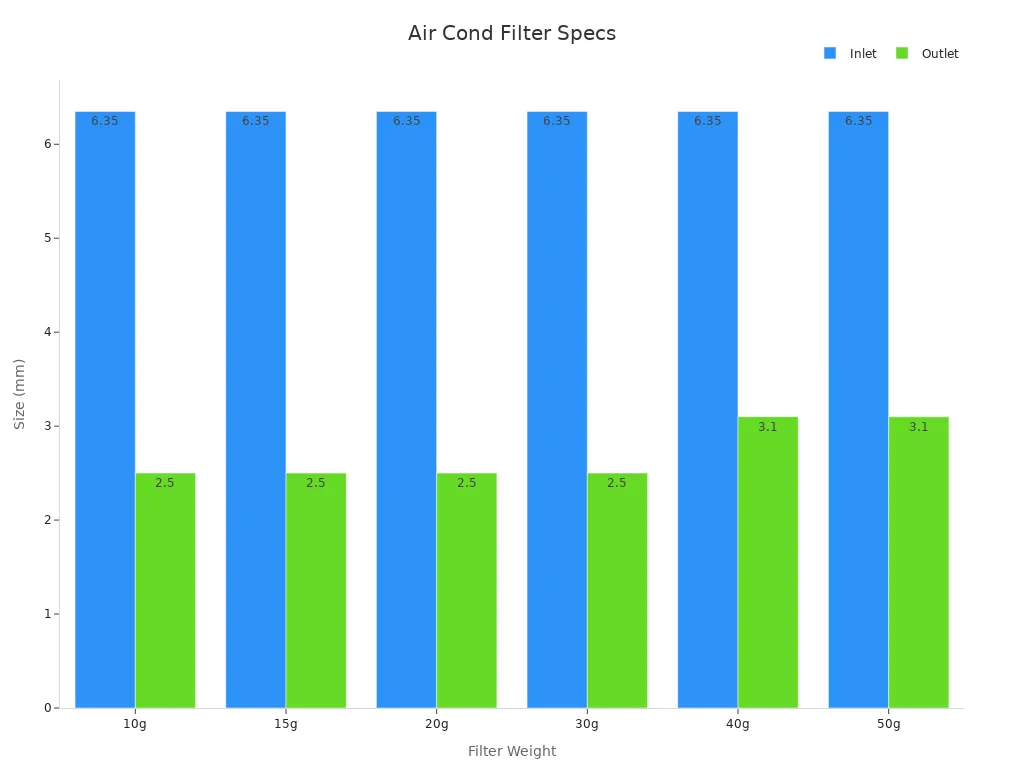

Copper filter driers come in various sizes and specifications to meet diverse system requirements. Below is a table showcasing technical specifications for modern copper filter driers:

| Gram | Size (Dia*Length) | Inlet | Outlet |

|---|---|---|---|

| 10g | 16*113mm | 6.35mm | 2.5mm |

| 15g | 19*115mm | 6.35mm | 2.5mm |

| 20g | 24*125mm | 6.35mm | 2.5mm |

| 30g | 24*140mm | 6.35mm | 2.5mm |

| 40g | 24*170mm | 6.35mm | 3.1mm |

| 50g | 29*160mm | 6.35mm | 3.1mm |

These specifications highlight the adaptability of copper filter driers for various HVAC applications, ensuring compatibility with different system designs.

Functions in HVAC Systems

Copper filter driers play a pivotal role in HVAC operations by filtering and drying refrigerants. They prevent moisture and contaminants from damaging key components such as compressors and expansion valves. By absorbing water vapor, they eliminate the risk of freezing and corrosion within the system. Additionally, they trap solid particles to avoid blockages, ensuring uninterrupted refrigerant flow.

These devices also neutralize acids formed from chemical reactions, safeguarding the system against long-term damage. Without a functioning filter drier, issues like moisture accumulation and clogs can compromise system efficiency, leading to increased energy consumption and potential compressor failure. Regular maintenance and timely replacement of filter driers are critical to avoiding costly repairs and ensuring optimal performance.

Why Customization Is Essential for OEM Partners

Addressing Performance Optimization

Customization allows OEM partners to achieve superior performance in HVAC systems by tailoring filter driers to specific operational needs. Optimized designs enhance filtration processes, ensuring contaminants and moisture are effectively removed from refrigerants. This leads to improved energy efficiency and prolonged equipment lifespan. For instance, custom filter driers can adjust refrigerant flow in real-time, maintaining consistent cooling even under varying conditions.

| Aspect | Description |

|---|---|

| Enhanced Efficiency | Customized filter driers improve overall system efficiency by optimizing filtration processes. |

| Compatibility | They are designed to work with a variety of refrigerants, ensuring broader application use. |

| Application Requirements | Custom solutions meet specific needs that standard products cannot address, enhancing performance. |

By addressing unique application requirements, customized air conditioner copper filter driers ensure HVAC systems operate at peak efficiency, meeting the demands of modern industrial and residential cooling systems.

Ensuring Cost-Effectiveness

Although customization may involve higher initial costs, it offers significant long-term savings. Tailored components streamline production processes, reduce material waste, and optimize system efficiency. For example, a custom-designed assembly line can minimize labor and manufacturing time, lowering overall production expenses. Additionally, customized filter driers reduce the risk of system failures, cutting down on repair and replacement costs. This approach ensures OEM partners can deliver high-quality products while maintaining cost-effectiveness.

Achieving System Compatibility

Custom filter driers enhance compatibility with modern HVAC systems by addressing specific technical requirements. Molecular sieves, for example, outperform traditional materials like activated alumina in moisture absorption, reducing the risk of acid formation. They also maintain structural integrity when exposed to advanced oils such as PVE, POE, and PAG, ensuring stable performance across diverse applications.

- Enhanced Moisture Absorption: Molecular sieves trap moisture more effectively, preventing corrosion and freezing.

- Improved Stability with Modern Oils: These materials remain durable when exposed to synthetic oils, ensuring consistent operation.

- Long-Term Reliability: Custom configurations resist degradation, making them ideal for high-temperature, high-moisture environments.

By ensuring compatibility with the latest refrigerants and oils, customized filter driers provide OEM partners with reliable solutions that meet evolving industry standards.

Customization Options for Air Conditioner Copper Filter Driers

Material and Design Variations

Material and design variations significantly impact the performance and durability of air conditioner copper filter driers. Manufacturers offer two primary configurations: solid core with steel housing and loose desiccant with spun copper tubing. Each option caters to specific operational needs and system requirements.

| Feature | Solid Core with Steel Housing | Loose Desiccant with Spun copper tube |

|---|---|---|

| Moisture Adsorption Capacity | Higher (up to 3 times lower moisture level) | Lower (up to 10% moisture content) |

| Filtration Capacity | Effective down to 25 microns | Effective down to 15 microns |

| Maximum Working Pressure (MWP) | Up to 46 bar (667 psi) | Around 24 bar (348 psi) |

| Total Cost of Ownership | Higher initial cost, lower maintenance | Lower initial cost, higher maintenance |

Solid core designs excel in high-pressure environments, offering superior moisture retention and acid removal capabilities. These features make them ideal for industrial HVAC systems requiring robust performance. On the other hand, loose desiccant designs provide cost-effective solutions for residential applications, where lower pressure and maintenance demands are common.

Manufacturers are increasingly adopting advanced materials like molecular sieves and high-strength copper tubing to enhance the efficiency and reliability of filter driers. These innovations align with the growing demand for customized solutions in both residential and industrial markets.

Desiccant Selection for Specific Applications

Selecting the right desiccant is crucial for optimizing the performance of air conditioner copper filter driers. Research highlights the effectiveness of liquid desiccant systems (LDS) in removing moisture from HVAC systems. Commonly used desiccants include calcium chloride (CaCl2), lithium chloride (LiCl), and lithium bromide (LiBr). Among these, CaCl2 stands out as the most cost-effective and widely available option.

Key factors influencing desiccant performance include air inlet temperature, flow rate, and desiccant concentration. For example, higher concentrations of CaCl2 improve moisture absorption rates, making it suitable for high-humidity environments. Lithium-based desiccants, while more expensive, offer enhanced stability and efficiency in extreme temperature conditions.

Emerging trends in desiccant technology focus on eco-friendly and energy-efficient solutions. Manufacturers are developing desiccants that work seamlessly with modern refrigerants, ensuring compatibility and long-term reliability. These advancements enable OEM partners to meet the evolving demands of the HVAC industry while maintaining environmental sustainability.

Filtration Capabilities for Refrigerants and Contaminants

Filtration capabilities are a critical aspect of air conditioner copper filter driers, ensuring the removal of contaminants and maintaining system efficiency. Advanced filter driers incorporate a blend of desiccants and molded core designs to maximize filtration performance.

| Evidence Description | Details |

|---|---|

| Acid Removal Ability | The Catch-All Filter-Drier’s desiccant has superior acid removal ability compared to other desiccants used in refrigeration driers. |

| Field Performance | Demonstrated excellent performance in cleaning contaminated systems and protecting new systems from acid and lubricant breakdown products. |

| Removal of Lubricant Breakdown Products | Only the desiccant in the Catch-All Filter-Driers was capable of removing products of lubricant decomposition in tests. |

| Blend of Desiccants | A specially formulated blend of desiccants provides maximum contaminant removal characteristics. |

| Molded Core Design | The molded porous core ensures uniform porosity for maximum filtration ability. |

| Leakproof Design | The shell is welded and pressure tested to ensure it is leak-proof. |

Modern filter driers are designed to handle a wide range of refrigerants, including eco-friendly options like R-410A and R-32. These refrigerants require specialized filtration to manage moisture and acid removal effectively. Additionally, the integration of smart technologies allows real-time monitoring of filtration performance, enabling proactive maintenance and reducing system downtime.

The shift towards energy-efficient and environmentally friendly HVAC systems has driven the development of advanced filtration technologies. Customized filter driers equipped with high-performance desiccants and robust designs ensure optimal system performance and longevity.

Connection Types and Sizes

Connection types and sizes play a critical role in the functionality and compatibility of air conditioner copper filter driers. Manufacturers offer a range of connection options to meet the diverse requirements of HVAC systems, ensuring seamless integration and optimal performance.

Common Connection Types

- Flare Connections: These connections are widely used for their ease of installation and reliable sealing. They are ideal for systems requiring frequent maintenance or replacement.

- Solder Connections: Known for their durability, solder connections provide a permanent bond that withstands high-pressure environments.

- Threaded Connections: These connections offer flexibility and are suitable for systems with varying pressure levels.

Standard Sizes

Filter driers are available in multiple sizes to accommodate different refrigerant flow rates and system capacities. Common inlet and outlet diameters include 6.35 mm, 9.52 mm, and 12.7 mm, ensuring compatibility with a broad range of HVAC applications.

Products adhere to industry standards such as cULus and ASTM B280, guaranteeing reliability and safety. These certifications ensure that connection types and sizes meet stringent quality requirements, providing OEM partners with confidence in their system designs.

Selecting the appropriate connection type and size is essential for maintaining system efficiency and preventing leaks or pressure drops. Manufacturers work closely with OEM partners to customize these features, ensuring compatibility with unique system configurations.

Branding and Packaging Customization

Branding and packaging customization offer OEM partners a powerful tool to differentiate their products in competitive markets. By tailoring these elements, manufacturers help OEMs establish a strong brand identity and enhance customer experience.

Branding Strategies

Effective branding transforms air conditioner copper filter driers into recognizable products that resonate with consumers. Manufacturers can incorporate OEM logos, unique color schemes, and custom labeling to align with brand aesthetics. For example:

- Apple emphasizes sleek design and innovative technology, creating a loyal customer base through consistent branding.

- Nike uses minimalist packaging that reflects quality and performance, enhancing the overall brand experience.

Packaging Customization

Packaging serves both functional and aesthetic purposes. Custom designs can include eco-friendly materials, compact dimensions for efficient storage, and visually appealing layouts that attract attention. These features not only improve product presentation but also reinforce the brand's commitment to sustainability and quality.

Tailored branding and packaging create a lasting impression on customers, fostering trust and loyalty. OEM partners benefit from increased market visibility and differentiation, driving long-term success.

Benefits of Customizing Air Conditioner Copper Filter Driers

Enhanced System Efficiency

Customizing air conditioner copper filter driers significantly improves system efficiency by addressing specific operational needs. Tailored designs optimize the filtration and drying processes, ensuring contaminants and moisture are effectively removed from refrigerants. This reduces the risk of blockages, corrosion, and acid formation, which can compromise system performance.

Key performance enhancements include:

- The integration of high-efficiency variable-speed compressors, which improve energy utilization.

- Advanced filter-driers that absorb and filter contaminants, maintaining smooth refrigerant flow.

- Copper coil tubing paired with enhanced aluminum fins, which increases the heat absorption area and facilitates energy-efficient heat transfer.

These improvements not only enhance cooling performance but also reduce energy consumption, making HVAC systems more sustainable and cost-effective. Customized solutions ensure that each component works harmoniously within the system, delivering consistent and reliable results.

Prolonged Product Lifespan

Customized filter driers contribute to the longevity of HVAC systems by minimizing wear and tear on critical components. By effectively removing moisture and contaminants, these tailored solutions prevent damage to compressors, expansion valves, and other sensitive parts. This reduces the likelihood of system failures and extends the overall lifespan of the equipment.

For example, in industrial applications like semiconductor manufacturing, custom-engineered filter driers protect sensitive equipment from contaminants and acid formation. Similarly, in energy-efficient systems, these components reduce compressor workload, saving up to 240 operational hours annually per unit. This not only lowers maintenance costs but also ensures long-term reliability.

Additionally, predictive servicing alerts integrated into customized designs enable proactive maintenance. A pilot project in German cold chain logistics demonstrated a 31% reduction in maintenance costs through such innovations. These advancements highlight the value of customization in achieving durable and efficient HVAC systems.

Strengthened Brand Identity for OEMs

Customization offers OEM partners a unique opportunity to strengthen their brand identity in competitive markets. Tailored products allow manufacturers to differentiate themselves by meeting specific customer needs and preferences. This fosters customer loyalty and enhances market recognition.

| Benefit | Explanation |

|---|---|

| Differentiation | Customization helps OEMs stand out in a crowded market by creating unique selling propositions. |

| Meeting Customer Needs | Tailored products meet the specific preferences of individual customers, enhancing satisfaction. |

| Increased Customer Loyalty | Customized offerings lead to higher satisfaction, fostering loyalty and repeat business. |

| Design Customization | Modifying product appearance and branding helps reflect brand identity and differentiate in the market. |

| Improved Brand Recognition | Unique and personalized options enhance brand recall, making it easier for customers to remember the brand. |

For instance, OEMs can incorporate custom branding elements such as logos, color schemes, and packaging designs to align with their brand image. These efforts not only improve product presentation but also create a lasting impression on customers. By offering tailored solutions, OEMs can position themselves as industry leaders, driving long-term success and market growth.

Collaborating with Manufacturers for Custom Solutions

Identifying Customization Needs

Identifying customization needs is the first step in creating tailored air conditioner copper filter driers. Manufacturers must understand the specific goals and challenges of each facility to deliver effective solutions. This process ensures that the final product aligns with operational requirements and avoids costly errors.

- Tailored solutions enhance client satisfaction by addressing unique facility goals.

- Customization ensures successful outcomes in critical environments like healthcare and manufacturing, where precise HVAC performance is essential.

- Responsive relationships between manufacturers and OEM partners foster quicker collaborations and a deeper understanding of future needs.

In industries such as healthcare and pharmaceuticals, HVAC systems must meet strict regulatory standards. Customization ensures these systems operate efficiently without compromising safety or quality. By focusing on these needs, manufacturers can create products that deliver both reliability and compliance.

Communicating Design and Performance Specifications

Effective communication is vital for conveying design and performance specifications to manufacturers. Clear and detailed instructions eliminate ambiguity and ensure the final product meets expectations.

- Detailed specifications should include dimensions, materials, tolerances, and finishes.

- Visual aids like sketches, 3D models, or CAD drawings help convey design intent.

- Physical prototypes allow manufacturers to understand product mechanics and user interaction.

- A feedback loop ensures open communication throughout the production process.

- Legal agreements, such as NDAs, protect designs and outline expectations.

Clarity in language is crucial, especially when discussing technical terms. By using these frameworks, OEM partners can collaborate effectively with manufacturers, ensuring the final product aligns with their vision.

Reviewing Prototypes and Conducting Tests

Prototypes play a critical role in validating the performance of custom filter driers. Testing protocols ensure that the product meets all design and operational requirements before full-scale production begins.

- Define test objectives to verify individual components or subsystems.

- Identify test cases that address specific performance parameters, such as moisture absorption and filtration efficiency.

- Specify the testing environment and tools, including pressure gauges and flow meters.

- Establish pass/fail criteria to measure performance against predefined metrics.

- Document the testing steps, starting with simple tests and progressing to more complex evaluations.

Thorough testing ensures that prototypes meet quality standards and perform reliably under real-world conditions. This process minimizes risks and guarantees that the final product delivers optimal results.

Scaling Production for Market Demand

Manufacturers of air conditioner copper filter driers must adapt their production strategies to meet increasing market demand. Scaling production involves optimizing processes, enhancing capacity, and ensuring consistent quality across large volumes. This approach allows manufacturers to address the growing needs of OEM partners while maintaining efficiency and reliability.

Market Growth and Demand Trends

The HVAC industry continues to expand, driven by rising demand for energy-efficient systems and customized components. Projections indicate significant growth in the global market for refrigeration and air conditioning accessories.

| Metric | Value |

|---|---|

| Estimated Market Size 2024 | USD 939.7 Billion |

| Projected Market Size 2031 | USD 1356.9 Billion |

| CAGR (2024-2031) | 4.7% |

These figures highlight the importance of scaling production to capitalize on market opportunities. Manufacturers must align their operations with this upward trajectory to remain competitive and meet OEM requirements effectively.

Strategies for Scaling Production

- Automation and Advanced Machinery: Incorporating automated systems and high-precision equipment enhances production speed and accuracy. These technologies reduce labor costs and minimize errors, ensuring consistent product quality.

- Flexible Manufacturing Systems: Adopting flexible systems allows manufacturers to adjust production volumes based on fluctuating demand. This adaptability ensures efficient resource utilization and reduces downtime.

- Supplier Collaboration: Building strong relationships with suppliers ensures a steady flow of raw materials, preventing delays in production. Reliable supply chains support scalability and maintain operational continuity.

- Quality Assurance Protocols: Implementing rigorous quality checks at every stage of production guarantees that scaled operations do not compromise product reliability.

Scaling production requires a balance between increasing output and maintaining high standards. Manufacturers who invest in advanced technologies and streamlined processes can meet market demand while delivering superior products.

Benefits for OEM Partners

OEM partners benefit significantly from scaled production. Increased manufacturing capacity ensures timely delivery of customized filter driers, supporting their ability to meet customer expectations. Additionally, economies of scale reduce production costs, enabling OEMs to offer competitive pricing without sacrificing quality.

By scaling production effectively, manufacturers position themselves as reliable partners in the HVAC industry, fostering long-term collaborations and driving mutual growth.

Customization in air conditioner copper filter driers empowers OEM partners to deliver HVAC systems that excel in efficiency, reliability, and adaptability. Tailored solutions address unique operational needs, ensuring compatibility with modern refrigerants and advanced system designs. Comparative analyses highlight the advantages of customized configurations, such as a 20% efficiency boost in upgraded systems in Lafayette, LA, and enhanced comfort in residential buildings in Montreal.

Collaboration with manufacturers unlocks opportunities for process optimization, cost savings, and improved product quality. For instance, custom solutions enhance equipment performance, enabling multi-purpose operations and reducing production costs. By partnering with experienced manufacturers, OEMs can align their products with market demands, fostering long-term growth and innovation.

Tailored filter driers not only meet technical requirements but also strengthen brand identity, positioning OEMs as leaders in the HVAC industry.

FAQ

What is the primary purpose of copper filter driers in HVAC systems?

Copper filter driers remove moisture and contaminants from refrigerants. This prevents corrosion, acid formation, and blockages, ensuring smooth operation and extending the lifespan of HVAC systems.

Can OEM partners customize copper filter driers for specific refrigerants?

Yes, manufacturers offer tailored solutions for refrigerants like R-410A and R-32. Customization ensures optimal filtration and compatibility with modern eco-friendly refrigerants.

How does branding customization benefit OEM partners?

Branding customization enhances product recognition and strengthens market presence. Manufacturers incorporate logos, color schemes, and packaging designs to align with OEM brand identity.

Are custom filter driers compatible with high-pressure systems?

Manufacturers design solid core filter driers to withstand high-pressure environments. These configurations ensure durability and reliable performance in industrial HVAC applications.

What factors influence the choice of desiccants in filter driers?

Desiccant selection depends on moisture absorption capacity, stability under extreme conditions, and compatibility with refrigerants. Calcium chloride and lithium-based desiccants are common options for diverse applications.