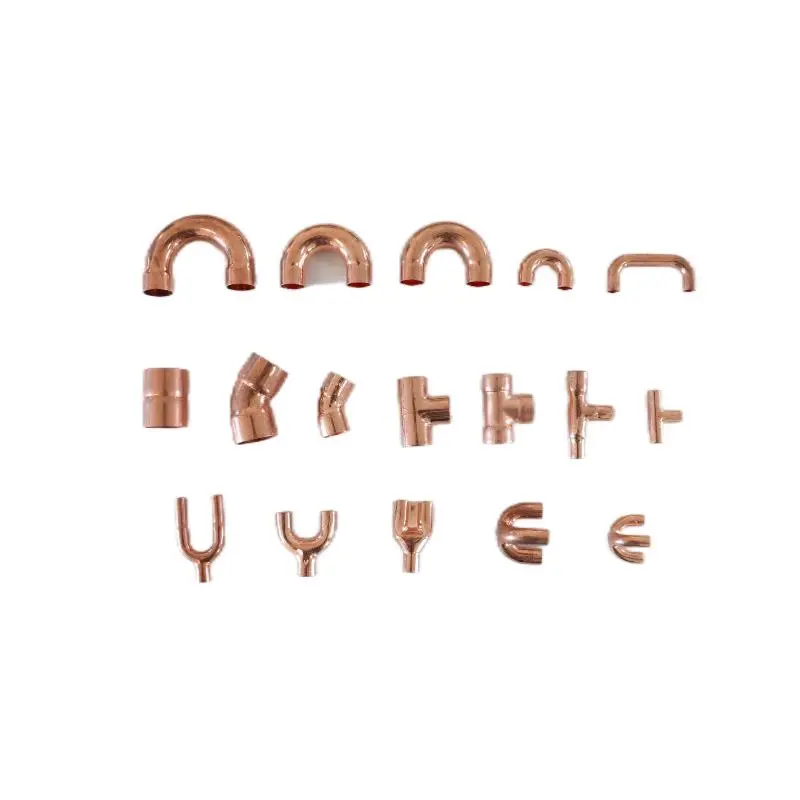

High-Quality Brass and Copper Fittings from Top Chinese Factories & Suppliers

When it comes to high-quality mixing brass and copper fittings, reliability and performance are essential. As a leading manufacturer in China, we specialize in producing premium fittings that adhere to international standards. Our facility, Ningbo Taojun Refrigeration Equipment Co., Ltd., utilizes advanced technology to ensure precision and durability in each product. Our mixing brass and copper fittings offer exceptional corrosion resistance and thermal conductivity, making them ideal for various refrigeration and plumbing applications. We are committed to quality and detail, ensuring that our products surpass your expectations. For B2B purchasers seeking dependable fittings to enhance your inventory, we are dedicated to providing outstanding service and top-notch quality. Let's collaborate to meet your requirements effectively.Must-Know Tips For Mixing Brass And Copper Fittings Your Trusted OEM Partner Winning in 2025

Mixing brass and copper fittings can be a challenge for many in the industry, especially for global buyers looking for reliable solutions. At Ningbo Taojun Refrigeration Equipment Co., Ltd., we understand these challenges, having specialized in refrigeration equipment manufacturing since 1988. Our rich heritage, starting as Xiangshan Refrigeration Accessories Factory of Zhejiang University, gives us deep insights into quality and innovation in material combinations. When considering the integration of brass and copper fittings, it’s crucial to ensure compatibility in terms of corrosion resistance and thermal conductivity. Proper sealing techniques and the use of appropriate joint compounds can prevent leaks and prolong the lifespan of your systems. Regular maintenance and inspections are also essential to identify any wear and tear that may result from the unique characteristics of these metals. As we approach 2025, staying ahead in these best practices is vital for maintaining your competitive edge in the market. As your trusted OEM partner, we at Taojun are committed to providing high-quality components that meet industry standards. By leveraging our extensive experience and innovative approaches, we empower our partners to succeed in their endeavors. With our support, you can confidently mix brass and copper fittings, ensuring your projects are not only successful but also sustainable. Let us work together to navigate these complexities and achieve your operational goals.

Must-Know Tips For Mixing Brass And Copper Fittings Your Trusted OEM Partner Winning in 2025

| Tip | Description | Importance Level | Recommended Practices |

|---|---|---|---|

| Choose the Right Fittings | Ensure compatibility between brass and copper materials. | High | Use fittings specified for mixed materials. |

| Check for Corrosion Issues | Identify potential for galvanic corrosion when mixing metals. | Medium | Use protective coatings if necessary. |

| Proper Joining Techniques | Utilize recommended soldering or brazing methods. | High | Follow guidelines for thermal expansion. |

| Regular Maintenance | Inspect fittings regularly for leaks and corrosion. | Medium | Schedule routine checks and repairs. |

| Educate Your Team | Provide resources on best practices for mixing materials. | High | Conduct training sessions and workshops. |

Insider Tips For Mixing Brass And Copper Fittings Industry Giant Manufacturers You Can Rely On

N

Nancy Lewis

Incredible quality! Support was timely and efficient, making my experience seamless.

10 May 2025

S

Sandra Bell

Amazing product! The after-sales support team was professional and understanding.

28 May 2025

G

Gonzalo Thomas

Impressive product quality and very professional after-sales support!

10 May 2025

H

Harry Howard

Impressed with the quality! Customer service was exemplary and highly proficient.

03 June 2025

S

Scott Wright

Fantastic product! The after-sales team is knowledgeable and responsive.

06 June 2025

K

Kimberly King

Exceptional quality! I appreciated the professionalism of the support staff.

19 May 2025