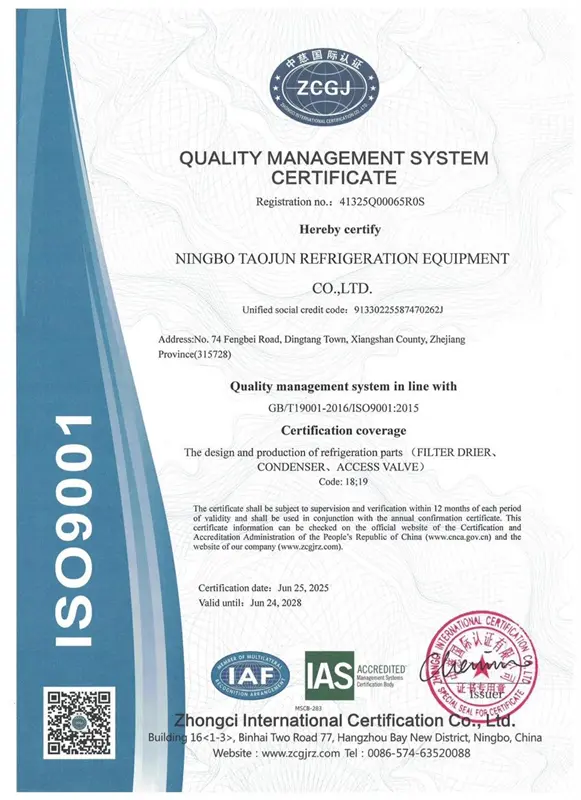

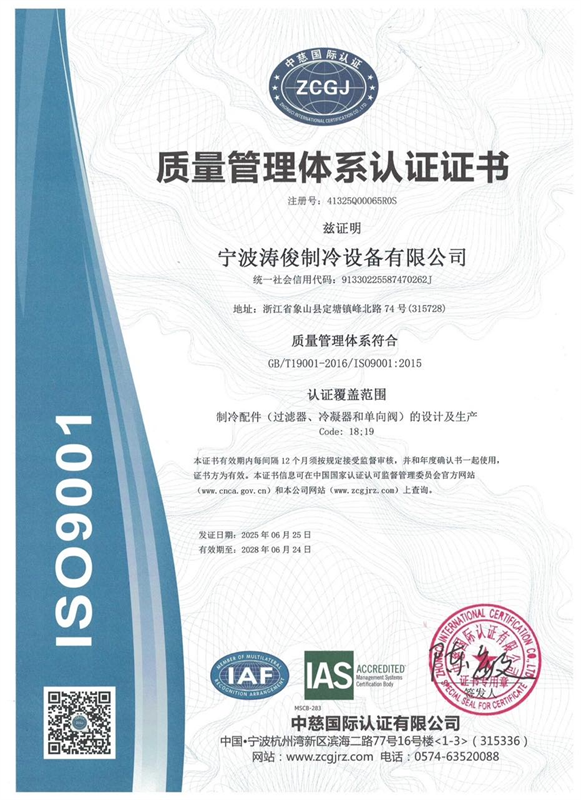

Juntao Refrigeration: Your Trusted ISO 9001-Certified OEM/ODM Partner

For Precision Refrigeration Components (Filter Driers, Condensers, Access Valves)

Main Certification Document

Detailed Scope of Certification

● Certified Excellence in Refrigeration Component Design & Manufacturing

Juntao Refrigeration (NINGBO TAOJUN REFRIGERATION EQUIPMENT CO.,LTD.) stands as a globally recognized leader in the design and production of critical refrigeration components. With our official GB/T19001-2016/ISO9001:2015 certification (Registration No.: 41325Q00065R0S), we demonstrate uncompromising commitment to quality in manufacturing filter driers, condensers, and access valves.

This certification, verifiable via China’s CNCA (www.cnca.gov.cn) and our partner Zhongci International (www.zcgirz.com), validates our advanced OEM and ODM capabilities for clients worldwide. For partners seeking reliable refrigeration component solutions, Juntao delivers innovation, precision, and supply chain security from our ISO-certified facility in Zhejiang, China.

Section 1: The Power of ISO 9001 Certification – Your Quality Guarantee

Why Certification Matters in Refrigeration Manufacturing

★ Design Excellence (ODM Strength)

Certified innovation in component engineering for thermal efficiency, durability, and compatibility.

★ Production Precision (OEM Strength)

Standardized manufacturing of refrigeration parts with traceable quality metrics.

★ Supply Chain Reliability

Annual surveillance audits (mandated under our certification) guarantee consistent output.

Juntao’s Certified Scope (Code 18;19):

Section 2: Deep Dive: Juntao’s Core Refrigeration Components – Engineered for Performance

◈ 2.1 Filter Driers: Protecting Your Refrigeration Systems

Juntao’s ODM/Design Capabilities:

Our engineering team excels in custom filter drier design (ODM). We optimize:

- ➤ Core Design: Molecular sieve selection & capacity calculation for specific refrigerant types (R134a, R404A, R410A, CO2 etc.).

- ➤ Structure: Shell material (steel/copper), pressure ratings (HP/LP), brazing integrity.

- ➤ Filtration Efficiency: Custom micron-level filtration media for contaminant removal (moisture, acid, particulates).

- ➤ Connection Types: Customizable inlet/outlet configurations (SAE, flare, solder).

Juntao’s OEM/Production Strengths:

High-volume filter drier manufacturing with:

- ● Automated desiccant filling & moisture control.

- ● Helium leak testing (< 1×10⁻⁷ Pa·m³/s standard).

- ● Burst pressure testing (exceeding ASHRAE standards).

◈ 2.2 Condensers: Maximizing Heat Transfer Efficiency

Juntao’s ODM/Design Capabilities:

We provide advanced condenser design solutions (ODM) focusing on:

- ➤ Thermal Performance: CFD-optimized fin-tube configurations (copper/aluminum) for maximum heat rejection.

- ➤ Application-Specific Design: Mini-channel condensers for compact systems, wire-and-tube for cost-efficiency, coil condensers for heavy-duty use.

- ➤ Material Science: Corrosion-resistant coatings (e.g., hydrophilic blue fin) for harsh environments.

- ➤ Refrigerant Compatibility: Designs optimized for R290, R32, R454B, and other next-gen refrigerants.

Juntao’s OEM/Production Strengths:

Precision condenser manufacturing featuring:

- ● Robotic welding ensuring consistent tube-fin bonds.

- ● Automated pressure testing (nitrogen/water).

- ● Strict cleanliness protocols (ISO Class 8 equivalent).

- ● High-volume production lines for air-cooled & evaporative types.

◈ 2.3 Access Valves: Precision Control & Serviceability

Juntao’s ODM/Design Capabilities:

Innovation in access valve design (ODM) includes:

- ➤ Valve Core Mechanisms: Schrader, ball, diaphragm types for diverse pressure ranges (up to 800 PSIG).

- ➤ Sealing Solutions: Advanced elastomers (HNBR, FKM) for extreme temperatures (-40°C to +150°C) and refrigerant compatibility.

- ➤ Body Materials: Brass, stainless steel options with chrome/nickel plating.

- ➤ Connection Standards: SAE, JIS, metric threads; sweat, flare, or O-ring face seal ends.

Juntao’s OEM/Production Strengths:

Reliable access valve manufacturing with:

- ● CNC machining centers ensuring micron-level tolerances.

- ● 100% automated leak testing (air under water).

- ● Torque & cycle life testing (10,000+ cycles standard).

- ● Custom branding (valve caps, body engraving).

Section 3: Juntao’s OEM & ODM Advantage – Beyond Certification

✅ 3.1 Full-Spectrum ODM Services: From Concept to Refrigeration Component

Leverage our certified design expertise for:

- ‣ Co-Development: Collaborative engineering based on your specs & application needs.

- ‣ Prototyping: Rapid 3D modeling, functional prototypes, testing validation.

- ‣ DFM (Design for Manufacturing): Optimizing designs for cost-effective, high-yield production.

- ‣ Regulatory Compliance: Designs meeting UL, CE, RoHS, REACH, NSF standards.

Keywords: refrigeration component design, ODM refrigeration parts, custom refrigeration solutions, co-development engineering, DFM for refrigeration.

✅ 3.2 Scalable OEM Manufacturing: Quality Meets Volume

Our certified production capabilities deliver:

- ‣ Flexible Capacity: Support from small batches (NPI) to high-volume runs (millions/year).

- ‣ Vertical Integration: Key processes (stamping, tubing, brazing, assembly) in-house for quality & cost control.

- ‣ Supply Chain Resilience: ISO-certified raw material sourcing & inventory management.

- ‣ Logistics Excellence: Global export packaging, documentation, and shipping.

Section 4: The Juntao Difference – Why Partner With Us?

✔ ISO 9001:2015 Certified Quality:

Audited systems ensuring every filter drier, condenser, and access valve meets exact specs.

✔ Proven ODM Innovation:

Certified design and production capability driving component performance.

✔ OEM Reliability & Scale:

Consistent, high-volume output meeting global demand.

✔ Transparency & Trust:

Certificate publicly verifiable (CNCA & Zhongci websites).

✔ Long-Term Partnership:

Certification valid until June 24, 2028 (with annual audits ensuring continuous improvement).

Section 5: Partner with a Certified Leader

Juntao Refrigeration is more than a supplier; we are your ISO-certified ODM/OEM partner for mission-critical refrigeration components. Our expertise in designing and manufacturing superior filter driers, condensers, and access valves is rigorously validated. We empower global brands with:

⚡ Innovation

Solve complex thermal challenges through collaborative ODM.

☆ Quality

Rely on certified, audit-proven manufacturing (OEM).

⚙ Efficiency

Optimize system performance with precision components.

🔒 Supply Chain Security

Partner with a stable, long-term certified manufacturer.