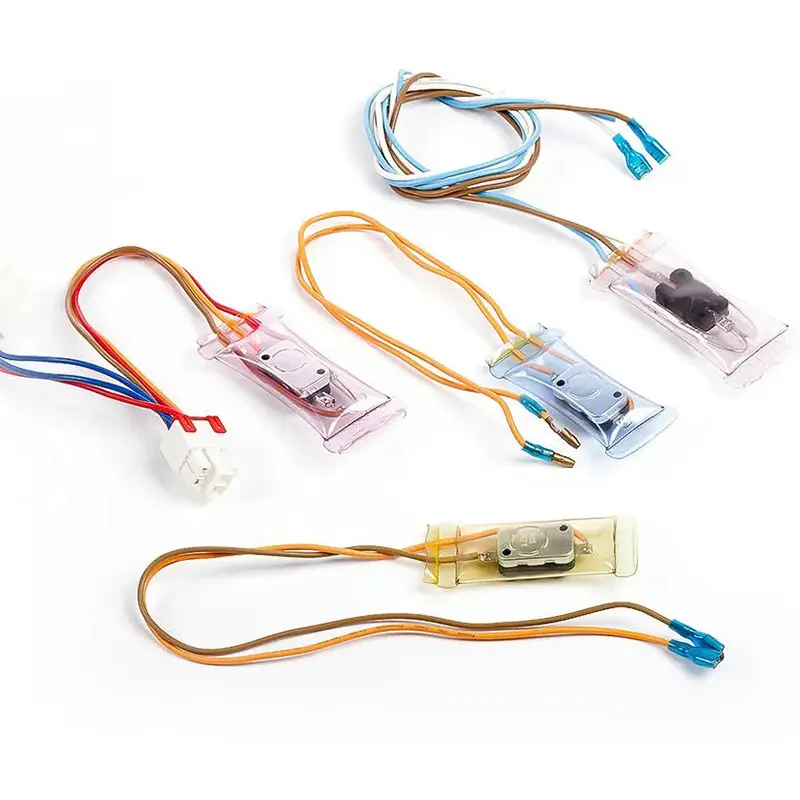

Defrost Timer & Thermostat

Defrost Timer & Thermostat

The defrost timer is a component used to control the defrosting program of refrigeration equipment. During the operation of the refrigeration equipment, the defrost timer can automatically start and stop the defrosting program according to the preset time interval, ensuring that the evaporator is defrosted in a timely manner and maintaining the efficient operation of the refrigeration system.

Application scenario

1. Household Air Conditioning

2. Commercial Air Conditioning

3. Industrial Air Conditioning

Feature

Precise Time Control: It can accurately start and stop the defrosting process according to the preset time intervals. This ensures that the evaporator undergoes defrosting at the appropriate time, preventing the frost layer from becoming too thick and affecting the refrigeration efficiency. At the same time, it prevents excessive defrosting, which could lead to energy waste.

● Strong Adaptability: There are various specifications and working modes available. It can be widely applied to different types and power ratings of refrigeration equipment, such as household refrigerators, freezers, air conditioners, as well as commercial refrigerated cabinets and cold storage facilities. It can provide matching defrost control according to the refrigeration requirements and operating environments of different devices.

● High Reliability: Made of high-quality materials and using advanced manufacturing processes, it has good stability and durability. It can maintain accurate time control and a stable working state during long-term operation, reducing the probability of failures. This ensures the normal operation of the refrigeration equipment and reduces maintenance costs.

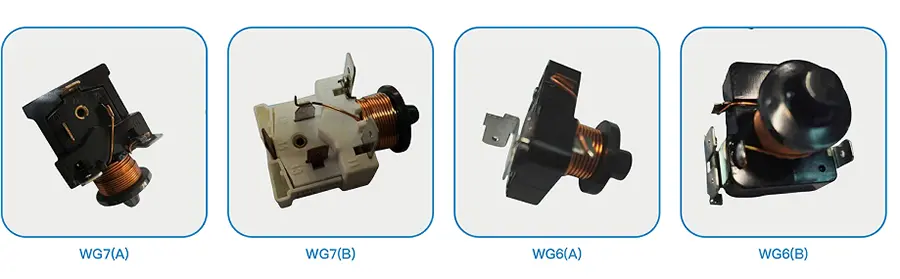

Series:

Material: PP shell + copper insert

Voltage: 110-220VAC

Frequency: 50 / 60Hz

Thermostat

It is mainly used for monitoring and controlling the temperature. By sensing the changes in the ambient temperature, it can automatically adjust the operating status of heating or cooling equipment to keep the temperature within the set range.

Application scenario

1. Household Air Conditioning

2. Commercial Air Conditioning

3. Industrial Air Conditioning

Feature

● Precise Temperature Control: It can accurately sense temperature changes and control the temperature to stay close to the set value. The accuracy can usually reach ±0.1℃ or even higher, ensuring the stability of the environmental or equipment temperature and meeting various precise temperature control requirements.

● Convenient Operation: Most of them are equipped with a simple and easy-to-understand operation interface. Whether it is a mechanical knob or button, or an electronic touch screen or digital display screen, users can easily set and adjust parameters such as temperature and mode.

● Multiple Control Modes: It has a variety of control methods, such as proportional control, integral control, derivative control, and their combinations (PID control), etc. According to different application scenarios and control objects, the appropriate control mode can be selected to achieve the best temperature control effect.

Starter

A starter is a device used to start various equipment or systems. It provides the initial power or signal to enable the equipment to transition from a stationary state to an operating state.

Feature

● Providing Initial Power or Signal: The core function of a starter is to provide the power or signal required for the equipment to start, enabling the equipment to smoothly transition from a stationary state to an operating state. For example, a motor starter supplies the appropriate voltage and current to the motor through a control circuit, enabling it to generate sufficient torque to overcome the initial resistance and start the motor.

● Having Multiple Starting Modes: Different types of starters have their own unique starting modes to meet the needs of different equipment and loads. For example, the direct - on - line starter is simple and suitable for small - power motors; the star - delta starter, autotransformer starter, and soft starter achieve the smooth starting of high - power motors through different step - down or current - limiting methods, reducing the impact of starting current on the power grid and equipment.

● Closely Cooperating with Equipment: The starter needs to closely cooperate with the equipment it controls and is designed and selected according to the characteristics and requirements of the equipment. For example, the computer starter is compatible with the computer's motherboard, power supply, and other hardware, following specific communication protocols and signal specifications to ensure the normal startup and operation of the computer.

Protector

Protector is a device used to protect electrical equipment, systems, or circuits from adverse effects such as over - voltage, over - current, and over - temperature.

Feature

● Real - time Monitoring: The protector can monitor the key parameters during the operation of the equipment in real time, such as current, voltage, temperature, pressure, etc., and always pay attention to the running state of the equipment. Once the parameters are abnormal, the protector can quickly respond and take timely protection measures.

● Having Diverse Protection Functions: The protector has a variety of protection functions for different abnormal situations. For example, the overload protector prevents the equipment from being damaged due to excessive load; the over - voltage and under - voltage protector protects the equipment from the influence of voltage fluctuations; the temperature protector avoids the equipment from malfunctioning due to overheating or over - cooling; the phase - sequence protector ensures the correct phase sequence of the three - phase power supply and prevents the motor from reversing.

● High Reliability: Protectors usually have high reliability, can operate stably in harsh working environments, and have strong anti - interference capabilities. They have gone through strict testing and verification to ensure that they can accurately and timely play a protective role when the equipment is abnormal, effectively protecting the safety of equipment and personnel.

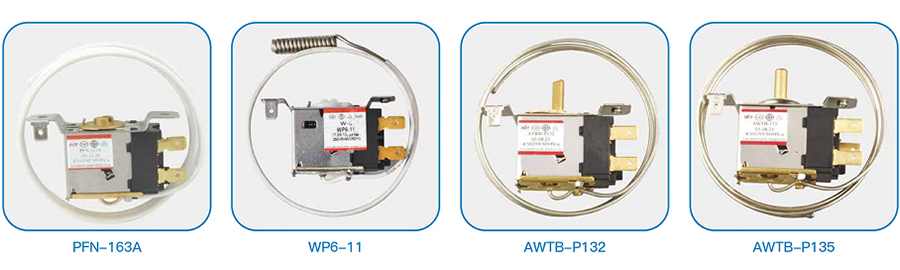

thermostat

A thermostat is a device used to control temperature. It can automatically adjust the temperature of the object being controlled according to the set temperature value, keeping it within a relatively stable range.

Feature

1. Precise and Diverse Temperature Control: The thermostat can accurately control the temperature, keeping it stable within the set range. It also has a variety of temperature control functions, such as temperature display, alarm, timing, and remote control, etc., which can meet the needs of different scenarios.

2. Simple Operation and High Reliability: It is easy to operate, and users can easily set the temperature and other operations. At the same time, it has good stability and durability, can work stably for a long time, and has excellent compatibility, being able to be adapted to various heating or cooling devices.

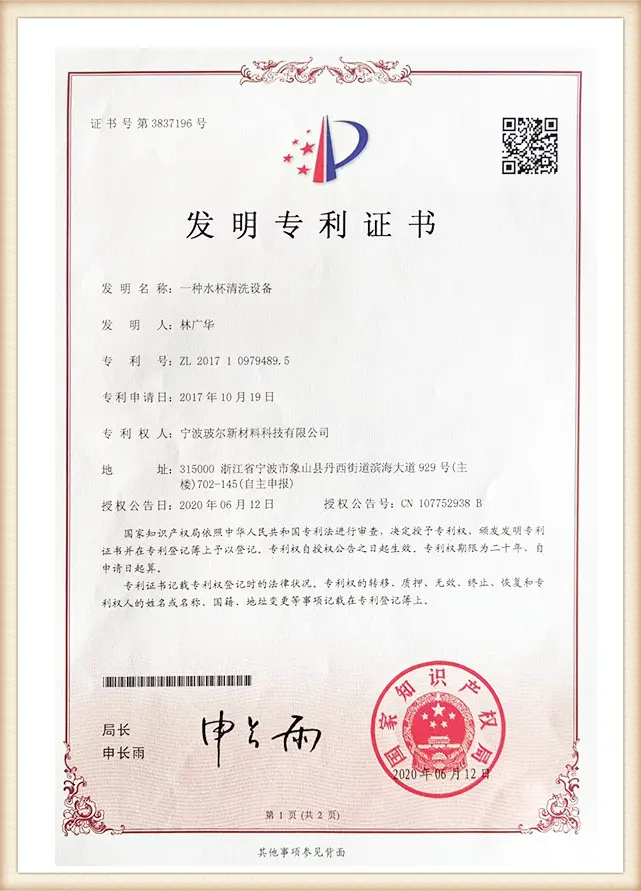

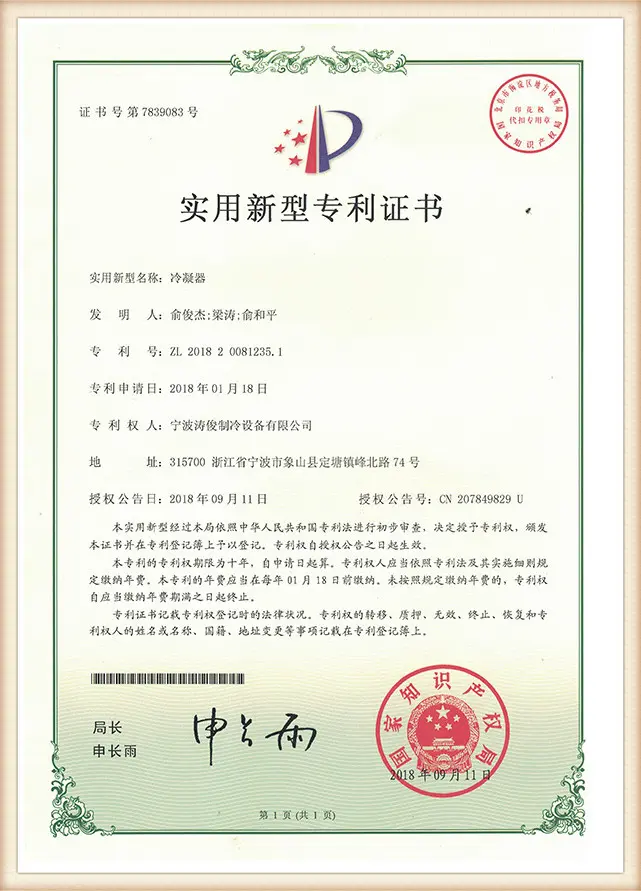

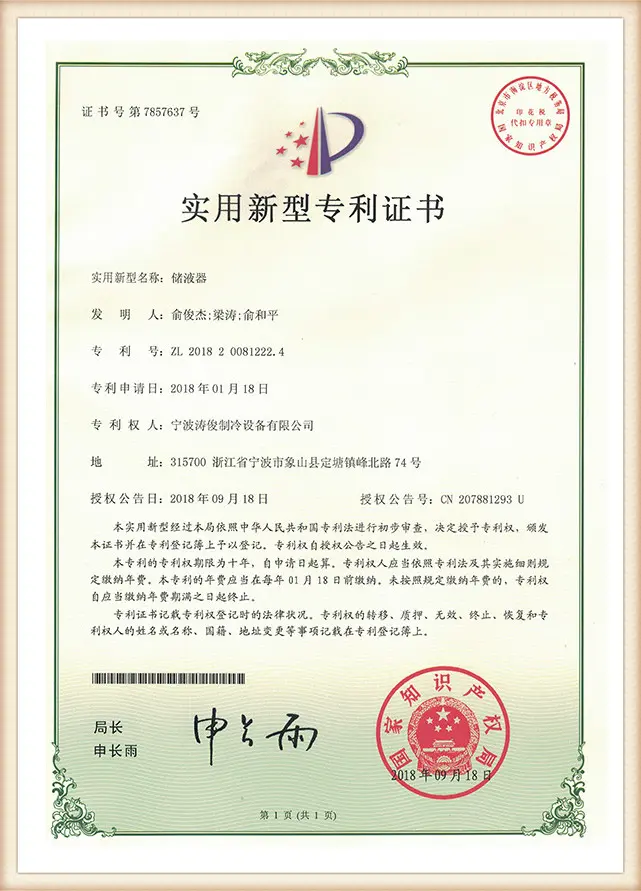

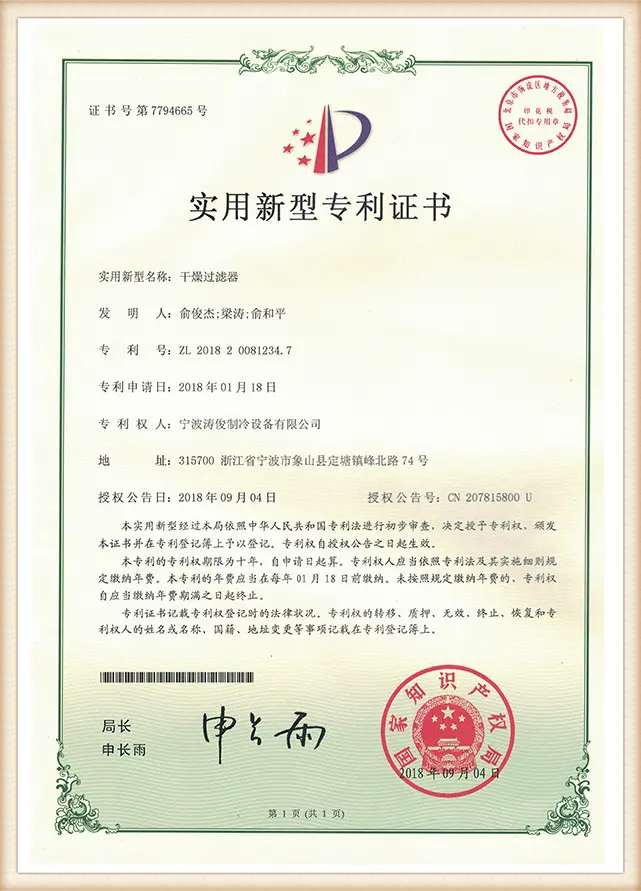

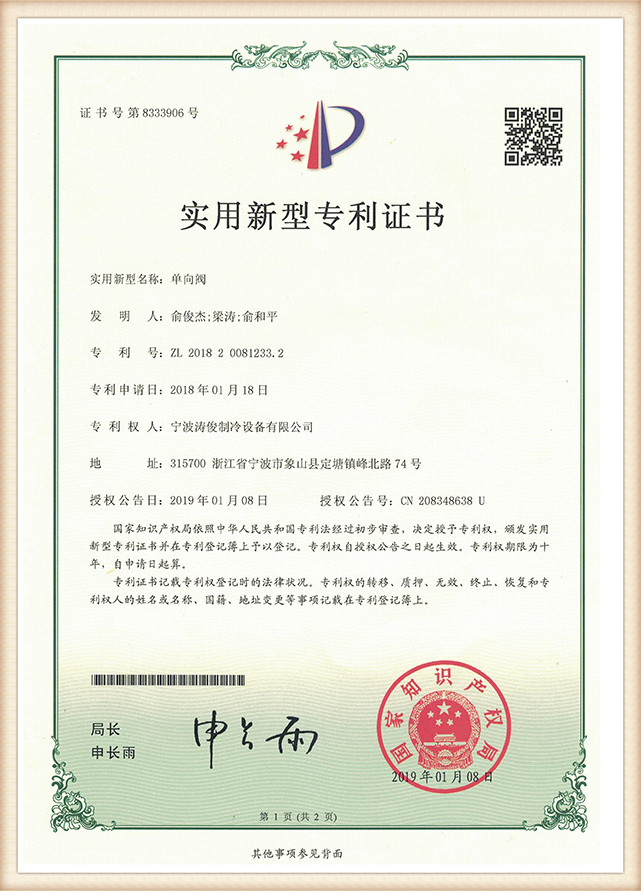

Certificates