Bundy tube

Characteristics

High Strength: The Bundy tube is made of high-quality low-carbon alloy steel material. After cold-drawing processing, it has high strength and hardness, and can withstand large pressure and impact force.

High Precision: Due to its advanced processing technology, the Bundy tube has high dimensional accuracy for both the inner and outer diameters, and good roundness, meeting the usage requirements of various high-precision equipment.

Good Flexibility: The Bundy tube has a certain degree of flexibility and can be bent and formed as needed, making it convenient for installation and use in different spaces and environments.

Corrosion Resistance: The surface treatment of galvanization or copper plating endows it with good corrosion resistance, enabling it to resist the erosion of various chemical substances and extend its service life.

Application Fields

Automotive Industry: The Bundy tube is widely used in the fuel system, braking system, and air conditioning system of automobiles. For example, in the fuel system, the Bundy tube is used to transport fuel. Its high precision and corrosion resistance can ensure the safe transportation of fuel and the stable operation of the system. In the braking system, the Bundy tube serves as the braking pipeline, which can withstand high pressure and ensure the reliability of braking.

Refrigeration Industry: In refrigeration equipment, the Bundy tube is often used as the pipeline for transporting refrigerants. Its good corrosion resistance and flexibility enable it to adapt to the low-temperature environment and complex pipeline layout requirements in the refrigeration system.

Hydraulic System: The Bundy tube is also applied in various hydraulic systems as the pipeline for transporting hydraulic oil. Its high strength and high precision can ensure the pressure transfer efficiency and stability of the hydraulic system.

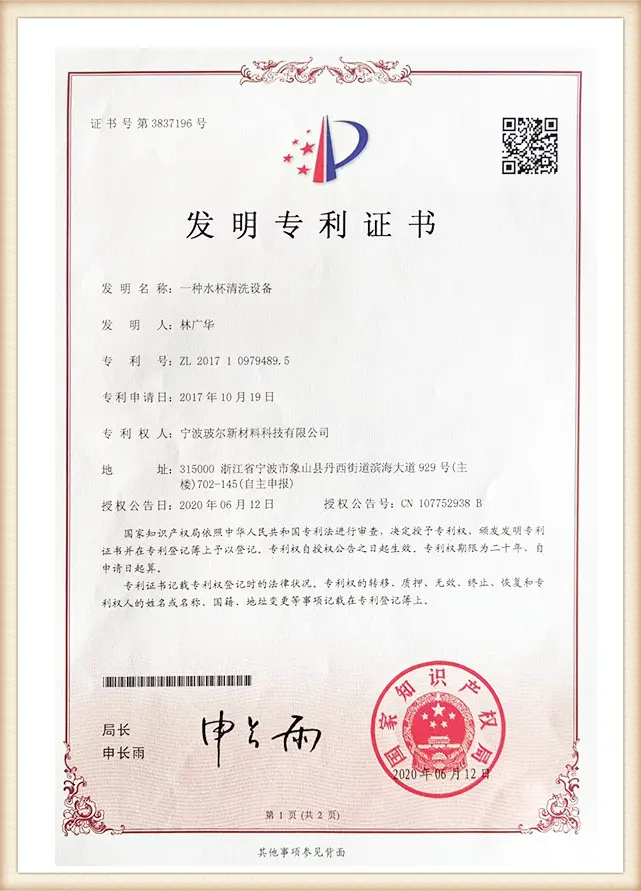

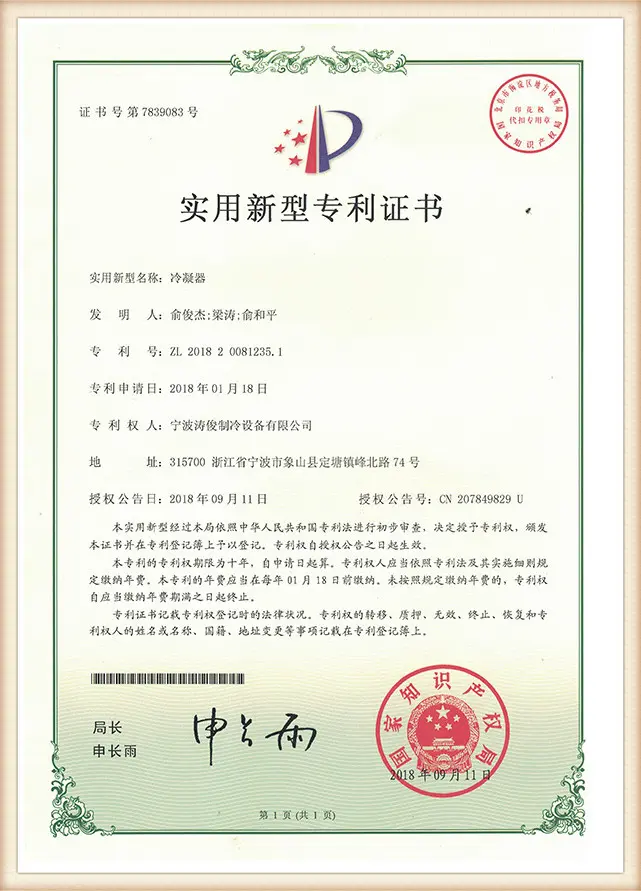

Certificates