Choosing the right Heat Pump Filter Drier is crucial for maintaining optimal system efficiency, especially in a world where energy conservation is paramount. As noted by HVAC expert Dr. Jane Mitchell, “The efficiency of a heat pump system is deeply interconnected with the quality of the filter drier; selecting the appropriate one can result in significant energy savings and prolonged equipment life.” In the industry, filter driers play a vital role in safeguarding the system against moisture and contaminants, ensuring peak performance throughout its operational lifespan.

In this guide, we will explore the essential factors to consider when selecting a Heat Pump Filter Drier, focusing on the attributes that contribute to enhanced efficiency and reliability. With insights from leading professionals and the latest advancements in technology, we aim to equip you with the knowledge necessary to make an informed choice. Understanding the nuances of filter drier specifications, compatibility with various refrigerants, and installation techniques will empower you to optimize your heat pump system effectively.

Join us as we delve into the 2025 top selections and expert recommendations for achieving unparalleled system efficiency.

When considering the efficiency of heat pump systems, the role of filter driers cannot be overlooked. These components serve as critical barriers against moisture and contaminants, which can significantly impact system performance. According to a report by the Air Conditioning, Heating, and Refrigeration Institute (AHRI), a clean refrigerant flow is essential for maintaining the efficiency of heat pump operations, as impurities can reduce heat transfer and result in increased energy consumption. Proper filtration helps to keep the system running smoothly, ensuring optimal heat exchange and prolonging the lifespan of the unit.

Moreover, the selection of the appropriate filter drier is paramount for achieving maximum efficiency. The ability of a filter drier to absorb moisture is measured in grams and can vary by design. Studies have shown that systems equipped with a high-capacity filter drier can enhance overall efficiency by up to 20%, as they effectively mitigate the risks associated with liquid refrigerant contamination. In choosing the right filter drier, technicians should consider factors such as the refrigerant type, system capacity, and ambient conditions to ensure they enhance the operational efficiency and reliability of the heat pump system.

This chart illustrates the efficiency impact of different types of heat pump filter driers. Selecting the right filter drier can significantly enhance the system's performance, as shown in the varying efficiency percentages across different types.

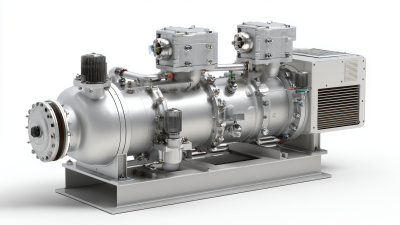

When selecting the right heat pump filter drier, understanding the different types available and their specific applications is crucial for optimal system efficiency. There are two primary categories of filter driers: liquid line filter driers and suction line filter driers.

When selecting the right heat pump filter drier, understanding the different types available and their specific applications is crucial for optimal system efficiency. There are two primary categories of filter driers: liquid line filter driers and suction line filter driers.

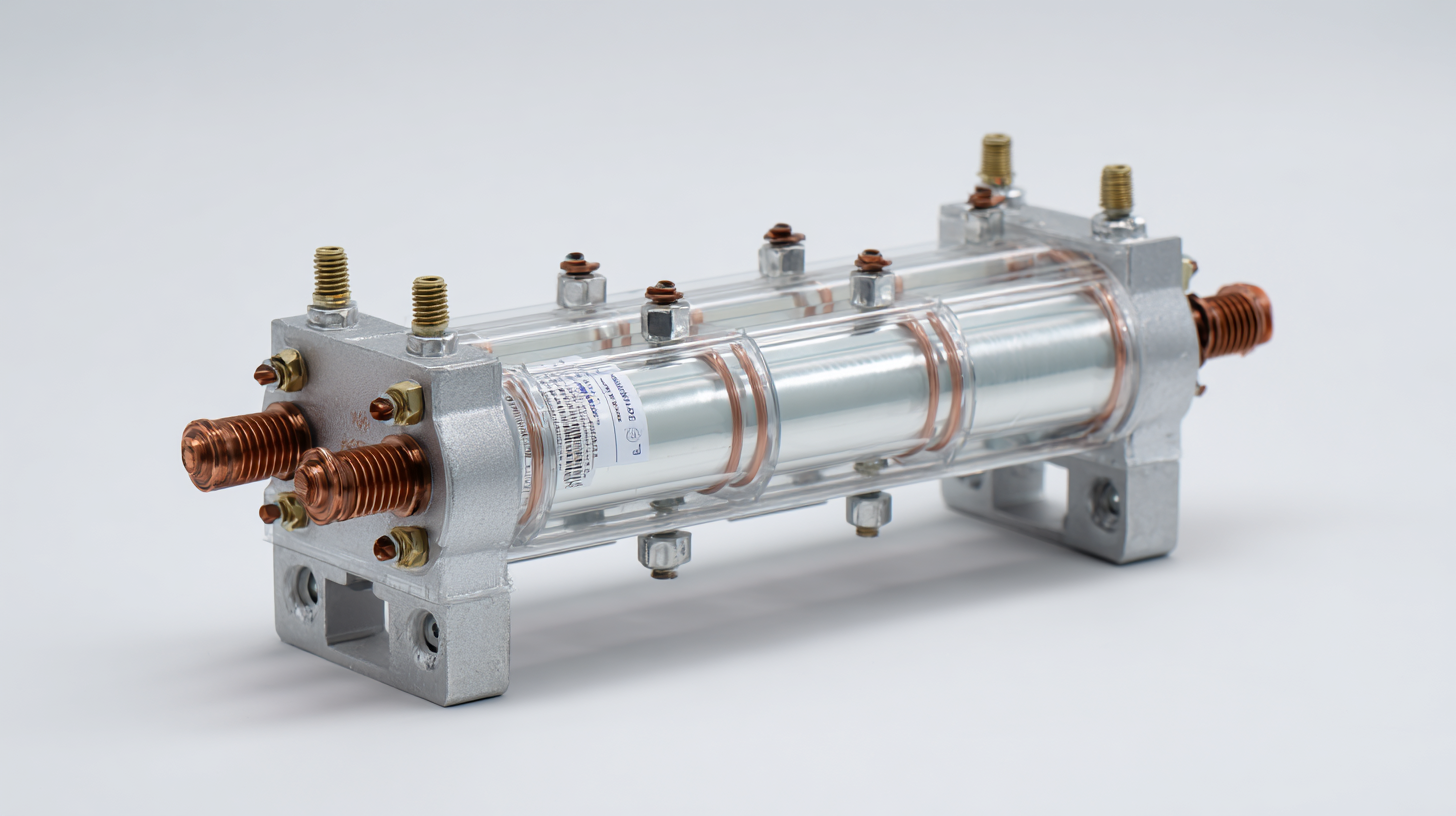

Liquid line filter driers are typically installed in the refrigerant line between the condenser and the expansion device. They are designed to remove moisture and contaminants, ensuring that the refrigerant entering the expansion valve is clean and dry, which helps prevent system malfunctions.

On the other hand, suction line filter driers are placed in the line that delivers refrigerant vapor to the compressor. Their main function is to capture any contamination that may have entered the system after the evaporator. These filter driers are essential in preventing damage to the compressor and maintaining the overall health of the heat pump system.

Depending on the system configuration and the specific contaminants present, choosing the right type of filter drier can significantly enhance the efficiency and longevity of the heat pump, ensuring it operates at peak performance.

When selecting a heat pump filter drier, there are several key factors that can significantly affect system efficiency. One of the most critical considerations is the type of refrigerant being used. According to the International Institute of Refrigeration, the choice of filter drier should align with the specific refrigerant's properties, as different refrigerants can cause varying chemical interactions and moisture absorption rates. Selecting a compatible filter drier ensures optimal performance and longevity of your heat pump system.

Another important factor is the capacity and size of the filter drier. Industry standards suggest that the filter drier should be sized according to the heat pump system’s design flow rate. A report from the Air Conditioning, Heating, and Refrigeration Institute indicates that an improperly sized filter drier can lead to pressure drops, affecting overall system efficiency. Proper sizing not only ensures the drier can effectively trap debris and moisture but also maintains optimal pressure levels in the refrigerant line.

**Tip:** Always check the manufacturer’s specifications and consider using a filter drier with a sight glass for easy monitoring of moisture levels.

Additionally, installation location plays a vital role. Filters should be installed in the liquid line close to the expansion device, where they can most effectively prevent contaminants from entering the evaporator. The ASHRAE Handbook highlights that maintaining cleanliness in the refrigeration circuit is essential for maximizing efficiency and reliability.

**Tip:** Regular maintenance and timely replacement of the filter drier can help avoid system failures and costly repairs.

| Filter Drier Type | Refrigerant Compatibility | Moisture Removal Capacity (g) | Operating Temperature Range (°F) | Connection Size (inches) |

|---|---|---|---|---|

| Standard Filter Drier | R-22, R-410A | 10 g | 30 to 130 | 3/8" |

| Bi-directional Filter Drier | R-134A, R-404A | 12 g | 20 to 140 | 3/8" |

| Desiccant Filter Drier | R-32, R-410A | 15 g | -10 to 150 | 1/2" |

| Core Filter Drier | R-410A, R-404A | 8 g | 30 to 120 | 3/8" |

When selecting a heat pump filter drier, many users make common mistakes that can hinder system efficiency. One frequent error is underestimating the importance of the drier's micron rating. A filter drier with a rating that is too high may allow moisture and debris to pass through, ultimately leading to compressor failure. According to the Air-Conditioning, Heating, and Refrigeration Institute (AHRI), 70% of compressor failures can be attributed to contaminants in the refrigerant system, indicating the critical role a proper filter drier plays in maintaining system integrity.

Another common pitfall is disregarding the compatibility of the filter drier with the refrigerant type used in the heat pump system. For instance, using a drier designed for R-410A refrigerant in a system intended for R-22 may lead to chemical reactions that can damage components, costing homeowners thousands in repairs. Data suggests that choosing the wrong filter drier can significantly decrease energy efficiency by up to 15%, reinforcing the necessity for careful selection to optimize performance and longevity.

When it comes to maintaining the efficiency of your heat pump filter drier, regular cleaning and upkeep are crucial. Many homeowners overlook the importance of these tasks, which can significantly impact appliance performance and energy bills. According to industry reports, dirty filters can cause a drop in efficiency by up to 15%, leading to increased operational costs and potential breakdowns. Therefore, it’s imperative to check and clean your heat pump filter drier every few months to ensure optimal airflow and system performance.

In addition to cleaning, it's essential to inspect for any signs of wear or damage regularly. Experts recommend checking for leaks or corrosion, which can impact not only the filter drier but the overall heat pump system as well. Regular maintenance, such as replacing the filter every six months to a year, can prevent larger issues down the line. Investing a little time in these maintenance tasks can save homeowners thousands of dollars by extending the life of their appliances and ensuring they operate at peak efficiency. By prioritizing these tips, you can enhance your heat pump system’s longevity and performance, making it a wise choice for sustainable home heating and cooling.